CapCN-Semi Pro Drawer Type Semi-auto Capsule Filling Machine

CapCN-Semi Pro Drawer Type Semi-auto Capsule Filling Machine

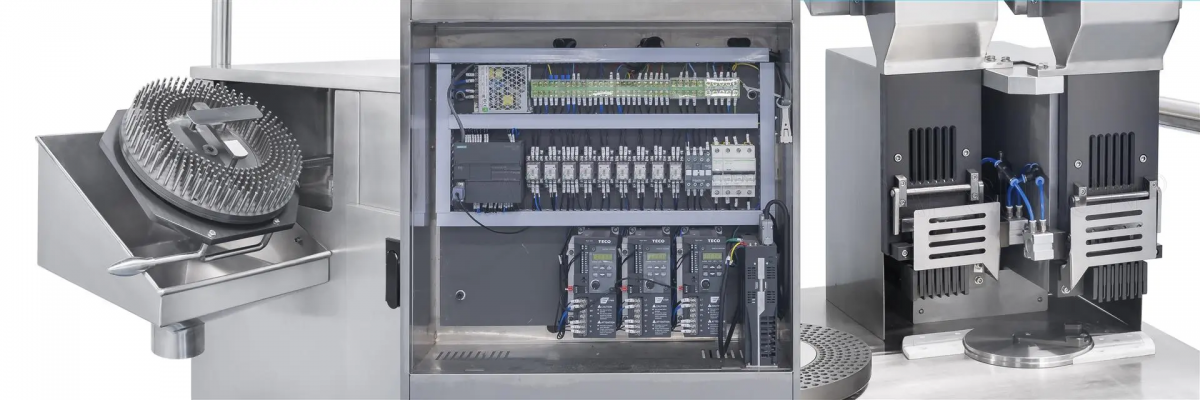

This machine adopts programming control system, touch panel operation, stepless frequency conversion speed regulation, pneumatic joint control, and electronic automatic counting device, which can automatically complete the capsule positioning, separation, filling, locking and other actions.

The filling dose is accurate and the operation is convenient. The body and work surface are made of stainless steel, and the product meets the requirements of GMP. It is suitable for capsule filling of powdered and granular medicines.

Advantages

Practicality upgrades

- Use external hexagon screws:more convenient to clean,solves the cross-contamination of materials.

- Use oxidized capsule tray: A protective film is added to the surface to enhance the corrosion resistance, surface hardness and wear resistance of the surface layer, prolong the service life of the grinding disc, and is easy to clean.

- The installation of the main power switch can directly cut off all work, without powering off to open the electrical box and then turn off the power.

- The position of the emergency stop button has been changed, you can reach out and touch it. It’s easier to deal with in case of emergency.

- The discharge port is designed to be detachable, which solves the problem of difficult cleaning of material residues at the discharge port; a new mold tray rack is installed to make the operation of multiple trays more convenient.

Security upgrade

- The width of the work surface reaches about 85 cm, which increases the safety distance

- The edge of the work surface has been changed from the original right angle to the rounded corner

- Locking operation time reduced from 18 seconds to 12 seconds

- The capsule feeding mechanism is moved from the machine table to below the machine table, which greatly reduces the operator’s physical expenditure, and effectively relieves operator fatigue.

- Material recovery system reduces material waste and material recovery speed, and reduces environmental pollution to the entire workshop

Reconfigurable upgrade

- The domestic vacuum pump was upgraded to the vacuum pump of German Becker company

- The electrical box is equipped with a lash sensor, and the machine will automatically stop once the door of the electrical box is opened, which can better protect personal safety.

- The innovatively designed double-head full-automatic capsule feeding mechanism of the capsule feeding station doubles the capsule feeding speed. The machine can be equipped with double grinding discs, which can continuously feed capsules and fill materials, greatly improving production efficiency.

| Model | CapCN-Semi Pro |

| Output | 1-42000 pcs/hour |

| Applicable capsules | 0#, 1#, 2#, 3#, 4#,5# |

| Total power | 3.2 kw |

| Vacuum Pump(evacuation rate) | 40m3/h |

| Air pressure | 0.03m³/min,0.7MPa |

| Dimensions(LxWxH) | 1140*700*1630mm(L*W*H) |

| Whole weight | 400kg |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China