The technology behind tablet coating has improved greatly, from simple sugar coatings to sophisticated film coatings. Today, automatic tablet coating machines give pharmaceutical manufacturers more control and efficiency in applying these coatings.

This guide looks at the world of these automated systems. It examines the different types of machines, their key automation features, essential maintenance procedures, and common questions.

What are Different Types of Tablet Coating Machines?

Different production needs usually mean different types of tablet coating machines available. The common ones include standard coaters, fluid bed coaters, and continuous systems.

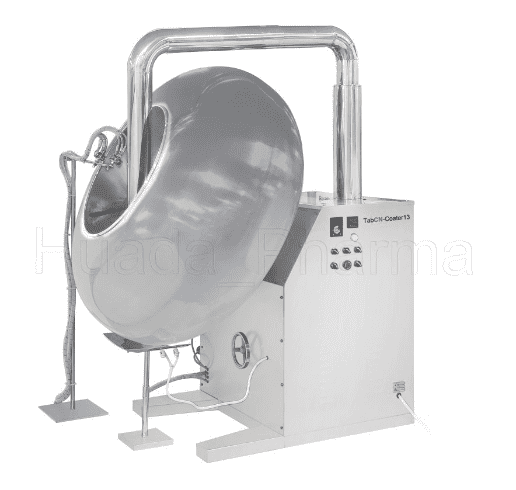

Standard Tablet Coating Machine

The standard type of tablet coater is equipment used for film coating. It's generally good for many formulas, and the coating process is fairly simple.

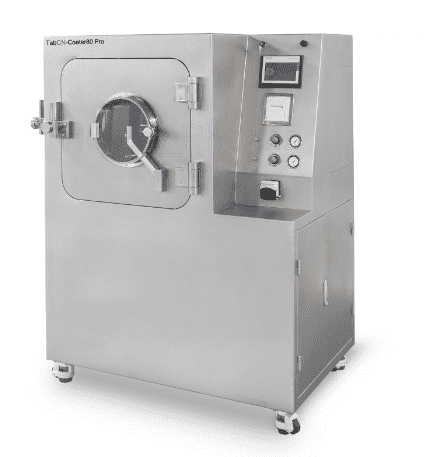

Perforated Tablet Coating Machine

Perforated tablet coaters use a drum or pan with air flowing through it. This lets the air move around better, which helps the tablets dry faster. This design gives you even coatings and super-fast cycle times. That's essential for getting the job done fast.

Fluid Bed Tablet Coating Machine

This machine is great because it can coat and dry at the same time. A stream of air picks up the tablet, ensuring the coating is spread evenly. You've got total control over the spray, airflow, and drying temperature.

Side-Vented Tablet Coating Machine

If you're making a lot tablets at once, side-vented coaters are the way to go. Not all coaters have this feature. They're often the best because you can control the temperature and humidity really well. They're also extremely efficient, making them a great choice for producing large quantities.

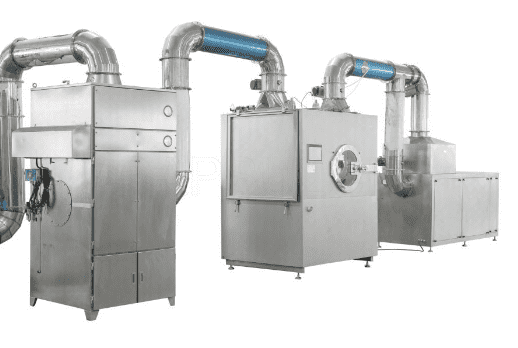

Continuous Tablet Coating System

This continuous tablet coating system keeps running without need to pause. This helps keep the final product quality consistent, even when you're producing a lot. It makes the whole production process better and costs less money.

What are the Important Technical Specifications of a Tablet Coating Machine?

When choosing a tablet coating machine, you should think about the technical specifications. That way, you can make sure you get the right machine for your production needs.

Machine Size

Firstly, you should take how big the machine is into account, because that'll obviously affect the amount of floor space you've got. Make sure you always pick a machine that'll fit in your production area.

Load Capacities

Lot capacities present the amount of product you can coat at once. Choose a coater that meets your production needs.

Output and Airflow Needs

Consider the machine's output and airflow needs. Good airflow ensures that materials are properly coated and dried. If don’t have proper airflow, a coating may not be complete.

Thermal Control

The proper temperature will ensure that the coating process is done well and that the coating material has good quality. You should also think about how the coating machine uses heat.

Spraying Pressure

This will affect how even the coating is. The thickness of the coating can change as the spray pressure changes. Thus, it is essential to use the right spray pressure with the right formula.

What are the Common Functions of an Automatic Tablet Coating Machine?

Nowadays, tablet coating machines often have many automated functions that make them much more efficient and accurate. And below are the most common ones:

1. Formula Storage

The automatic tablet coaters make coating procedures easier and more convenient. They allow you to reuse previous coatings. Once you store a successful formula, you can quickly recall it using its designated number. This ensures that the product quality stays the same every time it's produced.

2. Instant Process Feedback

The machines give immediate updates on the coating process as it happens. This allows operators to check and change important variables like temperature, pressure, and other parameters right away.

3. Production Record Keeping

The machines automatically track production details. They are significant for following the rules and for audits. They help you keep track of how each batch of products is doing, so you can find and fix any problems.

How to Maintain Your Automatic Tablet Coating Machine?

If you want your tablet coating machine to last, you have to take care of it. Here are the key areas you need to focus on:

Spray Applicators

Keep your spray applicators clean and up-to-date. A blocked applicator can reduce the quality of the coating. Follow the manufacturer's instructions for cleaning.

Air Intake Filters

Change your air intake filters regularly. If you notice a decrease in airflow and performance, it's likely time to replace them. Include this in your regular maintenance checks.

Mechanical Drive Parts

Check the drive parts for signs of wear and tear. You should keep these parts working well so that everything runs smoothly. If you hear any unusual sounds or feel any unusual vibrations, stop what you're doing right away and take actions to solve the problem.

Coating Pan Interior

Look closely at the pan's interior surfaces for scratches or buildup of coating material. This can disrupt the coating process. As part of your quality control procedures, clean and inspect these surfaces regularly.

Electronic Control Systems

Problems with the control systems can bring production to a standstill. Perform routine diagnostic checks on these systems. Keep system software up to date to prevent potential problems.

FAQs about Automatic Tablet Machines

- What are the Good Manufacturing Practice (GMP) requirements for coating equipment?

GMP requirements mean that processes and components have to be confirmed and can't change. We also need to be able to trace everything right back to where it came from. The equipment has to be designed so that it's easy to clean and maintain. That's why it's necessary to meet product safety and quality standards.

- What are the machine compatibility requirements?

Tablet coating machines should integrate easily with existing manufacturing setups. They need to work seamlessly with material handling and mixing equipment and be efficient to use.