Carton packaging is everywhere. It's used in pharmaceuticals, food, cosmetics, and consumer goods. Businesses rely on it because it offers a customizable way to make their product stand out and be protected. But behind the scenes, producing carton packaging comes with some challenges.

These issues may slow down production, increase costs, and affect product quality. The good news? There are solutions! In this post, we'll break down the most common carton packaging production challenges and share practical ways to fix them. Let's dive in!

7 Common Challenges in Carton Packaging Production and Their Solutions

Let's take a look at common challenges, so you can pinpoint what your business might be dealing with.

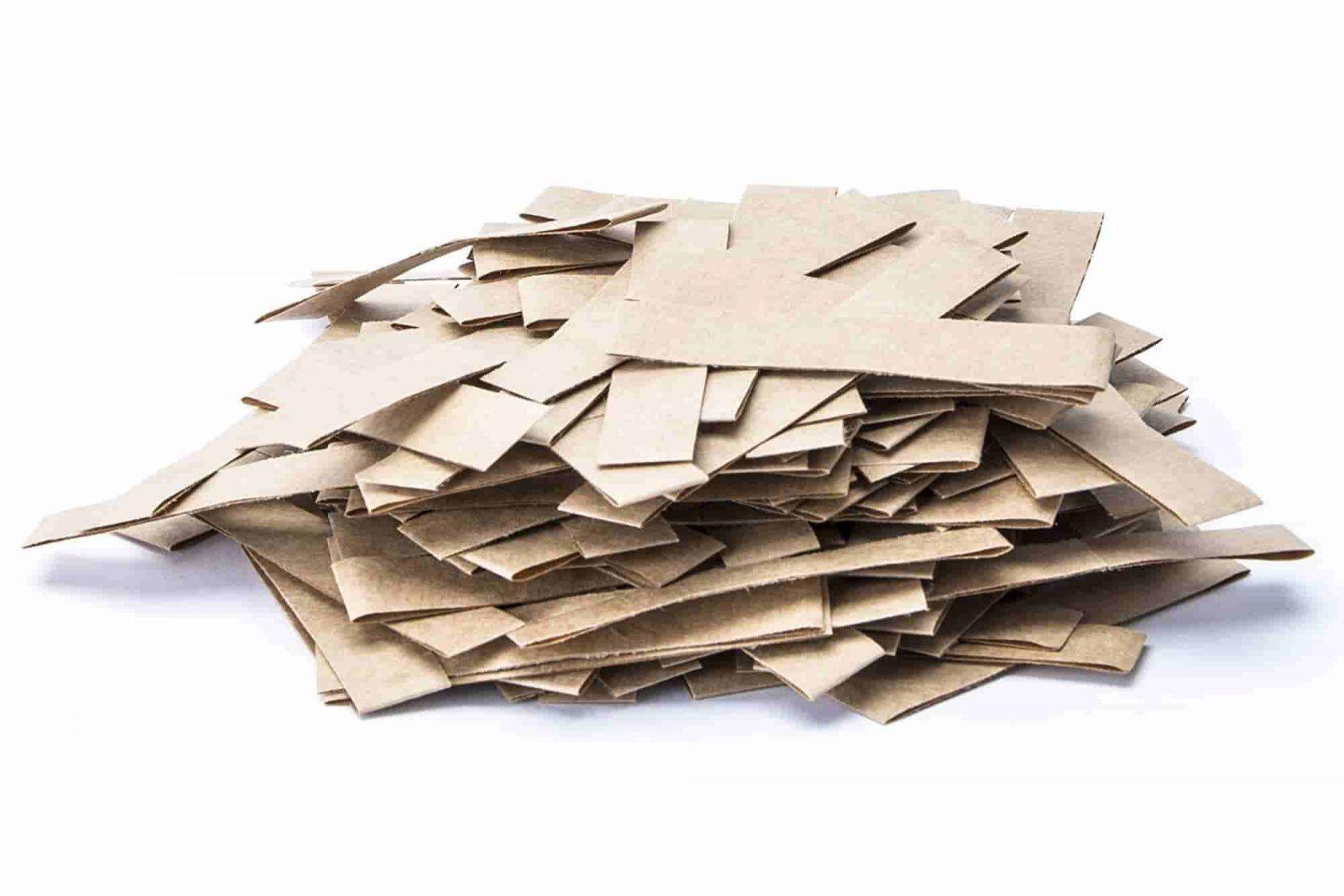

Challenge 1: Material Waste and Efficiency

Problem:

Material waste is a big challenge in carton packaging. Using too much material increases costs and harms the environment. Many packaging lines create more scrap than needed because of poor cutting, wrong carton sizes, or old machines. With growing pressure to cut waste and reduce carbon footprints, manufacturers need to make their packaging processes more efficient.

Solution:

- Try tweaking how you cut cardboard—maybe use software to map out precise patterns. This way, you'll make the most of each sheet and end up with less scrap.

- Look into more lightweight yet sturdy paperboard or thin corrugated cardboard. These materials are easier to handle and still protect products.

- Newer machines can fold, pack, glue, and seal faster and with fewer errors. Some even adjust box sizes automatically, which means less wasted material when switching between products.

- Turn extra carton pieces into small packaging inserts, protective padding, or even test prototypes. You could even partner with local artists or schools who might use them for projects—anything beats tossing them out.

Challenge 2: Design and Customization Demands

Problem:

Customers today want unique, eye-catching packaging that stands out. Brands often request custom carton shapes, colors, and printing details to match their image. Small batch orders with different designs can also create inefficiencies, making it hard to keep up with demand while staying profitable.

Solution:

- Switch to digital printers—they're way faster for custom labels or designs. Need to tweak a logo or add a seasonal promo? Just update the file and hit print. Perfect for small batches or last-minute changes without slowing things down.

- Go for modular machines. They come with swappable parts or settings. They handle different box sizes, shapes, or designs by just adjusting a few components. Saves time and money when switching between product lines or seasonal runs.

- Create design templates with flexible zones—like slots for changing text, images, or colors. This keeps your branding consistent but lets you customize for specific products or markets quickly. Bonus: You won't waste time rebuilding layouts from scratch every time!

Challenge 3: Material Costs and Availability

Problem:

Material costs keep rising, making it tough for manufacturers to stay profitable. Prices go up and down due to supply chain issues, economic changes, and high demand. When materials run low, production slows, deadlines get missed, and customers aren't happy. Finding affordable and readily available materials is a constant challenge in carton packaging.

Solution:

- Partner with a few trusted suppliers instead of sticking to just one. That way, if one runs into delays or shortages, you've got backups ready to go. Plus, having options lets you compare quality and negotiate better deals.

- Keep an eye on material prices and stock up when they drop. Buying in bulk often locks in discounts, especially for stuff you use regularly. Just make sure you've got the storage space so it doesn't pile up unused.

- Explore cheaper or more readily available substitutes—like swapping out a pricey plastic for a recycled paper blend or a locally sourced option. Test them first to ensure they hold up, but you'll often find they work just as well.

- Rethink your packaging design. Trim excess layers, shrink box sizes, or use clever folds that need less material. Tools like 3D modeling software can help spot waste without making boxes flimsy.

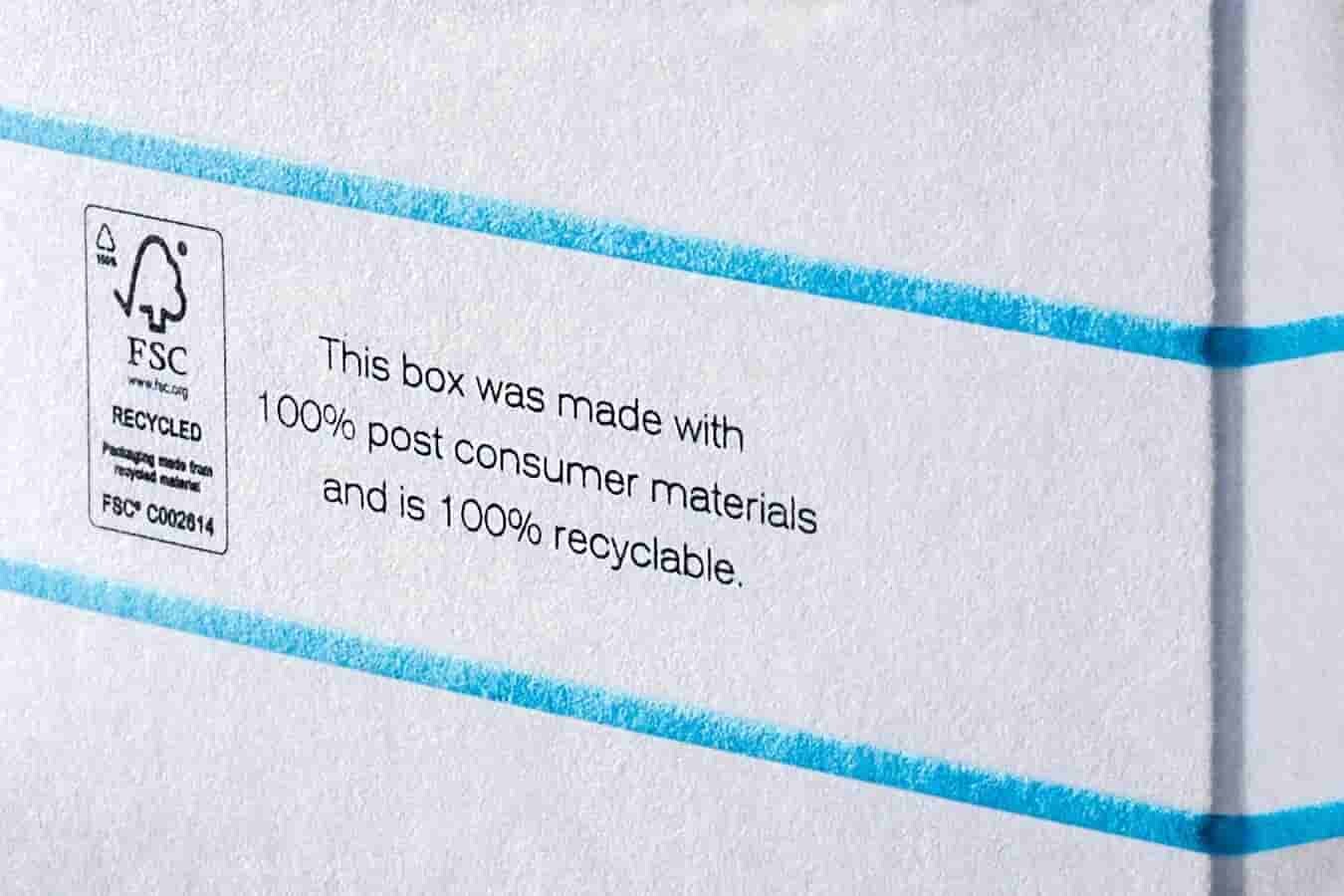

Challenge 4: Sustainability and Eco-Friendly Practices

Problem:

More businesses want to go green, and governments are setting stricter rules to reduce waste. Yet, making packaging eco-friendly isn't always simple. The challenge is that sustainable materials can be pricey. Not all of them work well with existing machines. Companies need to find a way out without slowing down production or raising costs too much.

Solution:

- Think about swapping plastics for stuff like cornstarch packaging or recycled paper. These break down naturally in landfills or can be easily recycled. Attach a "biodegradable" or a "100% recyclable" label to the cartons. Your customers are gonna love seeing it.

- Replace old, clunky equipment with ENERGY STAR-rated models. Look for features like automatic shut-off modes or slower idle speeds. Over time, the savings on power bills add up!

- Try using software to design 3D models for your packaging. Test thinner but tougher materials. Or try folding patterns that stay sturdy with fewer flaps. Slimmer designs mean less waste and cheaper shipping!

- Add simple icons or instructions on the packaging. Post quick videos on social media showing how to peel off labels before recycling. Partner with local recycling programs to share drop-off tips.

Challenge 5: Compliance with Regulations and Safety Standards

Problem:

Following packaging regulations is a must. However, rules change often. For instance, starting December 30, 2025, EU packaging must not use materials from deforestation sources, according to a new law (EUDR) that aims to stop deforestation. This includes cartons, boxes, and other containers made of paper, paperboard, or cellulose fibers. If companies don't meet these requirements, they can face fines, product recalls, or even legal trouble.

Solution:

- Stay on top of regulation changes by checking for updates every few months. You can set a reminder on your calendar or sign up for industry newsletters. If rules shift, tweak your workflows quickly to avoid fines or hiccups.

- When buying new equipment, do a little research to find machines with safety certifications or labels approved for your industry. A quick chat with suppliers can help confirm they meet current standards.

- Hold short training sessions every quarter to refresh your team on compliance basics. Use real-life examples. Keep a simple log to track who's attended and what you've discussed.

- Reach out to a local industry expert or join an industry group to double-check your work. They'll spot gaps you might miss, like a new rule about packaging materials or waste disposal.

Challenge 6: Supply Chain Disruptions

Problem:

Supply chain issues make it hard for manufacturers to get materials when they need them. In 2021, global shipping delays caused big shortages of paper and cardboard, making packaging production even harder. Rising fuel costs and factory shutdowns during the pandemic made it worse. Companies had to pay more or wait longer for materials. When supplies are late, production slows, deadlines get pushed back, and customers get frustrated.

Solution:

- Try partnering with a few backup suppliers in case your main one runs into issues. That way, if one can't deliver due to unexpected delays or shortages, you've got alternatives ready to step in.

- It's smart to keep a little extra of your most critical items, maybe 10-15% more than you need. Just check your stock levels regularly so nothing expires or takes up too much space.

- Don't wait until you're almost out. Order supplies a few weeks before you think you'll need them. If shipping delays or sudden demand spikes happen, you won't panic and can deal with it more confidently.

- Set up tracking systems, like real-time shipment updates, to see where your orders are at all times. If something's stuck or delayed, you'll catch it early and can adjust your plans.

- Treat your best suppliers like partners. Check in regularly, pay invoices on time, and be clear about your needs. A good relationship means they'll prioritize your orders and might even give you a heads-up about potential issues.

Challenge 7: Keeping Up With Technological Advances

Problem:

Technology is changing fast. New machines, 3D printing, and AI make production faster and more efficient. If companies don't keep up, they might fall behind competitors who use smarter technology. Future carton packaging will use technologies like augmented reality, AI-powered quality checks, robotic packaging systems, and smart packaging to improve the consumer experience and reduce waste.

Solution:

- Put some budget into R&D (research and development) to test out fresh ideas and tools. Even small experiments can lead to big breakthroughs and keep you ahead of competitors.

- Stick with modular systems. These machines allow for swapping out and upgrading parts easily later. That way, you won't have to start from scratch every time tech improves. It saves time and money.

- Keep your team sharp with regular training sessions. Whether it's workshops or online courses, make sure everyone's up to speed on the latest carton packaging technologies and methods.

- Team up with tech companies or startups that specialize in your field. They'll often share insider knowledge or early access to tools you wouldn't find on your own. Or you can just hire talents in these domains, like AI, 3D printing, robotics, and the IoT.

- Follow industry newsletters, podcasts, or social media accounts that talk about packaging trends. The more you know, the faster you can spot opportunities—or dodge problems before they hit.

The Bottom Line

These days, carton packaging manufacturers are dealing with quite a few challenges. Still, with the right strategies, you can tackle them head-on. If you're feeling overwhelmed by these challenges right now, we hope this blog can really help out and provide some useful insights to make your carton packaging business a little easier!