SFK-700 Capsule Filling Machine

Fully Automatic Capsule Filling Machine SFK-700

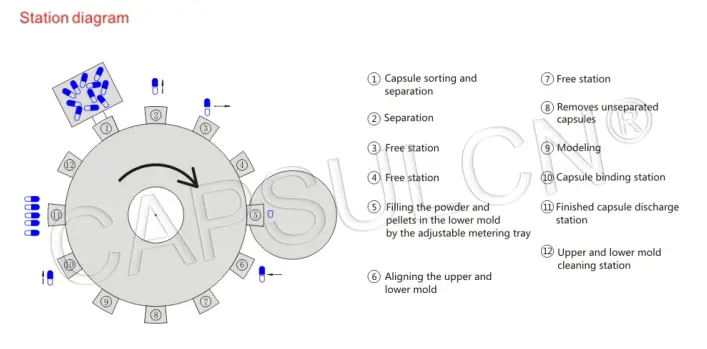

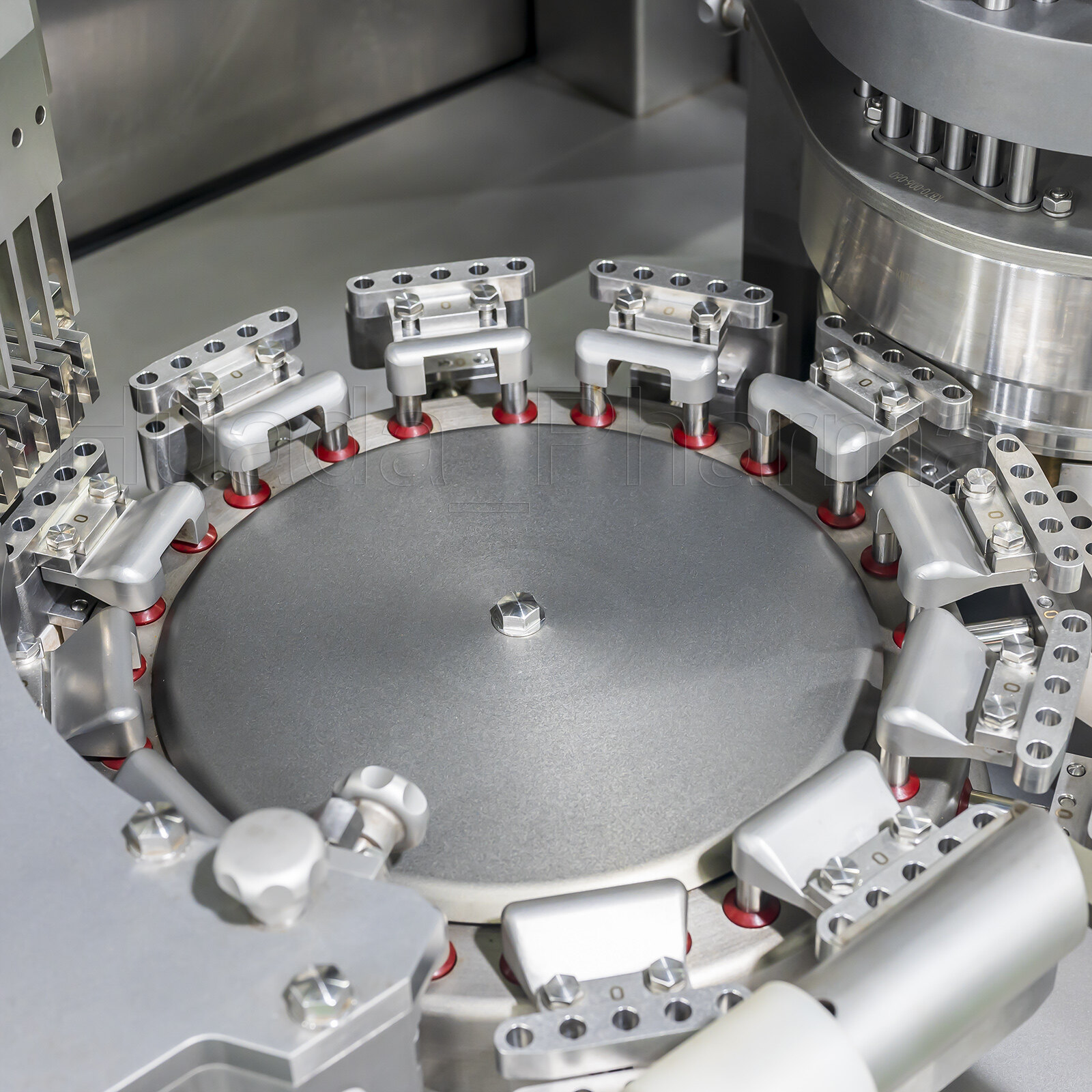

SFK-700 full automatic hard shell capsule filling machine adopts an international advanced design concept. Through the clearance operation, the full automatic hard capsule filling machine is completed by the pressure type of the high precision metering disc filling rod.

The design of the equipment parts is precise, the appearance is beautiful and practical, the operation is smooth, the mold can be replaced simply and quickly, and the capsule sorting ,Separating, filling, removing, locking, popping up, cleaning and many other processes can be completed automatically.

The equipment design is fully in line with the requirements of CGMP and FDA specification.

It is an intelligent device for pharmaceutical production, health care products and capsule production in food industry.

Introduction

The SFK-700 is designed to produce 42,000 capsules per hour.The device is suitable for low and medium batch production and frequent product changes.The equipment complies with GMP standards and can quickly complete mold conversion and implement equipment cleaning.

It is an intelligent device for pharmaceutical production, health care products and capsule production in food industry.

Advantage:

Main driver: SFK700 model adopts German Nord motor, SFK1500, SFK2500, SFK3000 adopts the German original imported Novexx Solutions motor, which has the advantages of stable output, long service life and low noise.

CAM Splitter: SFK700 model adopts Taiwan Te-shin cam splitter, SFK1500, SFK2500, and SFK3000 adopts the Japanese imported cam splitter, which has the advantages of high stability,the output torque, high rotary precision, long service life and low noise.

Electrical Components: the equipment adopts the international high quality electrical components, so that the service life of the electrical parts of the equipment is longer and more stable.

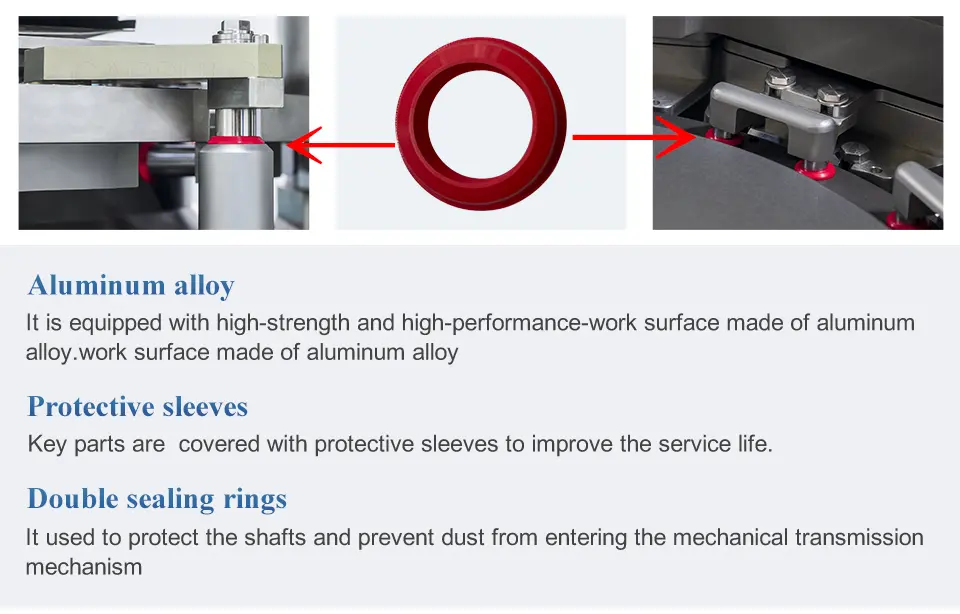

Energy Saving and Environmental Protection:The equipment adopts monolithic platen design, each movement part is sealed to avoid the powder penetrating into or out of the room as much as possible to ensure the cleanliness of the workshop. All the motors that the equipment adopted are with low energy consumption, which fully achieves energy saving;

System Configuration:The equipment adopts German SIEMENS system, SIEMENS inverter drive, stepless speed regulation, SIEMENS PLC program control, stable operation, safe and reliable.

Details Images

Feature

- The equipment adopts the international high quality electrical components, so that the service life of the electrical parts of the equipment is longer and more stable.

- The equipment adopts monolithic platen design, each movement part is sealed to avoid the powder penetrating into or out of the room as much as possible to ensure the cleanliness of the workshop. All the motors that the equipment adopted are with low energy consumption, which fully achieves energy saving.

- The equipment adopts German SIEMENS system, SIEMENS inverter drive, stepless speed regulation, SIEMENS PLC program control, stable operation, safe and reliable.

| Model | SFK-700 |

| Maximum fill | 42,000 granules /h |

| Number of filling holes | 5 holes |

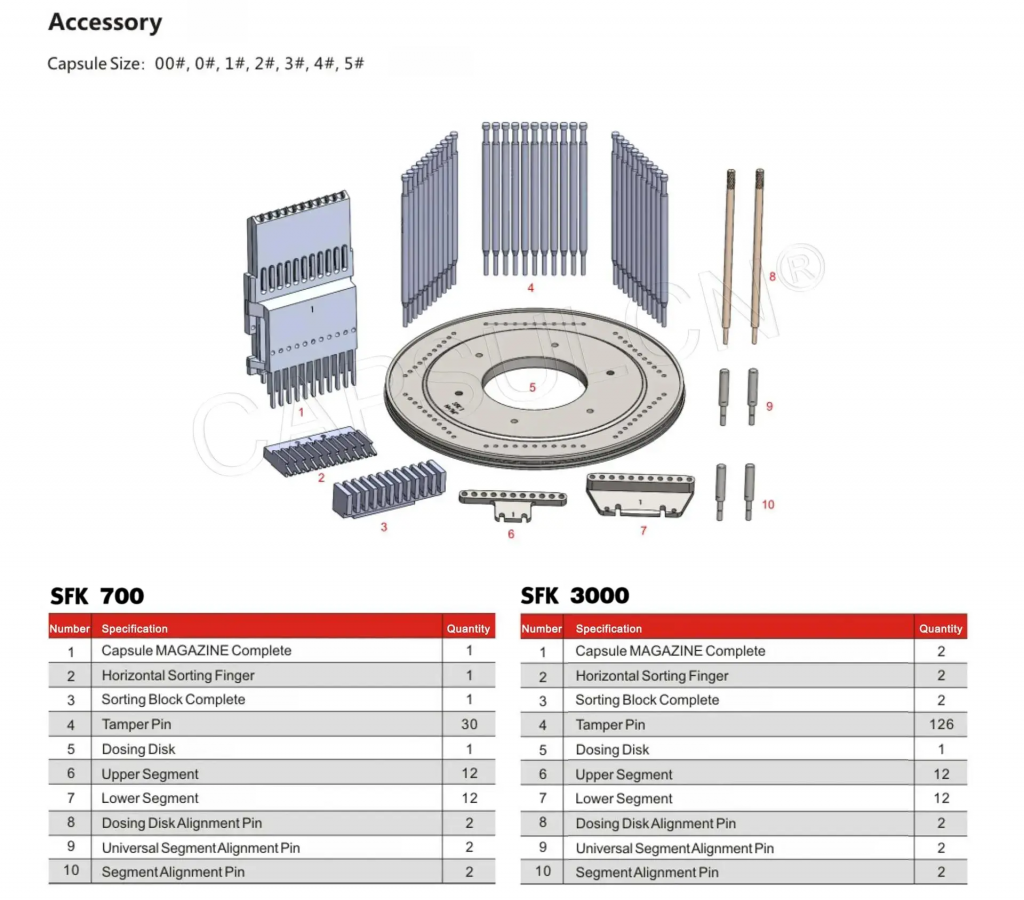

| Applicable capsule specifications | 00#-5# |

| Maximum power | 3KW |

| Machine connection load | 400V+/-10% 50/60HZ 3ph/pe 13A 9KVA |

| Vacuum connection load | 220V,550W |

| Vacuum cleaner connection load | 220V,1.5KW |

| Closed size | 951*1551*2155 mm |

| Unfold size | 2424*2240*2155 mm |

| Filling buffering procedure | ✔ |

| Buffering locking | ✔ |

| cGMP & FDA | ✔ |

| Quick cleaning | ✔ |

| Protruding mold | |

| Adjustable dosing disc | 🔘 |

✔: Yes 🔘: Optional

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China