As an industry that is engaged in the production of dietary supplements, functional foods, and herbal or natural products, capsules encompass an important part of your production. Every nutraceutical firm concentrates its resources on researching opportunities that enhance the manufacture of health-enhancing foods, and it is expedient that the tools required to make these discoveries functional are readily available.

Capsule fillers can mass produce encapsulated products in a shorter time, which help increase the profitability of your firm and allows these products to meet the demand of the growing consumer base.

With this guide, we hope to help you understand what a capsule filling machine is, the various types of fillers designed by our firms, how they can help increase production and revenue, and also where you can get the most suitable capsule fillers for your firm.

Capsule Filling Machine Definition

A capsule filling machine is a state-of-the-art equipment used by nutraceutical and pharmaceutical industries to fill empty capsules with various substances. These substances can be in the form of pellets, powder, granules, liquids, and a combination of liquid and solid ingredients.

They meet the needs of both large production lines producing countless capsules and small businesses focusing on small to medium volume medicines or dietary supplements. Regardless of the industry size, whether mega, mini, or micro, capsule filling machines are essential for production efficiency.

What Are Common Types of Capsule Fillers?

There are a variety of capsule filling machines existing in the world today. However, these machines can be categorized into three distinct models according to their functions. They include:

- Manual or Hand-operated Capsule Filler

- Semi-automatic Capsule Filler

- Automatic Capsule Filling Machine

The differences among the three types of capsule filling machines can be distinguished according to their functionalities, capacity, and mode of operation. The manual capsule filler is primarily hand-operated.

The semi-automatic capsule filler has both manual and automatic functional properties. While it is slightly hand-operated, this capsule filling machine can fill and rearrange capsules without relying on an operator.

The automatic capsule filling machine is largely independent of an operator. It majorly helps large-scale nutraceutical or pharmaceutical firms produce higher quantities of encapsulated products. The automatic capsule filler is also dynamic in operation, being able to effectively and efficiently fill powders, liquids, granules, and other tiny or fine substances into the capsule body.

How Does a Capsule Filling Machine Work?

As stated earlier, there are three primary types of capsule fillers, each with distinct components. Since these machines function differently, they will also have different working principles, but there is slight common ground in their encapsulating process.

However, we will be discussing the working principle of the automatic capsule filling machine, since it has the most complex structure and is majorly used by large and medium-sized pharmaceutical industries.

The capsule filling process using the automatic filler includes:

- Rectification (Orientation)

- Separation of Caps and Bodies

- Capsule Filling

- Capsule Locking and Ejection

Rectification or Orientation of Capsules

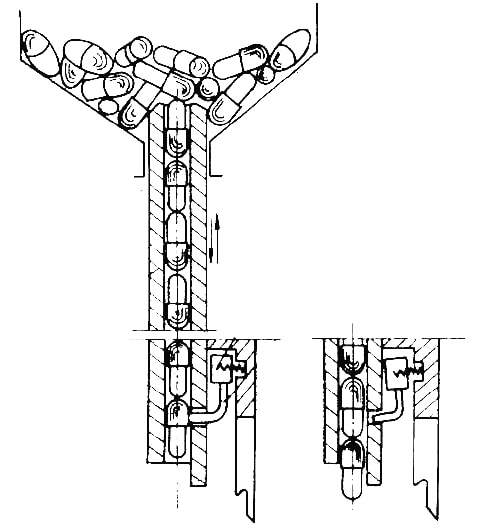

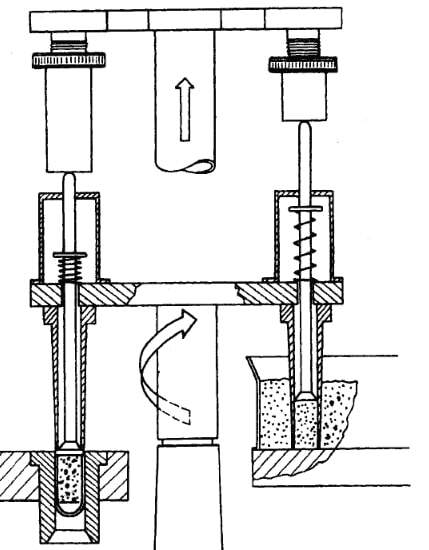

The rectification process involves pouring empty and enclosed capsules into the magazine containing two orientation fingers (horizontal and vertical fingers). The fingers are equipped with spring pieces to adequately adjust the capsules as they move the body downward in the segments.

During the operation, the capsule magazine moves up and down, ensuring that the capsules enter the holes and stick with the spring piece. As the capsules move downward, the spring piece releases it and allows it to fall.

Separation of Caps and Bodies

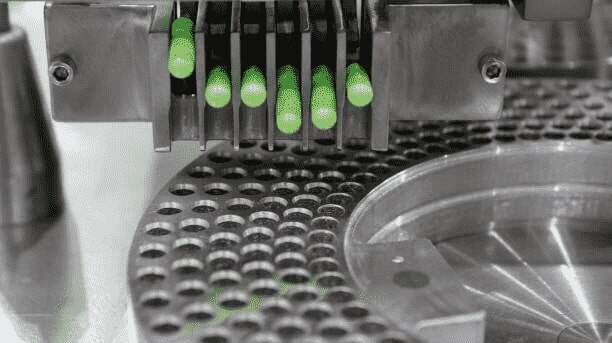

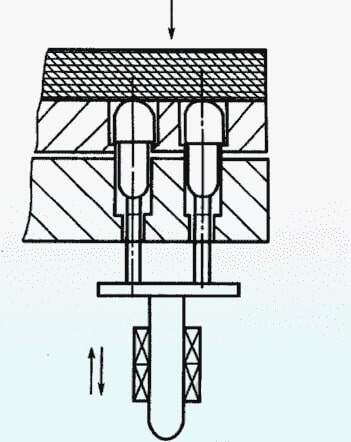

Once rectification is completed, the capsules are transferred from the segments to the separation station, where they will be separated by a vacuum divider. The vacuum divider moves upward towards the capsule tray, separating the body from the cap. The cap will remain with the capsule tray while the body will move downward to the filling segment of the machine.

Capsule Filling

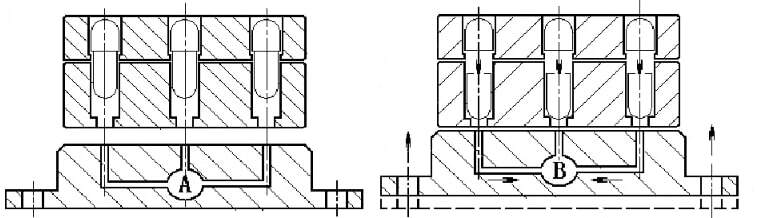

The capsule filling is the most important part of the whole working process of the filling machine. To fill a capsule after separation, there are two filling methods - the intermittent dosator filling and the tamping filling.

Intermittent Dosator Filling

This method of filling requires a single dosator and a small pin to fill the empty capsules. Here, the dosator will be plunged into the powder container. Once the powder enters the dosator’s cavity, the small pin will compress the powder into a slug, which is then injected into the capsule.

The intermittent dosator isn’t always an efficient method of capsule filling when compared with tamping filling. However, it is well-suitable for micro-dosing (a situation where capsules are filled with a small amount of powders).

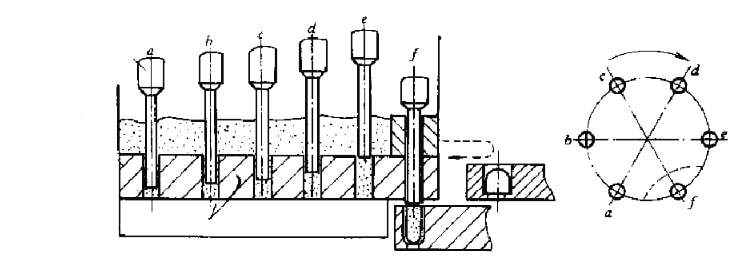

Tamping Filling

Tamping is commonly used in automatic filler machines due to its multi-holed dosing discs. As the powders flows into the holes, the tamping punch compresses the powder. This is done until the number of holes in the disc is filled. Afterward, the powder will be inserted into the capsule body with great precision.

Capsule Locking and Ejection

Once the filling process is completed, the upper and lower segments meet in the locking station, where the speed at which the segments move allows swift and accurate locking of the caps and bodies.

Lastly, the capsules are ejected into the outlet with the aid of the capsule ejection device. You will notice the capsules coming out and accompanied by compressed air. This helps the caps to be ejected easily without friction.

What Are the Advantages of Capsules Filling Machines?

The benefits of capsule filling machines cannot be over-emphasized. Irrespective of the type of filler you’re using, they can help you with production scalability, improved efficiency, quality, and enhanced revenue generation.

The advantages of capsule fillers include the following:

- They are designed to consume lower power without affecting the quality of output. So, alongside production efficiency, capsule filling machines aid in reducing the cost of certain utilities.

- They provide flexible and accurate functionalities for nutraceutical and pharmaceutical industries.

- capsule filling machines are fully GMB compliant.

- They help reduce the amount of normal loss of powdered substances to about 90%.

- Capsule fillers are designed to expediently fill machines at a high speed and also offer higher scalability.

- They can be used for Aseptic fill to weight.

Where to Buy Capsule Filling Machines?

If you are looking for where to purchase quality capsule filling machines that can help you scale your business, look no further than HUADAPharma. With core technology patents, HAUDAPharma has been designing and manufacturing capsule filling machines and other pharmaceutical equipment since 1992.

All of our capsule filling machines pass the most stringent quality tests and meet the highest standards in the industry. Over the years, our products have received more than 30 awards, attesting to our unwavering technicalities in providing excellent equipment that suits your industry demands.

To purchase our capsule filling machine, contact us and we will assign you a specific account manager who will be at your beck and call and also be responsible for your order.