Are you in the market for an automatic capsule filling machine? Whether you're new to the supplement industry or looking to streamline your manufacturing process, investing in the right equipment can often make all the difference. Yet, knowing where to start with so many options available on the market can be overwhelming.

Don't worry - we've got you covered! Here's a complete buying guide we put together to help you locate the perfect fit for your needs. From the different types of machines to the factors to consider, this guide will go over everything you need to know about choosing your automatic capsule filling machine. Let's dive right in!

Types Of Automatic Capsule Filling Machines

Automatic capsule filling machines can be divided into different types based on different criteria. Before you start shopping around, it's necessary to figure out the machine type for your specific needs.

Based on the type of formulation you're working with, there are two types of automatic capsule filling machines:

1. Powder Capsule Filling Machines

As the name suggests, this type of equipment is designed to fill capsules with dry formulations. These encapsulation machines use various mechanisms to perform filling operations. So, the powder capsule filling machines can be further divided into the following two types:

1) Dosator Capsule Filling Machine

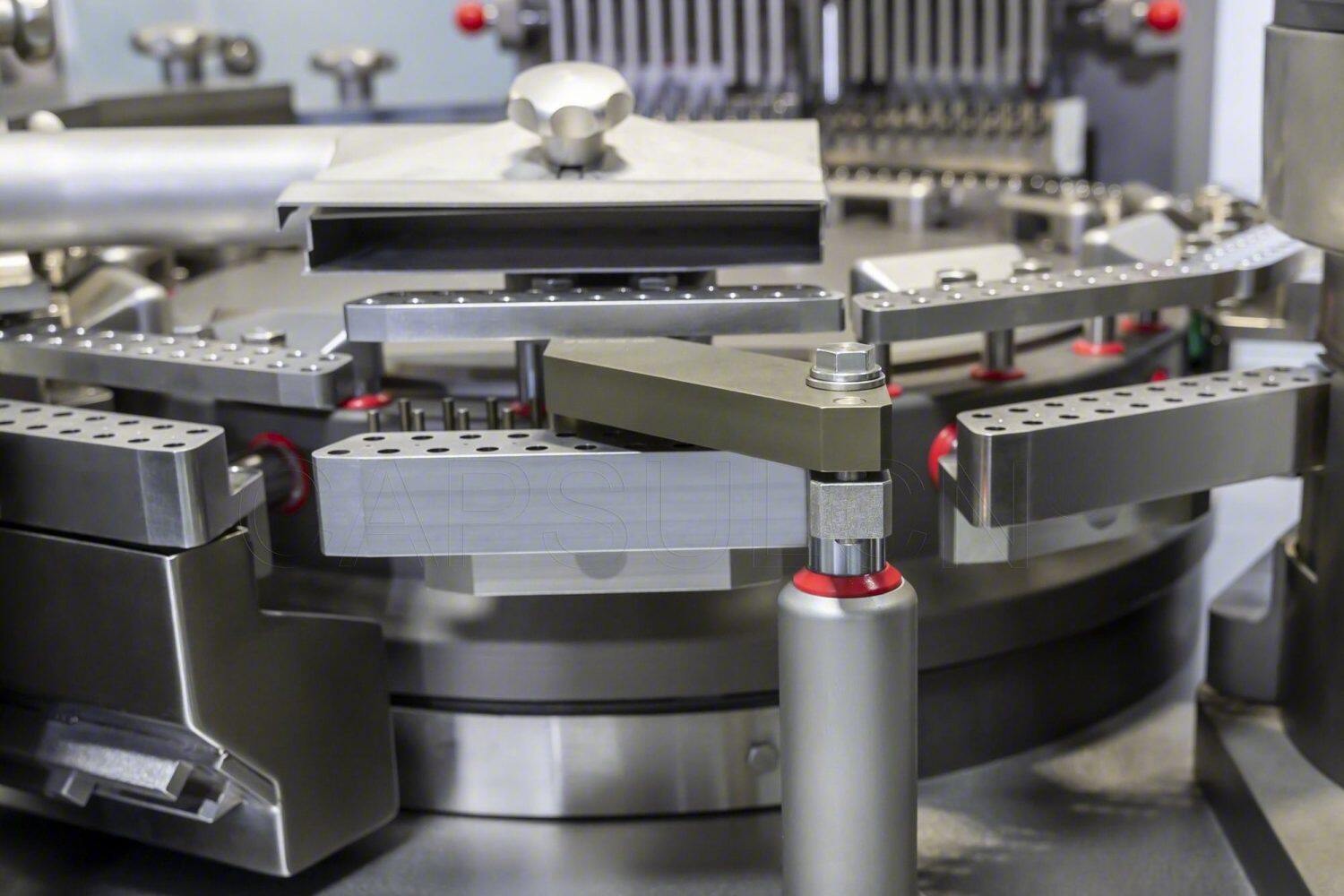

Dosator-based machines are designed to fill powder, pellet, or granular formulations into capsules. How do they work?

Their dosator system consists of a hollow tube and a piston. The mechanism uses a vacuum system to suck the powder and hold it in the tube. After that, the piston compresses the powder into a plug and then ejects it into an empty capsule body.

These machines are suitable for filling dry formulations that are free-flowing and do not have cohesive properties.

2) Tamping Pin Capsule Filling Machine

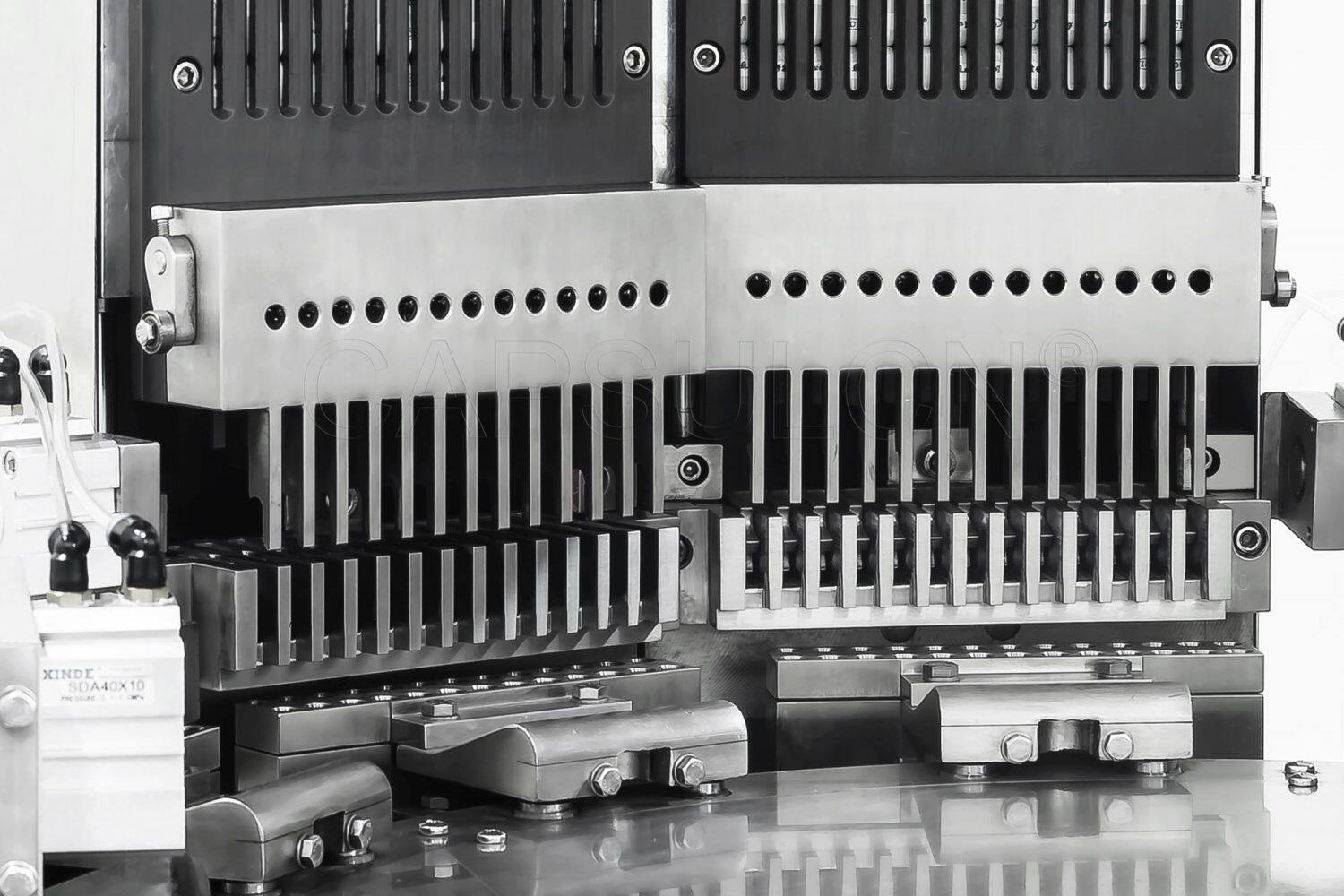

A tamping pin capsule filling machine is also known as a dosing disc capsule filling machine. It uses tamping pins and a dosing disc to produce uniform powder plugs. The tamping pin mechanism comprises five tamping stations and one transfer station.

During the process, the tamping pins compress the powder into plugs at the five tamping stations to reach the desired depth. And finally, at the transfer station, the dosing disc index the holes over empty capsule bodies. The powder plugs are ejected into the capsules.

These machines are suitable for filling dry cohesive powders that need to be packed tightly into capsules.

2. Liquid Capsule Filling Machines

These machines are designed to fill capsules with liquid or semi-liquid formulations. They use a different filling mechanism compared to the powder filling machines. Some examples of liquid capsule filling systems include the rotary pump, peristaltic pump, and piston pump systems.

3. Softgel Encapsulation Machines

A softgel encapsulation machine is specialized pharmaceutical equipment. The machine employs a rotary die process to produce softgel capsules. It can produce capsules with a longer shelf life than other encapsulation methods. Softgel encapsulation machines are suitable for manufacturing products in various industries, such as pharmaceuticals, nutraceuticals, cosmetics, and food.

Questions To Ask When Choosing Your Automatic Capsule Filling Machine

Buying an automatic capsule filling machine is a major investment and a long-term commitment. Before you sign the paperwork, it's important to ask the manufacturer all the necessary questions.

Learning as much as possible about the machine's features will help you make the most informed decision. Here are some of the questions you might want to ask the supplier.

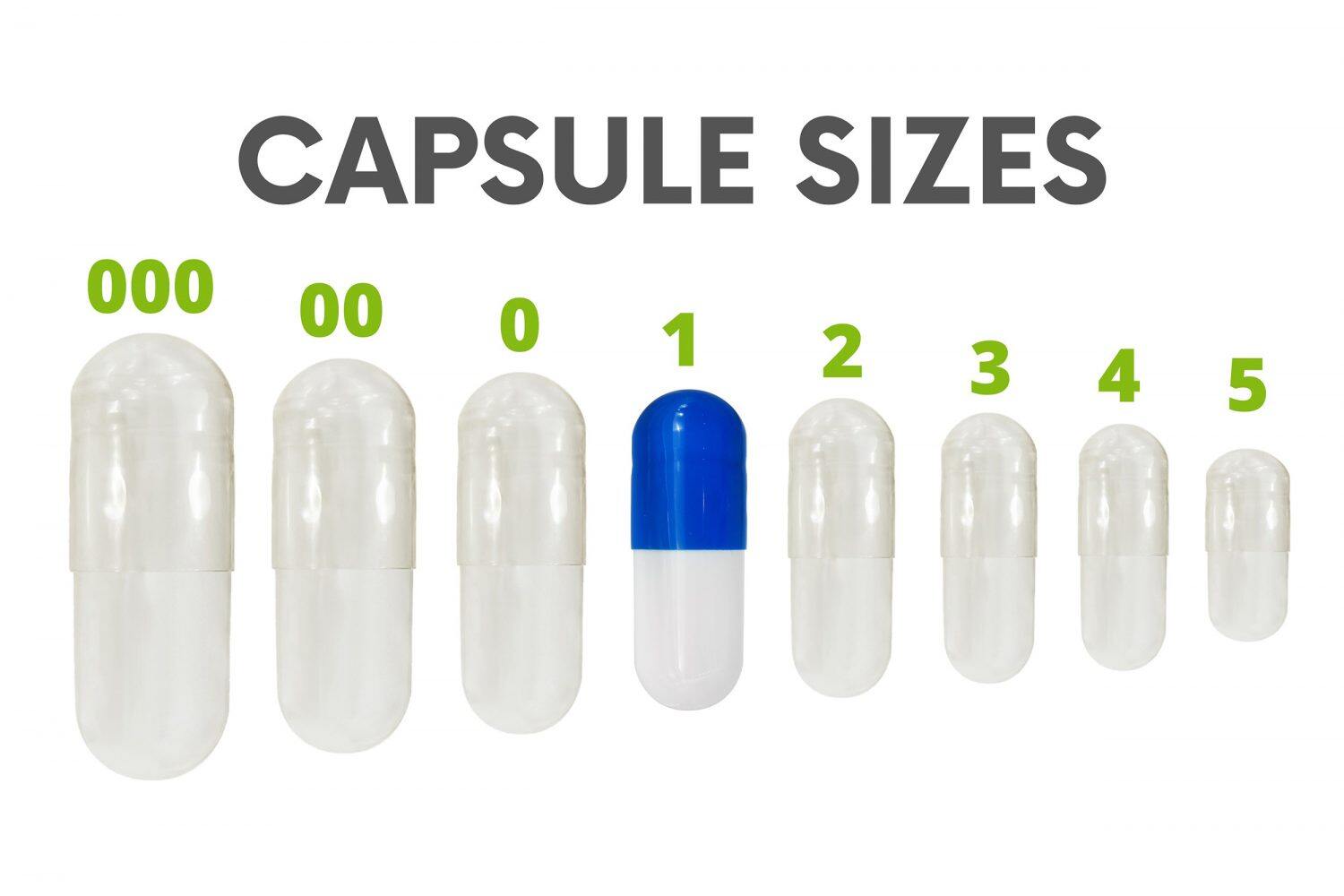

1. What types and sizes of capsules can this machine handle? Capsules come in a variety of types and sizes. This means some machines may not be able to handle the capsules you intend to fill. So make sure the machine you choose is compatible with the capsules you will be using.

2. What types of filling materials can this machine handle? Some machines may cause clogging when handling certain materials. Look for a machine compatible with the materials you will use to fill the capsules, such as powders, granules, or pellets.

3. How many capsules can this machine fill in an hour? This is about the production capacity. The maximum capacity of capsule filling machines is one of the most significant features to consider. Make sure you choose a machine with a capacity based on your production needs.

4. What is the accuracy rate for filling capsules with this machine? A good capsule filling machine should be able to fill capsules accurately and consistently. This will help achieve the desired dosage level for each capsule and ensure minimal wastage.

5. How easy is it to operate this machine? An automatic capsule filling machine should be easy to set up and operate. Make sure the machine comes with a user-friendly HMI. This allows you to set up the filling process parameters easily to ensure the quality of the final product.

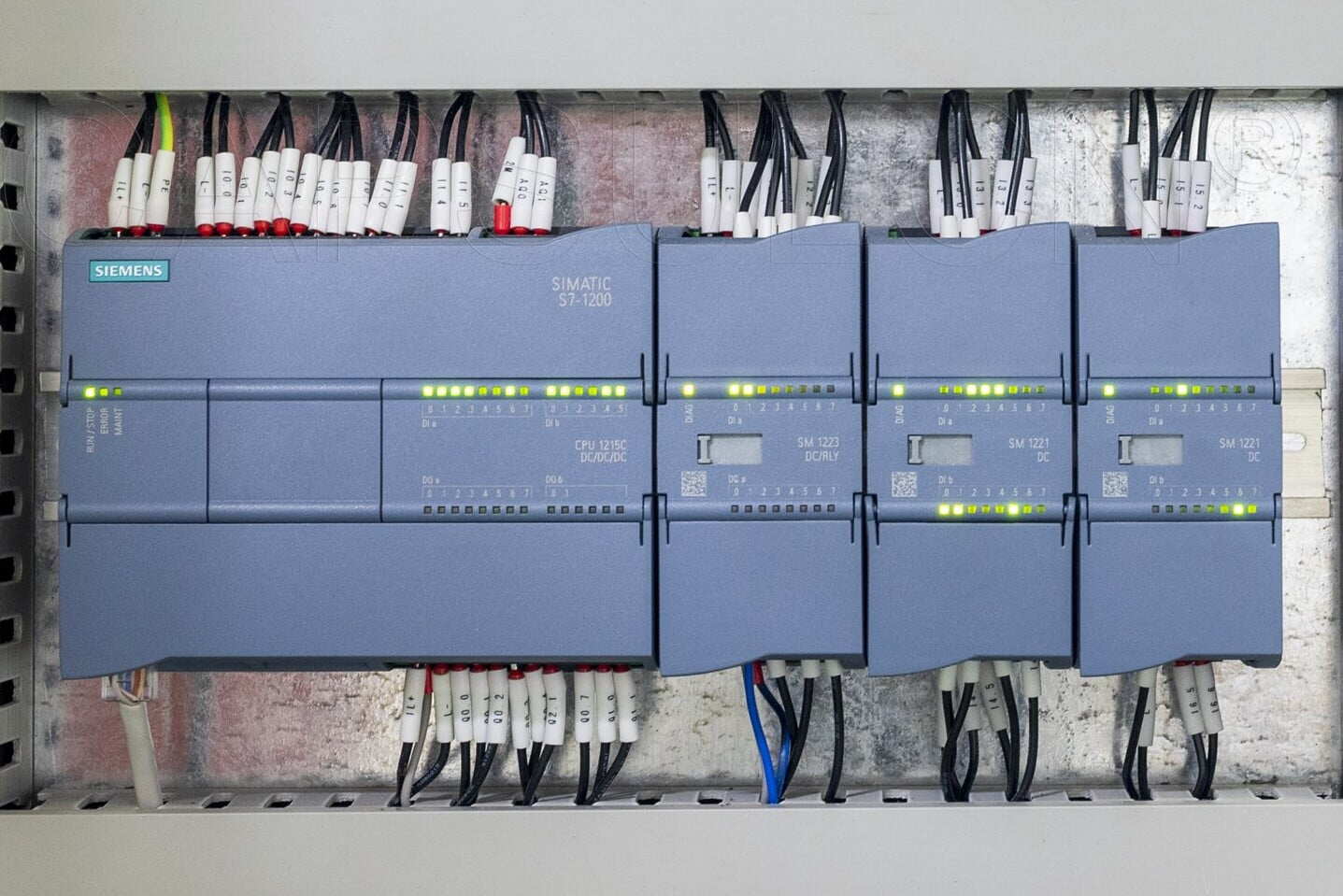

6. What type of control system does this machine use? The machine's control system can affect its ease of use and accuracy. Look for a machine with a reliable, PLC-based control system that allows you to adjust settings and monitor production easily. You can also ask the manufacturer if they have any software or tools for optimizing the production process.

7. Is this machine customizable to fit specific needs? Some machines can be customized to meet specific production needs. You may be able to add additional modules or change the machine's configuration to handle different capsule formulations. Or you may want it to integrate with other equipment or your product line for a more streamlined production process.

8. What kind of customer service and technical support is provided with the machine? When choosing a machine, ensure it has reliable maintenance and repair services. This helps minimize downtime and ensure efficient operation. Look for a manufacturer that offers good technical support and after-sales service. Training and support are also essential, especially if you're new to capsule filling.

9. How does the cost of this machine compare to other similar machines on the market? The cost of a machine may include the initial investment and other expected operating costs. So you should shop around and ensure the machine that fits your budget.

10. What specific validation requirements does this machine meet? If you are working in a regulated industry, such as pharmaceuticals, you may need a machine that is CE-marked or has a GMP or cGMP certification.

11. What is the warranty period for this machine? Ask the supplier about the warranty that comes with the machine. Check whether it provides adequate coverage for your needs. You might also want to consider purchasing an extended warranty to provide extra protection.

Final Word

Purchasing an automatic capsule filling machine is not an easy job. By asking the right questions and doing your research, you can find the perfect machine that provides reliable, high-quality results for years to come. We hope this ultimate guide has provided valuable insights to help you make an informed decision.