If you're in the syrup business, whether it's maple syrup, cough syrup, or any sticky concoction, you know how messy and time-consuming manual filling can be.

This is where an automatic syrup filling machine steps in as a game-changer. This machine can take the hassle out of bottling syrup by automating the process. With it, you will have each bottle filled accurately and efficiently.

In this guide, we'll walk you through everything you need to know about automatic syrup filling machines. By the end, you'll be ready to start out or level up your syrup production with confidence!

What Is an Automatic Syrup Filling Machine?

An automatic syrup filling machine is a specialized liquid packaging machine. It's designed to dispense syrup into bottles with minimal human labor.

In simple terms, it's an automated bottling system that measures a precise amount of syrup and fills it into each bottle, all in a fast, consistent flow. These machines are built to tackle the unique challenges of syrup—a liquid that's often thick, sticky, and prone to making a mess.

Key features of an automatic syrup filling machine:

- Multiple filling nozzles;

- Pumps or pistons for measuring syrup; and

- A conveyor system to move bottles in and out of the filling station.

Most syrup filling machines are made of food-grade stainless steel for hygiene. They can be integrated with capping and labeling equipment to form a complete syrup packaging line.

Common Applications in Food, Beverage, and Pharma

Automatic syrup filling machines are used across a range of industries wherever thick liquids need bottling. Some common applications include:

- Food & Beverage Industry: It's perhaps the most obvious use. These machines bottle table syrups like maple syrup, chocolate syrup, corn syrup, honey, fruit concentrates, and flavored syrups for coffee or sodas. An automated filler ensures each bottle gets the exact same amount without drips or overflow. For example, honey and dessert syrups are often filled with piston fillers to handle their thickness.

- Pharmaceutical Industry: Automatic syrup fillers play a huge role in pharma production lines. They are commonly used to fill cough syrups, medicinal syrups, liquid vitamins, and tonics into bottles. Pharmaceutical syrups require precise dosing and hygienic processing. These tasks are ones that automated machines excel at. By using various filling technologies, cough syrup bottles can be filled accurately and quickly while keeping the product sterile and uncontaminated. Many pharma-grade machines also support quick cleaning and changeover.

- Cosmetics & Personal Care: Think beyond the word "syrup". Any thick liquid that flows can potentially be filled by these machines. In cosmetics, products like shampoo, liquid soaps, shower gels, or lotions have a syrupy consistency and can be bottled using syrup filling equipment. For instance, facial gels, creams, or oils can be filled using piston or pump-based syrup fillers just as easily as edible syrups.

- Chemical & Other Industries: Agricultural chemicals (like certain fertilizers, pesticides, or herbicides) and automotive fluids (thick oils or additives) can also be bottled by machines similar to syrup fillers. In these cases, the filler handles viscous or foamy liquids, delivering accurate fills. While the product isn't "syrup" for eating, the filling principles remain the same. This versatility means an automatic syrup filling machine can often be adapted to fill a variety of liquids in different industries, making it a flexible investment.

Types of Automatic Syrup Filling Machines

Not all syrup fillers work the same way. In fact, there are several types of filling technologies used to handle different product characteristics and production needs. Below, we break down the most common types—including how they work—so you can understand which might be the best fit for your syrup product.

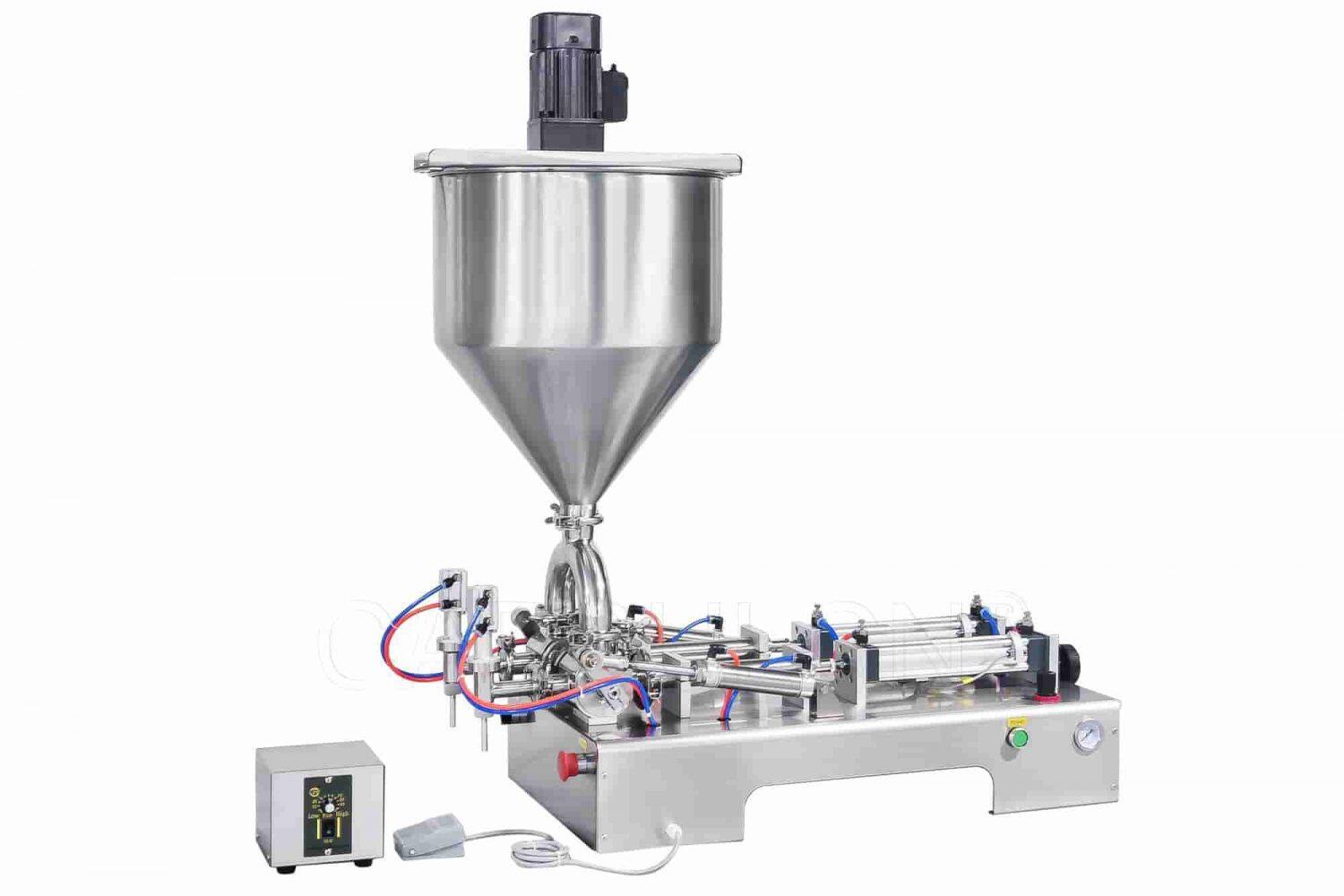

1. Piston Filling Machines

Piston fillers are a popular choice for thick liquids like syrup. They use a simple volumetric principle: a piston and cylinder mechanism draws in a set volume of product and then pushes it out into the bottle.

How it works:

- The piston retracts, creating a vacuum in the cylinder. This vacuum draws syrup from a hopper or tank through a one-way valve into the cylinder.

- Once the cylinder is filled with the desired volume, the inlet valve closes. The machine now has exactly, for example, 500 ml of syrup inside the cylinder.

- The piston then moves forward, forcing the syrup out through the nozzle into the waiting bottle. A second valve opens to direct the flow to the nozzle during this stroke.

- Many piston fillers have nozzles with anti-drip features. As the piston completes the fill, the nozzles shut off to prevent any trailing drops of syrup from making a mess.

Because piston fillers physically push out a set volume, they are ideal for products sold by volume. They also handle very thick syrups with ease. Many automatic syrup filling machines use piston technology for this reason. Piston fillers can be found in both semi-automatic benchtop models and fully automated multi-head systems.

2. Gravity Filling Machines

Gravity fillers are one of the simplest types of liquid filling machines. They rely on gravity to fill containers. These are typically used for low to medium-viscosity liquids, so they can work for syrup products like beverage syrups or light maple syrup.

How it works:

- Bottles are positioned under the filling nozzles, either by hand in semi-auto setups or via a conveyor in automatic systems.

- Valves or nozzles open for a preset amount of time to allow syrup to flow into the bottles. Because the flow rate can be consistent for a given liquid, controlling the time of flow results in dispensing a consistent volume—this makes it a time-based volumetric filler.

- Once the time elapses, the valves close. Typically, the amount of syrup each bottle gets is very close, assuming the syrup's viscosity and the head pressure from the tank remain constant.

Gravity fillers typically have fewer moving parts and are easy to clean. They work best with non-foaming, free-flowing liquids. They are often the most cost-effective option for filling machines, great for companies on a tight budget who still want automatic filling.

3. Overflow Filling Machines

Overflow fillers are commonly used in industries like beverages and sauces. They can be useful for syrups as well. An overflow filler ensures that every bottle is filled to the same visual level.

How it works:

- Bottles are sealed against special overflow nozzles that dive into the bottle necks. The syrup is pumped through these nozzles.

- As each bottle fills, the liquid reaches the tip of the nozzle. The nozzle has an overflow port. Once liquid hits that level, any extra syrup flows back through the nozzle into a return line and overflows back to the reservoir or tank.

This method guarantees uniform fill height. So, many bottlers of thin syrups use overflow fillers to get that perfect fill line every time. Plus, the overflowed syrup isn't wasted. It goes back to the tank for reuse, so product waste is minimal.

4. Pump Filling Machines

Pump fillers use various pumping mechanisms to move syrup from a supply tank into the bottles. These can range from gear pumps, lobe pumps, and diaphragm pumps to peristaltic pumps. Pump-based filling machines are very versatile. They can handle both thin liquids and fairly thick syrups.

A special subtype worth mentioning is the peristaltic pump filler, commonly used in pharmaceutical and high-purity applications. The syrup is contained in a silicone or food-grade tube looped through a pump head. The big advantage is that the product only contacts the inside of the tubing, making it super hygienic and easy to clean—you can just replace the tubing if needed.

How it works (Peristaltic Pump Filler example):

- As the pump motor turns, rollers compress the flexible tube and push the syrup forward in pulses.

- The amount dispensed is controlled by how long the pump runs. This gives a precise volumetric control because each rotation moves a known volume.

Pump fillers are great for small dose fillings (like 10 ml bottles of syrup or medicinal drops) and for products where hygiene is paramount. Outside of pharma, pump fillers are used for everything from perfumes to essential oils and yes, syrups too. They might be a bit slower for very thick syrups than piston fillers, but they are flexible. For example, you could program one machine to fill 100 ml bottles one day and 500 ml bottles the next, just by changing the pump settings.

5. Net Weight Filling Machines

A net weight filler is a bit different from the above types: it measures weight rather than volume. These machines have scales integrated into their filling stations. They dispense syrup into a container until the scale reads the target weight, then stop. Net weight filling is especially useful when dealing with very large container sizes.

How it works:

- Each bottle or jug sits on a scale (load cell). The machine's controller knows the target weight (for example, 5.00 kg of syrup).

- The filler uses gravity, pump, or other method to dispense the syrup into the container.

- The scale continuously monitors how much weight has been added. As it approaches the target, the machine might slow the flow to top off accurately.

- Once the exact weight is reached, the flow shuts off.

Net weight fillers are common for bulk syrup packaging (like filling gallon jugs of syrup or big industrial totes). They ensure every container has virtually the same weight of product inside. These machines are often a bit slower than volumetric fillers, but they excel in accuracy. Many net weight fillers can handle large volumes. Some can fill containers from small bottles up to 5-gallon (20 L) jugs on the same machine.

Benefits of Using an Automatic Syrup Filling Machine

Why invest in an automatic syrup filling machine? There are plenty of advantages that these machines bring to syrup producers big and small:

- Faster Filling Speeds: Much faster than filling bottles by hand. For example, filling 500 bottles manually can take hours, but a machine can do it in just minutes. Some machines can even fill up to 200 bottles every minute.

- Accurate Filling Every Time: Fill each bottle with exactly the right amount of syrup every time. For example, piston or pump fillers can fill bottles accurately within just a few milliliters. This means no wasted syrup or uneven bottles.

- Less Waste, More Savings: Reduce spills and overflow. Many have drip-free nozzles to avoid waste. This is especially helpful if your syrup is expensive, like in medicines. Plus, fewer spills mean your workspace stays clean and safe.

- Lower Labor Costs: Cut down on the number of workers you need. For example, you might need only one worker instead of five, letting your staff do other important jobs.

- Better Hygiene and Safety: Limit human contact with the syrup, reducing contamination risks. The syrup goes directly from sealed tanks into bottles through clean tubes. For example, machines used in food or medicine often work in sterile rooms and are easy to clean, keeping your products safe.

- Easy to Grow and Add Equipment: Easy to expand as your business grows. You can start with a basic machine and later add more equipment, like cappers or labelers. Some models allow you to add more nozzles to fill bottles faster.

- Professional Quality Packaging: Fill bottles neatly and consistently. Professional packaging improves your brand's image and helps attract more customers.

How to Choose the Right Automatic Syrup Filling Machine

If you're convinced you need a syrup filler, the next step is choosing the right machine that fits your business. The "best" choice depends on your specific operations, product, and goals. Here are some tips for small, medium, and large businesses when selecting an automatic syrup filling machine:

- Small Business / Startup

If you're just getting started or working with lower production volumes, a semi-automatic syrup filling machine is a great way to dip your toes into automation.

Why it works for small businesses:

- Some basic models start at under $1,000, though expect to spend a few thousand for decent quality.

- It has a less complex structure and is easy to operate.

- Machines like benchtop piston fillers or gear pump fillers can easily handle thick syrups.

- Many semi-auto systems can be expanded or integrated with more automation later on.

Real-world example:

- Small maple syrup producers often start with a benchtop piston filler that costs under $5,000, which already saves tons of time compared to filling bottles by hand.

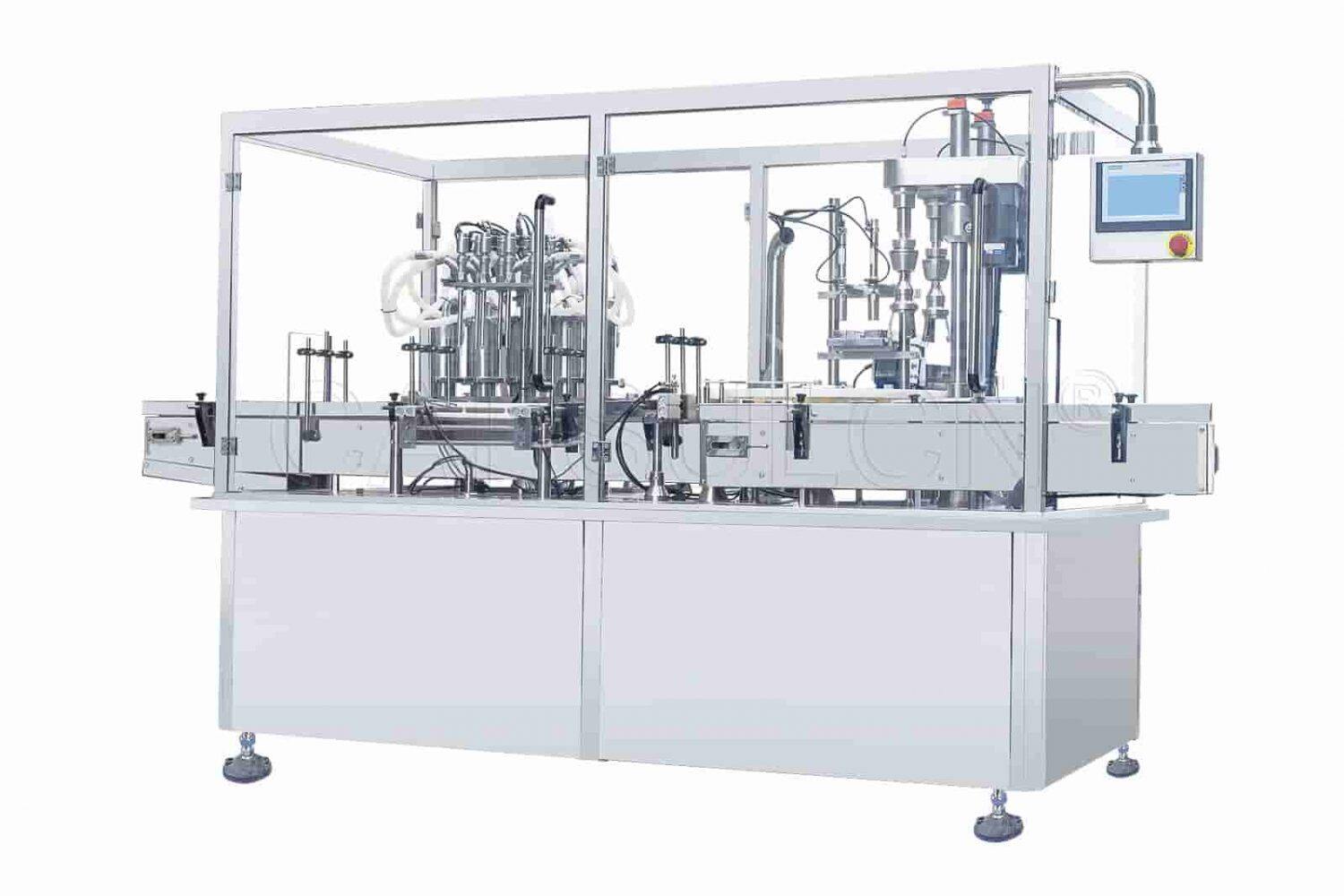

- Medium-Sized Business

Once your orders start increasing, you'll want to step up to a fully automatic syrup bottle filling machine. This helps streamline your process and cut down on labor.

Ideal features for growing businesses:

- 4 to 8 filling heads for moderate speed (30–60 bottles per minute).

- Comes with a conveyor system and PLC controls for ease of use.

- Can be paired with automatic capping machines and labelers.

- Suitable for multiple product types – handy if you fill syrup, sauces, or oils.

Price range:

- Expect to invest $10,000 to $30,000, depending on the brand, features, and level of automation.

- Large Enterprise / High-Volume Producers

If you're supplying supermarkets or exporting products, you'll need a machine that can handle serious volume.

What to look for:

- Rotary filling machines or high-speed inline systems with 10–16 filling heads.

- Integrated packaging lines, including bottle unscramblers, cappers, conveyors, and labelers.

- Servo-driven fillers for maximum accuracy at high speeds.

- Smart features, including auto-cleaning cycles, remote diagnostics, and recipe memory.

Price range:

- These high-end machines typically cost from tens of thousands up to six figures, especially when custom-engineered.

BUYING TIPS:

No matter the size of your business, always work closely with a trusted manufacturer. Ask for performance guarantees (like fill accuracy and throughput rates) in your contract. You want a system that works seamlessly with your entire packaging line.

Automatic Syrup Filling Machine Maintenance Tips

Once your automatic syrup filling machine is set up and running, keeping it well-maintained is crucial for its efficiency and longevity. Here are some essential maintenance tips:

- Warm Water Rinses: Use warm water regularly to dissolve any sticky syrup residue. Warm water easily clears out sugar deposits and prevents clogs.

- Check for Sugar Crystals: Sugar crystals can form inside nozzles and hoses. Regularly check these areas for crystal buildup and clean thoroughly.

- Inspect Syrup Valves Often: Valves handling syrup can get sticky quickly. Inspect and clean them more frequently than standard filling machines to keep them working smoothly.

- Special Attention to Seals: Syrup filling machines use seals that can quickly wear due to syrup's sticky nature. Regularly inspect seals and replace any showing wear or cracks early.

- Drip-free Nozzle Maintenance: Drip-free nozzles can clog faster with syrup. Regularly check, clean, and ensure they're working properly to avoid messy drips.

- Use Food-Grade Lubricants: Always use food-grade lubricants specifically recommended for syrup filling machines. This prevents contamination and ensures smooth operation.

- Temperature Monitoring: Syrup viscosity can change with temperature, affecting filling accuracy. Regularly check and adjust machine settings based on syrup temperature.

- Keep Spare Parts Handy: Syrup is hard on machine parts, so keep extra seals, hoses, and nozzles in stock. Quick replacements help avoid downtime and keep production flowing smoothly.

Final Word

Ready to take the next step? If you're considering investing in an automatic syrup filling machine, don't go it alone. It's always helpful to reach out for a consultation with packaging machinery experts or suppliers.

At Huada Pharma, we offer personalized recommendations and cost estimates. We can also arrange demonstrations of various models. If you have any questions or need guidance on the best options, feel free to contact us!