The safety of empty gelatin capsules is important for both manufacturers and customers. For manufacturers, it directly impacts how good the product is, if it follows the rules, and if people trust their brand. For consumers, they depend on these capsules to stay healthy. They believe the capsules they take won’t harm them and are clean.

This article will help you understand more about the safety of empty gelatin capsules. Then you’ll know how to make them more carefully.

What are empty gelatin capsules?

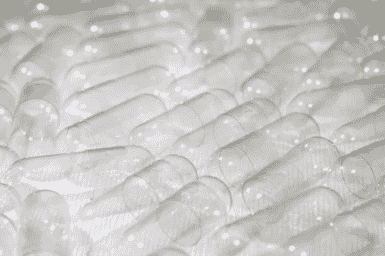

Empty gelatin capsules can hold medicines in different forms, like powders, liquids, semi-solids, etc. And gelatin is a clear, colorless, and almost tasteless material. It comes from a protein called collagen. This could be found in the skin, bones, and tissues of animals like cows, and pigs. Gelatin is a perfect materials for making capsules. Because it can dissolve quickly in the stomach and allows the medicine be released efficiently.

Gelatin capsules are always made of water and plasticizers, such as glycerin or sorbitol. This makes the capsule more flexible and easy to swallow. Empty gelatin capsules are commonly used in making medicines and supplements.

Types of capsules

There are two kinds of capsules: hard and soft gelatin capsules. Each kind has its own special features. It makes them good for different uses.

Hard capsules

Hard gelatin capsules consist of two parts, a body and a cap. They are like puzzle pieces that fit together to hold the stuff inside. These capsules can be filled with dry things like powders, granules, or pellets. To make hard capsules, the body and cap are made one at a time and then put together when filling. The filling process can be done by manual, semi-automatic, or fully automatic filling machines. It mainly depends on a production scale.

Hard gelatin capsules are commonly used for prescription medications, over-the-counter drugs, and dietary supplements. They are particularly well-suited for encapsulating powders and granulated substances.

Soft capsules

Soft gelatin capsules are also known as softgels. They are one-piece capsules that are formed, filled, and sealed in a single operation. These capsules are typically more flexible than hard gelatin capsules. Because they require a higher concentration of plasticizers in the gelatin.

Softgels are produced by rotary die encapsulation. In this way, the gelatin is continuously formed into the capsule shape. It can be filled with a liquid or oil, and sealed. If you want to make capsules with fish oil, and liquid herbal extracts, softgels are a good choice.

How are gelatin capsules made?

Pre-treatment of raw materials

Raw materials should be processed to prepare for gelatin extraction. Bones, skin, and connective tissues should be thoroughly cleaned and treated with acids or alkalis. It helps break down the collagen and remove impurities. For example, bovine and porcine gelatin require to condition of hides with lime. In the case of fish gelatin, the process is often milder, given the more delicate nature of the raw material.

Gelatin extraction

After pre-treatment, the collagen is extracted through hydrolysis. In this way, the treated raw materials are subjected to hot water or steam. The heat breaks down the collagen into gelatin. Then it dissolves in water, forming a viscous solution. The extraction process needs carefully controlled to achieve the desired quality of the gelatin, such as its bloom strength and viscosity.

Filtration and purification

The gelatin solution is then filtered to remove any remaining impurities, including fat, minerals, and other unwanted particles. This step is critical to ensure the purity of the gelatin and prevent contamination. In addition, the solution may undergo additional purification steps, such as deionization, to further enhance its quality.

Concentration and drying

Once purified, the gelatin solution is concentrated through evaporation, increasing its gelatin content. The concentrated solution is then cooled and dried, usually in a vacuum drier. It helps produce a gelatin film or powder. The drying process is carefully controlled to prevent the formation of any microbial contamination. This ensures the safety of the final product.

Capsule formation

The dried gelatin is then mixed with water and plasticizers to create a malleable material. The mixture is heated to form a homogeneous solution, which is then fed into a capsule-making machine.

For hard gelatin capsules, the solution is molded into a body and a cap by using stainless steel pins. The gelatin is allowed to cool and solidify around the pins, forming the capsule shells. In the case of soft gelatin capsules, the solution is used to form and seal the capsules around the fill material in a continuous process.

Drying and hardening

After formation, the capsules are dried to remove excess moisture and achieve the desired hardness. This step is essential to ensure the capsules maintain their shape and integrity during storage and use.

Quality control

Strict quality control measures are implemented to ensure that the capsules meet safety and quality standards. Empty capsules should be tested, like checking the physical properties of the capsules, to ensure safety. And they should also meet regulatory requirements.

In the US, your capsules should comply with FDA regulations. It regulates that gelatin manufacturers must comply with GMPs. GMPs outline the standards for cleanliness, quality control, and safety in the manufacturing process. The FDA also requires that gelatin capsules used in pharmaceuticals and dietary supplements be tested for safety.

In EU, the European Pharmacopoeia sets similar standards for gelatin used in pharma products. These standards specify the acceptable levels of contaminants, as well as the physical and chemical properties that gelatin must meet to be considered safe.

Two common concerns about empty gelatin capsules

When using empty capsules, you must know the following factors to ensure your customers don’t have side effects when consuming the capsules.

Allergies

One of the primary concerns with gelatin capsules is the potential for allergic reactions. It is particularly important for individuals who have allergies to specific animal products such as cows and pigs. They may be at risk if they consume gelatin capsules. So it is key for manufacturers to clearly label the source of gelatin used in their capsules. This can help consumers make informed choices.

Vegetarian considerations

Since gelatin is derived from animal collagen, it is not suitable for those who follow a vegetarian or vegan lifestyle. If most of your customers are vegans, you’d better make vegetarian capsules. They are plant-based capsules mainly made of HPMC, pullulan, etc.

The end

Now you may have a better understanding of whether empty gelatin capsules are safe or not. Actually, with the right knowledge and careful sourcing, gelatin capsules are indeed a safe and effective option for your business. However, you should note your customers’ allergies and dietary restrictions. It not only protects your customers but also builds trust and loyalty with safe and well-chosen capsules.