Accurate and efficient tablet counting is crucial in many manufacturing industries, such as pharmaceutical and food. Automatic tablet counting machines have become increasingly popular. It offers high speed, precision, and reliability that manual methods can’t match. This machine is suitable for small packaged goods and integrating into a production line. To help you get a better understanding of this machine, we’ll explore

- What is an automatic tablet counting machine?

- What key parts should you know in this machine?

- How to choose one suitable for your business?

- How to troubleshoot an automatic pill counter?

What is an automatic tablet counting equipment?

This machine is used to count tablets and capsules quickly and accurately into bottles. It is equipped with advanced sensors to count products as they pass through the machine. It can detect each item and record the total. This ensures each container has the correct number of products. Moreover, this equipment can also detect damaged or broken tablets. These tablets would be picked out. The process is fully automated, so operators do not need to count by hand. You can check the video to see it clearly.

Automatic tablet counters feature high efficiency and consistency. So many tablet manufacturers integrate it into other machines like capsule filling machines to improve production.

Six key functional parts of an automatic tablet counter

A highly efficient machine depends on every part to work well. Here lists several important parts you should know.

Hopper

Hopper is a container located at the top of the machine. It can hold pills before counting begins. There is usually a flap at the bottom of the hopper. Operators can adjust this flap to control the flow of pills. Most hoppers are made of stainless steel or food-grade plastic. These materials ensure hygiene and prevent contamination.

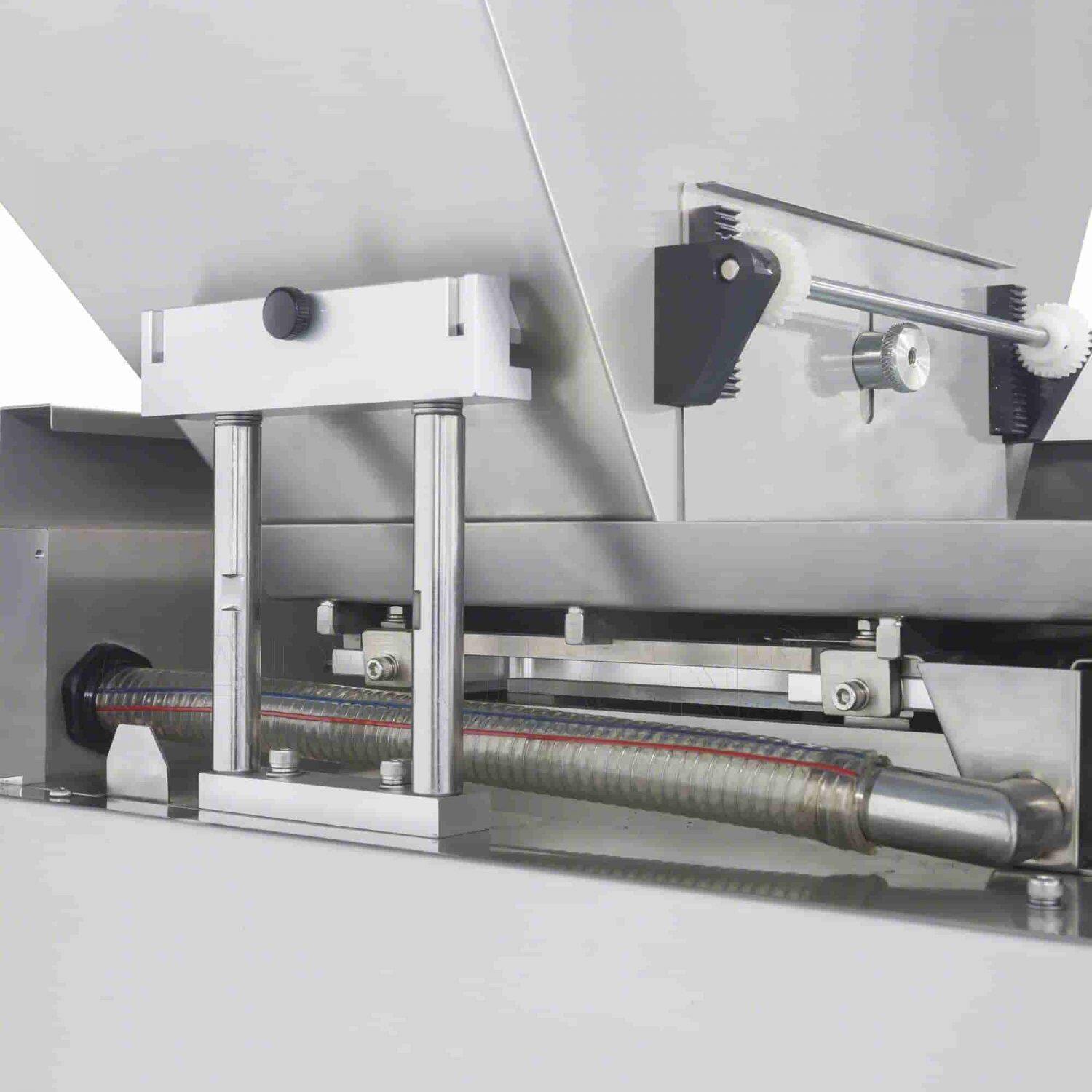

Vibrating system

Most automatic pill counters use a three-stage vibrating design. The discharge channel has 8 pathways. The plates in the discharge channels are usually corrugated vibration plates. They are fixed to a vibration support. During operation, the vibrating component pulls the support, causing the plates to vibrate and pill flowing. The vibration speed shows on the display screen. It can be adjusted to change the pill flow rate.

Dust removal system

Each channel on the front of the material discharge plate has a row of small holes. When the machine is working, the material moves and dust falls through the holes into the dust box below. In addition, the machine is equipped with a dust cover. It is always made of transparent acrylic. This cover not only prevents dust during operation but also allows you to clearly see the discharge process.

Counting and filling mechanism

This structure mainly consists of a material feeding tube, a high-sensitive counting sensor, and a funnel. Pills flow through the material feeding tube and pass through the sensor. It generates a photoelectric signal to detect the amount of material. The counting result is displayed on the interface in real-time. Then, the material passes through the nozzle to be filled into the bottles. Please note that the funnel opening should align with the bottle opening for accurate filling. In addition, the size and shape of the funnel can be customized based on the bottle opening size and material properties.

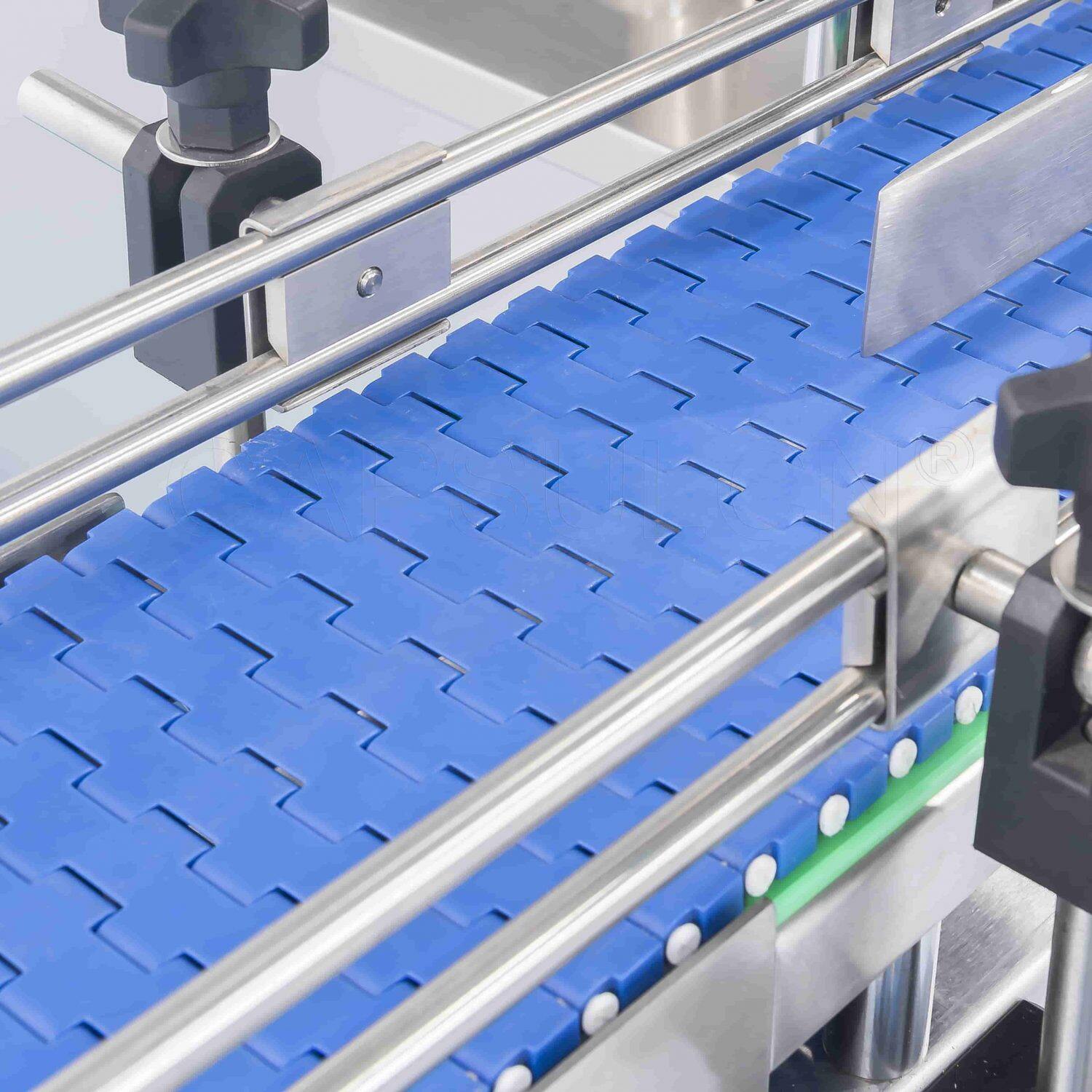

Conveyor belt

The conveyor belt is a track-type belt. Its job is to move bottles for different processing. The belt moves along a track, and the bottles move in the same direction. Operators can adjust the speed of conveyor belts to match the counting pace and prevent overloading. For hygiene and durability considerations, these belts are often made of food-grade rubber.

Interface screen

Every automatic counter would be equipped with an interface screen. It allows operators to control the machine and monitor its performance. This screen is usually a digital display, often touch-sensitive. This design provides great ease of use. In addition, it can detect errors for warning. For example, if there is no bottle in the filling position, the screen will show an alert to remind the operator to add one.

How to choose one suitable for your business?

Product types

Different products pose different filling requirement to the counters. Take pills and candies for example. Pills are usually round or oval, while candies and gum can come in many shapes, such as square or rectangular. If you want to use one machine for both, you need to make sure the machine can handle different sizes and shapes. Also, pills are usually hard, while candies can be soft and sticky. For soft candies or gum, the machine should have gentle transfer and dispensing functions to avoid damage or distortion. Moreover, if the candies are powdery or coated, you need to make sure the machine surface has an anti-stick treatment and it is easy to clean.

Speed

The speed of different types of automatic pill counters can vary. This mainly depends on the machine's design, features, and technology level. A single-channel counter uses one track to transport pills for counting. It can fill 30-50 bottles per minute. It is slow but cheaper, so it is suitable for small pharmacies or startups. A multi-channel counter has multiple tracks. It fills 100-300 bottles per minute. So it is better for large-scale production.

If you need a machine that can handle flexible tasks, a photoelectric sensor counter is a good choice. It has fast detection speed and low error rate. This machine fills more than 300 bottles per minute.

Five practical troubleshooting tips

You may meet many issues during operation of automatic pill counters. If you know how to solve them by yourself, it will save much cost and energy. Here are some common problems and solutions.

The accuracy of counting grains is decreased

It has several causes. Common include

- The glass window of the photosensitive receiver is covered by dust, so the dust should be removed and kept clean.

- The infrared emission tube is shielded by dust, so the dust should be removed and kept clean.

- The speed of the turntable is fast, and the speed is adjusted according to the diameter of the bottled medicine pellets.

Abnormal sound of equipment

There are some reasons and solutions.

- There is a friction sound on the glass turntable, check whether the baffle is loose.

- Whether there are broken medicine particles stuck in the gap of the glass turntable. If so, clean these particles.

The vibrator does not work

When this problem occurs, you’d better check

- Whether the fuse behind the electrical box is overloaded and burned out.

- Whether the vibrator is damaged.

The LED display does not light up

This may be because some parts are damaged, and you need to replace them with new ones.

- Check whether the transformer fuse behind the electrical box is overloaded and burned out.

- The transformer is damaged.

- The circuit board CPU is damaged.

The number of particles in the LED display cannot be set

- The keys are damaged.

- The circuit board CPU is damaged.

Boost your counting efficiency with Huada Pharma

If you're looking for pill counter manufacturers, Huada Pharma is the right choice. We are committed to providing reliable, accurate, and efficient machines to meet your needs. We have many models of automatic pill counters. They feature fast and precise counting for every type of pill, tablet, or capsule. We also provide excellent customer support, helping you with everything from setup to ongoing maintenance.