In the fast-moving world of pharmaceuticals, efficiency is king. For pharmaceutical or nutraceutical manufacturers, this often means finding the perfect efficient automatic capsule filler.

However, with the wide range of automatic capsule filler models to choose from, it can be overwhelming to find the one that gives you the most satisfaction. No worries! This guide will help you find the perfect equipment to boost your capsule output and revolutionize your pharmaceutical business.

Top 2 Picks for Best Automatic Capsule Filling Machines

To help you find the best automatic capsule filler from numerous options, we've selected the 2 best contenders based on output capacity, versatility, and ease of use.

1. Huada Pharma SFK-3000 Capsule Filling Machine: High-Volume Champion

The SFK3000 is an industrial grade machine ideal for high volume capsule production. It has a capsule filling speed of up to 176,400 capsules per hour. In addition, this model offers a wide range of capsule compatibility and can fill even the most challenging product types.

Features & Strengths

- The components used in the SFK3000 use advanced processing technology to ensure high precision and no sharp corners.

- The modular structure allows the machine to easily fill powders and micro-pellets

- The machine operates with low noise, smooth transmission and no oil leakage.

- It is very easy and quick to clean and replace the molds.

2. Huada Pharma CapCN-24/42 OEB Pro Capsule Filling Machine: Precision Master

The CapCN-24/42 OEB Pro stands out in applications that demand the highest level of precision. It features a high-precision dosing pan and tamping pin that minimizes dosing errors and ensures stable dosing control.

Features & Strengths

- The machine is equipped with high quality and durable electrical components

- Low energy consumption motor is adopted to fully realize energy saving.

- The dosing disk is adjustable, no need to change the dosing disk frequently, saving time and labor.

- Each moving part of the machine is sealed tightly to prevent powder from entering or leaking out as much as possible, ensuring a clean work site.

How To Select The Best Capsule Filler For Your Business?

Impressed by these top picks? While these popular models showcase the capabilities available, the best equipment for your business depends on your specific needs and production goals. Here's how to choose the automatic capsule filling machine that best suits your specific needs.

Before diving headfirst into comparing the specifications of various models, maybe you can take a step back and find out what your specific business needs are. This is critical to picking the right capsule producing equipment for your project. Here are some questions to help you determine your needs.

Question 1: Are you a high-volume manufacturer producing millions of capsules per day, or a small business just starting out?

Your production volume will directly affect the machine capacity you need. For a startup, a machine that can process millions of capsules per hour may be redundant, but for a high-volume business, an underpowered machine may bottleneck its production.

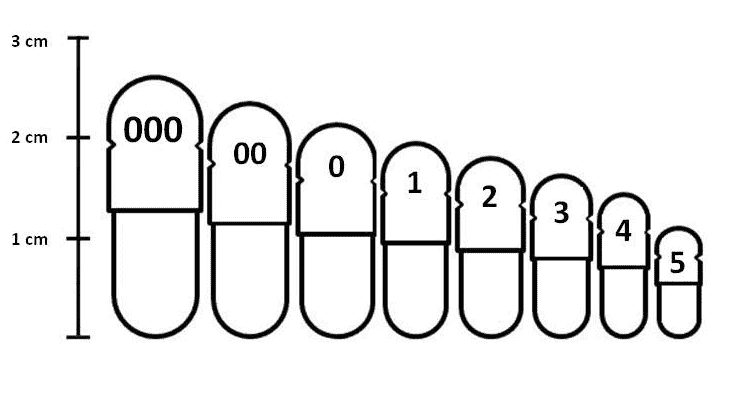

Question 2: Is a machine that can handle a single standard capsule size (e.g., size 00) enough, or do you need a versatile machine that can handle a variety of capsule sizes?

Capsule size and type is something you must consider when choosing a capsule filling machine, because you want to be sure you choose a machine that can produce the capsules you want.

Questions 3: What material are you going to use to fill your capsules?

Different capsule filler models may be good at handling varying materials. For example, some machines have specialized drying capabilities and excel at handling moisture-sensitive materials, while others are better suited to handling dense powders that require a robust tamping system.

Question 4: How much is your budget?

Honestly, budget is something you can never ignore. The price of an automatic capsule filler can vary significantly. You can find basic models for a few thousand dollars, while feature-rich industrial machines can cost hundreds of thousands. Before exploring your options, first you should determine how much of an upfront investment you can afford. Remember, the most expensive machine isn't always the best fit, the one that meets your specific needs is.

Question 5: How big is your available space?

Never underestimate the actual footprint of your capsule filling machine! Measure your existing available space and consider not only the machine itself, but also whether you need add-ons such as capsule feeders and product hoppers.

How to Find the Right Capsule Filling Machine Manufacturer?

Choosing a capsule filler is an investment, but it's not just about the equipment itself. You also have to build a relationship with the manufacturer. Here's how to find a reliable capsule filling machine manufacturer:

- Do they have a good industry reputation?

First, you need to research the experience and track record of your chosen capsule filling machine manufacturer in the industry. Make sure you find a company that has a long history of providing quality machines.

- Do they listen?

When contacting a capsule filling machine supplier for the first time, assess their willingness to understand your specific needs and answer your questions in detail.

- Are they there for you?

Inquire about these manufacturers' after-sales support options. Look for a manufacturer that is readily available for technical support and prioritizes customer satisfaction.

- Do they value technological innovation?

When choosing a manufacturer, you'll also want to consider whether they are committed to research and development of the latest capsule filling technology, so you can be sure that the machines they offer will meet your new production needs in the future.

- Can they offer customization options?

A manufacturer's ability to offer machine customization options is critical for future seamless integration of a capsule filler into your current production line.

- Do they have enough expertise?

Choose a manufacturer with in-depth application expertise in your industry such as pharmaceuticals or nutraceuticals. This ensures they understand your specific challenges and will recommend the best solution.

Conclusion

Always remember, a capsule filling machine can only be called the best if it is perfectly matched to your production goals! By choosing the right machine features and working with a reliable manufacturer, you'll be well on your way to advancing your capsule production business.