In the pharma industry, mixing is always needed. It keeps various powders distributed evenly. So the effectiveness of medicine won’t be affected during production. There are many equipment to be used for mixing. Bin blenders are the one of most popular types. They offer advantages in handling various volumes and types of powders. This post helps you have a further understanding of bin blenders and upgrade your pharma business.

What Are Bin Blenders?

A bin blender is a machine designed to mix bulk powders or granules. It mixes materials evenly by rotating or tilting the container. Bin blenders usually consist of a rectangular or cylindrical container. It is the main part used to mix powders and granules uniformly. The bin is attached to a frame that can rotate, allowing the machine to tumble and blend the contents well. While mixing, bin blenders keep the active ingredients, fillers, and excipients intact, ensuring their properties stay the same.

Bin blenders are commonly used in pharma manufacturing due to their flexibility and effectiveness. They are highly adaptable for different production scales, from small-scale R&D projects to large-scale commercial batches. Their design minimizes material handling and reduces cross-contamination risk. It is especially important for pharmaceuticals, where hygiene and accuracy are vital.

Five Common Types of Bin Blenders

Bin blenders are widely used in the market. They can be divided according to different ways to hold containers or their uses. Here are 5 types for your reference.

Fixed bin blenders

Fixed bin blenders typically involve a stationary blending unit. This bin can’t be detached. This design allows for seamless operation within a defined space. So it ensures stability during operation and reduces the risk of cross-contamination. Compared to other bin blenders, fixed bin blenders offer more simplicity and cost-effectiveness. They are easy to operate and maintain. Space efficiency is another advantage, as they require less floor space.

However, they are not so flexible for operation. Because the bin can’t be moved, it may slow down production when switching between different batches. This type typically handles one batch at a time. If you require high efficiency, this type may not be a good choice.

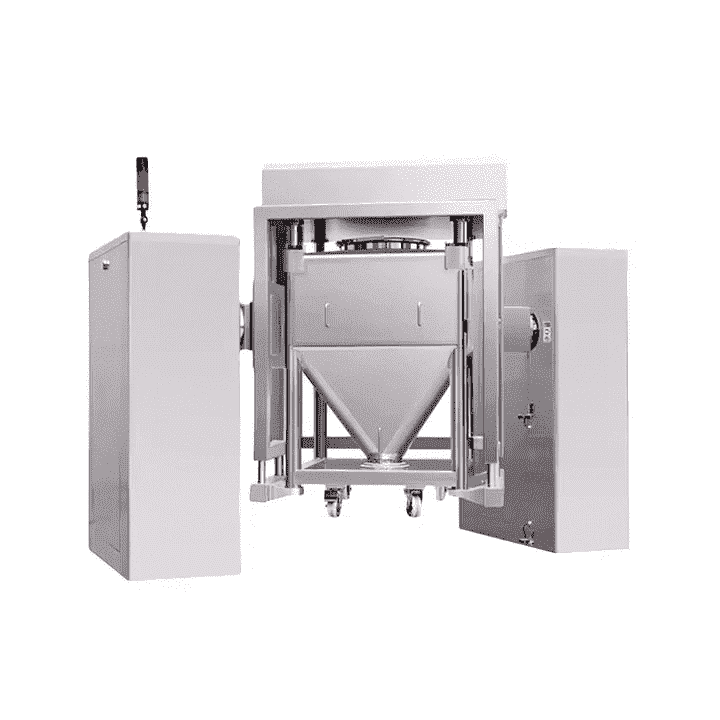

Movable bin blenders

These blenders allow for flexibility since the bin can be detached and transported easily. This is useful in various production stages and locations. This design supports seamless integration into different processes. Movable bin blenders also operate in a closed environment. It helps reduce dust and contamination risks. Unlike fixed bin blenders, movable models provide greater adaptability. They are useful for facilities that require quick changes between products. This makes them ideal for dynamic production environments.

However, movable bin blenders may have higher costs in the beginning. They also require careful handling during transportation to avoid spills or contamination.

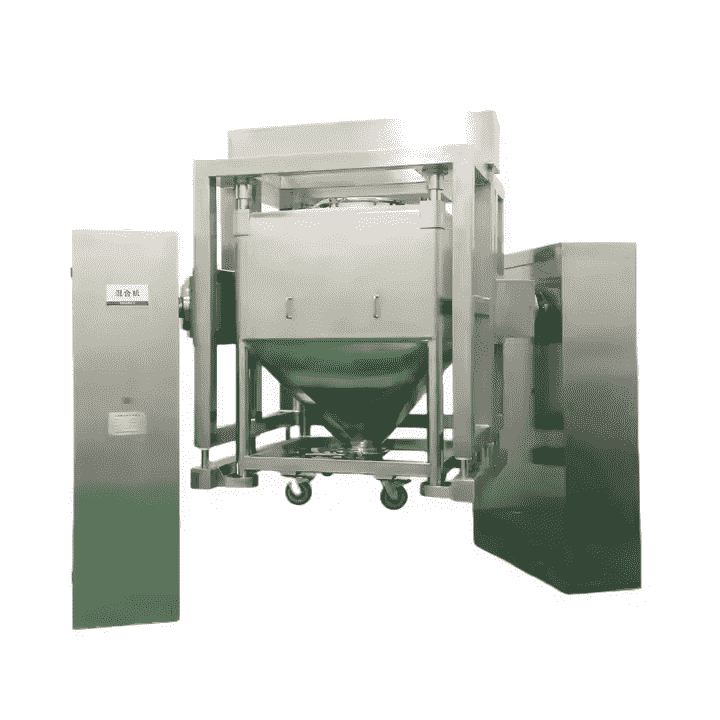

IBC bin blenders

IBC bin blenders are specialized mixing machines equipped with Intermediate bulk containers (IBCs). These blenders can efficiently mix large quantities of powders and granules. IBCs can hold between 300 and 1,200 liters. This design allows for thorough blending, ensuring uniformity in the final product. This type of blender excels in handling large volumes. It helps save time and improve efficiency in manufacturing processes.

But the initial investment for IBC blenders can be higher than for smaller mixing equipment. In addition, proper cleaning is essential to maintain hygiene standards, especially in the pharmaceutical and food industries.

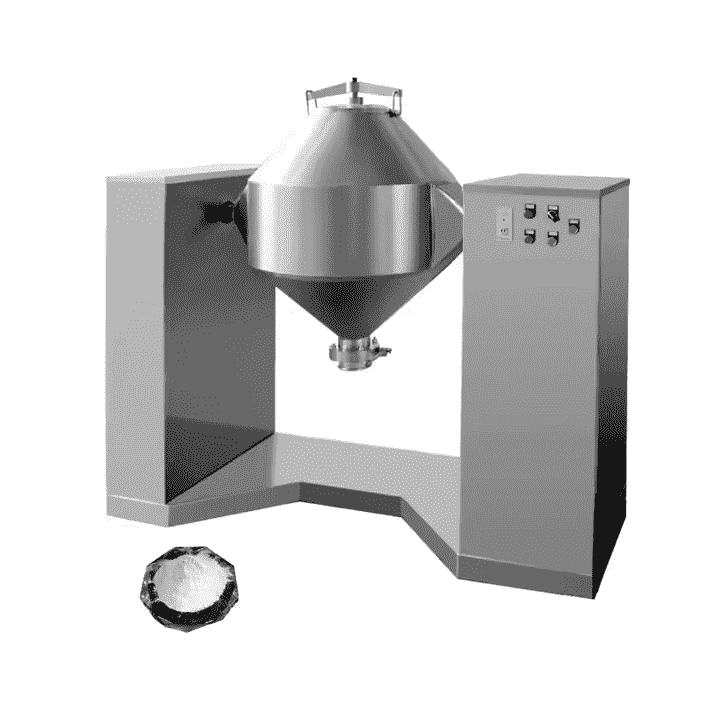

Conical bin blender

Conical is a popular shape of bin blenders. This design is greatly ideal for efficient mixing. The conical shape promotes excellent material flow while minimizing dead zones. The conical shape facilitates the movement of materials, leading to the thorough integration of active ingredients and excipients. They can achieve consistent blending. Easy cleaning is another important feature, as the design allows for quick and effective sanitation.

Conical bin blenders are good for handling granular powders, free-flowing powders, and finer powders. However, they are not suitable for powders with high moisture. Because it may be hard to mix them well in the cone. They require extra equipment or a handling process.

Laboratory or pilot-scale bin blenders

They are compact mixing machines designed for small batches in research and development settings. So they are always used for testing formulations, ideal for small-scale experiments. These blenders enable precise control over mixing parameters, helping researchers optimize formulations before scaling up. Compact size allows for efficient use of limited lab space. Moreover, simple operation makes them user-friendly for researchers and technicians. Please note that cleaning is key when using this equipment. It helps prevent cross-contamination between different batches.

How to Care for a Bin Blender?

Maintenance helps the machine operate more efficiently and smoothly. So you’d better maintain your equipment regularly.

Regular cleaning

When it comes to cleaning a blender, it requires internal cleaning and external cleaning. You should conduct internal cleaning after each batch to prevent cross-contamination. Suitable cleaning agents must be used for the materials processed. External surfaces require wiping to remove dust and maintain hygiene. Periodic disassembly of components like the bin and agitator allows for thorough cleaning.

Inspect for wear and tear

Parts of the blenders need to be checked regularly. Seals and gaskets should be checked to avoid contamination and leaks. Bearings and moving parts require thorough examination for signs of wear, such as unusual noise or friction. If you identify wear early, it can prevent larger issues and costly repairs. Proper lubrication is also essential. Because it helps prevent friction and overheating in these components.

Inspect safety features

Components for safety include safety interlocks, emergency stops, guards, etc. It is essential to make sure they work correctly every time. Because malfunction can pose serious risks to operators and equipment. Regular inspection helps prevent accidents and injuries, ensuring a safe working environment. Moreover, compliance with safety regulations is also vital for avoiding issues.

Replace worn parts

If you notice wear in seals, filters, or agitator blades, you’d better immediately replace them. Delaying can lead to leaks, contamination, and reduced blending performance. It is most important in sensitive medicines. In-time replacement enhances the lifespan of the blender and maintains consistent performance.

The End

In the pharmaceutical industry, bin blenders play a vital role. It ensures consistent, high-quality blending of powders and granules. From the versatile IBC bin blender to specialized options like laboratory models, each type offers unique benefits. They are suited to different production needs. When choosing a bin blender for your business, you need to consider batch sizes and material properties. Also, don’t forget to maintain your mixer properly for smoother operation.