Nearly every product requires carton packing for content protection and shipping. So many manufacturers always integrate a cartoning machine into their production line. This machine can handle various carton sizes and product types efficiently. It could be used in different industries, such as pharmaceuticals, food, and cosmetics. If you are new to this machine, you’d better know

- What is a cartoning machine in the packaging?

- What common types of cartoners should you know?

- What should be considered when you choose one?

What is a Cartoner?

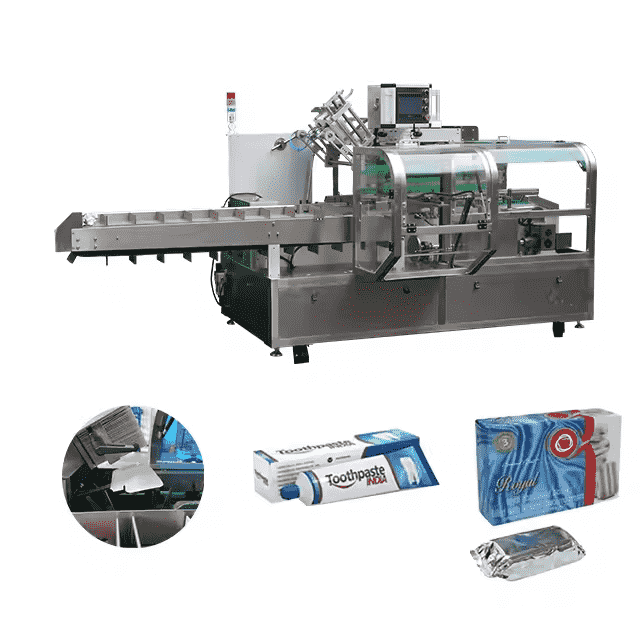

A cartoning machine is used to form cartons, fill them with products, and seal them for distribution. It handles a variety of packaging tasks, such as inserting items like bottles, blister packs, tubes, or sachets into pre-formed cartons. It also seals the cartons through methods like tuck-in, glue, or adhesive tape.

Cartoning machines are widely used in industries such as pharmaceuticals, food, cosmetics, and consumer goods. They improve production efficiency and minimize human error. More importantly, they can maintain uniform packaging standards. In addition, cartoners are suitable for both regular and irregular carton sizes and designs. It makes them meet different product packing requirements.

Six Common Types of Cartoning Machines

Turntable Cartoning Machines

The turntable cartoning machine is designed for simple and efficient cartoning. It mainly finishes packing with a rotating turntable. Empty cartons are sucked by vacuum and fed into the turntable. Then they are rotated to the folding mechanism to seal the bottom of the carton. Next, the products are placed into the carton. Then the turntable rotates the carton to another folding mechanism to seal the top of the carton. Finally, the completed product is transferred for delivery. You can check the video to see how it works.

This machine is ideal for packaging bulk items such as bottles, cans, or small boxes. It is commonly used in industries like food packaging and pharmaceuticals. It offers a cost-effective solution for high-volume production. While it is easy to operate and quick, it may not be suitable for delicate or irregularly shaped products.

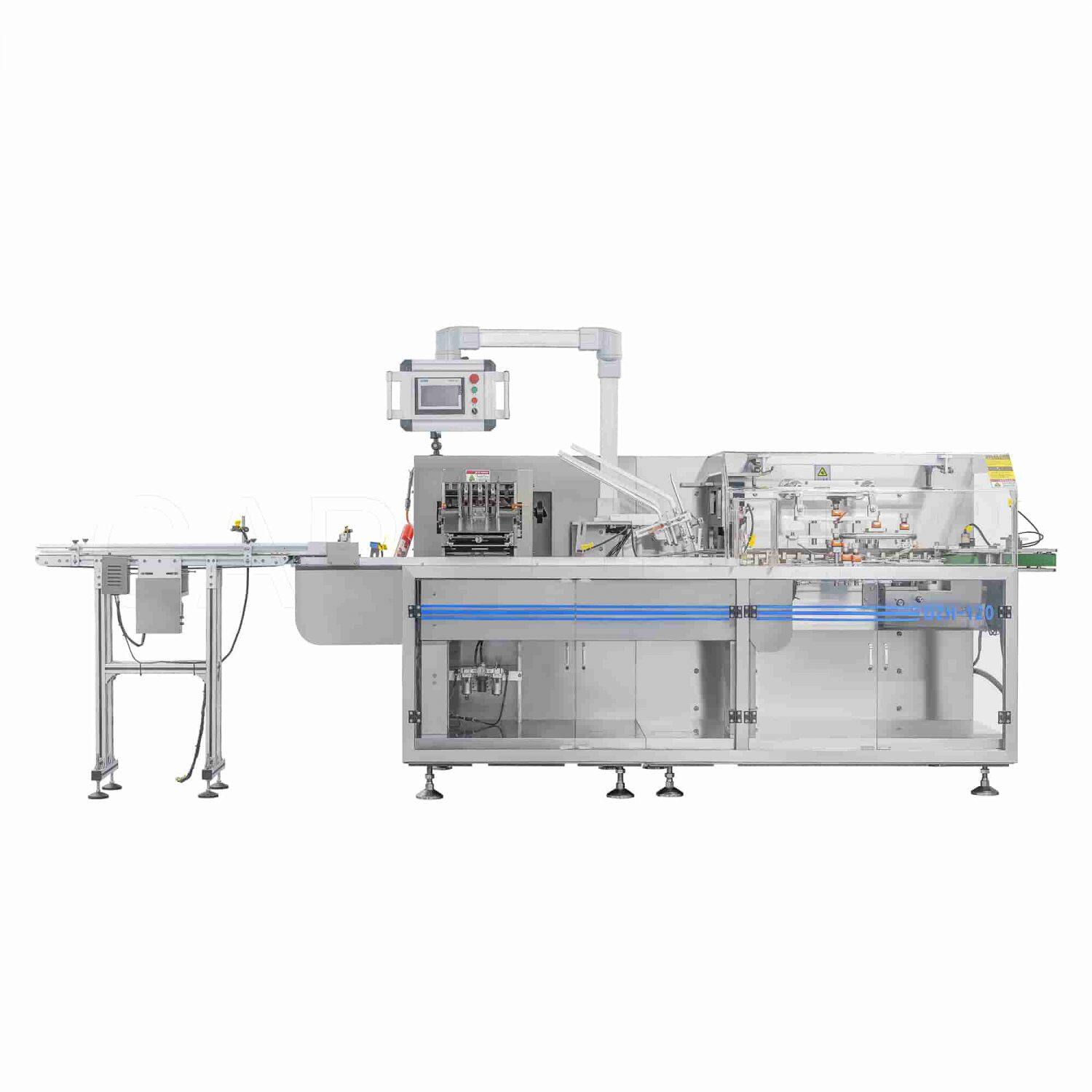

Horizontal Automatic Cartoning Machines

This model operates in a horizontal direction. The cartons and products require manual feeding and depend on the conveyor belt to transfer them. Cartons need to be folded into a box before the filling mechanism. Once the products are aligned with the open cartons, mechanical arms or pushers insert the items into the cartons. After the products are placed inside, the machine folds and seals the carton flaps. You can see the video to have a further understanding.

This machine is suitable for bottles, blister packs, and vials. So it is popular in the medicine, food and cosmetics industry. Horizontal automatic models also feature a high production capacity. They can process 30-120 cartons per minute. However, this machine covers a large workplace. And higher setup costs may be needed compared to simpler machines.

Cellophane Wrapping Machines

This equipment is used for single-box and multi-box packaging. It performs multiple functions, including feeding, wrapping, folding, sealing, shaping, and counting. It handles both single and collective packaging. The machine can also apply anti-counterfeiting pull lines, providing added security for packaged products. In addition, this machine has the function of ironing and spot ironing. This makes operations more efficient and user-friendly. Here is a video to help you understand the working principle.

During operation, the speed can reach up to 40 boxes/min. It features stable operation and low failure rate. This machine is mainly applied in medicine, food, health care products, tea, cosmetics, gifts, stationery, audio-visual products, etc.

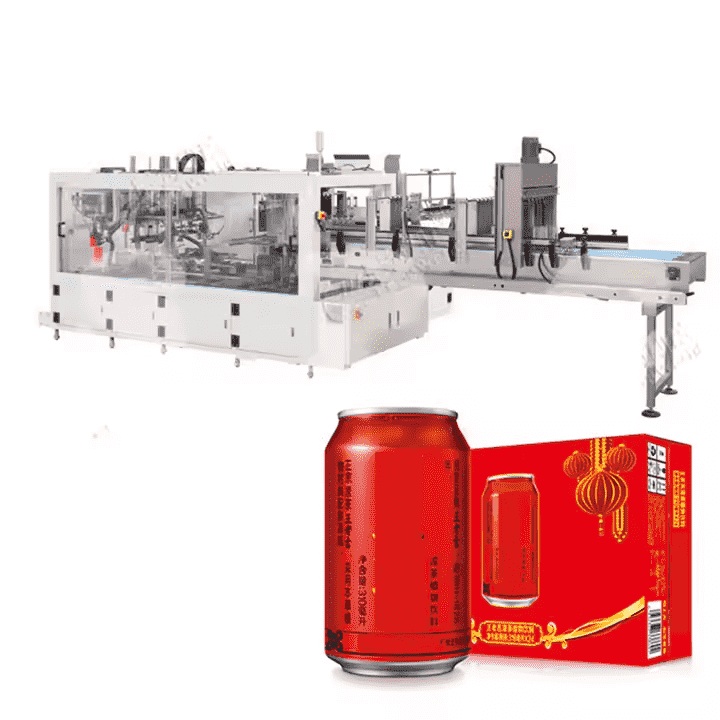

Wrap-Around Cartoning Machines

Compared to other cartoners, this machine doesn’t use pre-formed cartons. It wraps flat carton blanks around products. When the machine positions the product on a flat blank, it is then folded around it and sealed to form the final carton. This machine is ideal for products that require secure packaging, such as cans, bottles, or jars. It is widely used in industries like beverages, food, and household goods. Many manufacturers choose it because of the efficient use of materials and better product stability. But it may not be suitable for irregularly shaped items.

Continuous Motion Cartoning Machine

This machine operates by moving products and cartons continuously throughout the whole process. The horizontal automatic cartoners mentioned above belong to this type. This high-speed machine ensures a steady flow of products and cartons. So it is ideal for large-scale production lines. Continuous motion cartoners are commonly used in industries like pharmaceuticals and food. Regular cleaning and maintenance are required to keep running smoothly.

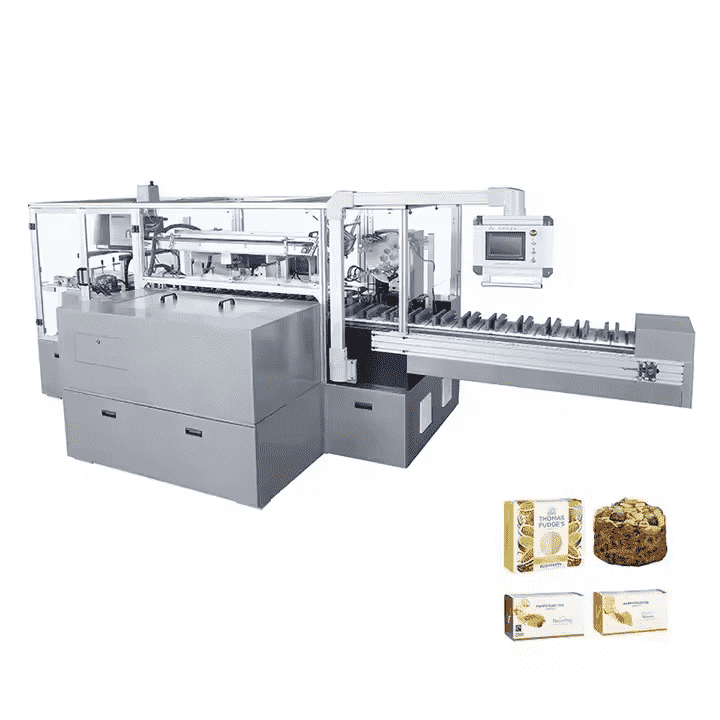

Intermittent Motion Cartoning Machines

This equipment runs with pauses during the packaging process. It always stops at steps for loading or sealing. So the packing efficiency is slower than continuous motion machines. This design makes it suitable for products that need careful handling or precise placement, such as fragile items, and irregularly shaped products. For example, it can handle packaging tasks for glass vials. This machine is also ideal for small to medium production runs or products with high packaging quality standards.

How to Choose a Cartoning Machine Suitable for Your Business?

Product Types

The first thing to consider is the products you need to pack. Different machines work better with certain products. For example, horizontal cartoning machines are good for bottles or blister packs, while vertical models are better for upright items like jars or tubes. If your products are fragile or need special care, choose a machine that handles them gently.

Space and Budget

You should also think about the space available in your factory and your budget. Larger machines may need more space and cost more. Compact machines can save space and cost less but may not handle as many products. You need to choose a machine that fits your space and budget.

Ease of Use and Maintenance

If a machine is easy to use and maintain, it can save much time and reduce repair costs. So you’d better look for a machine with simple controls and quick changeover features. Also, you should check if replacement parts are easy to find and if technical support is available. This helps keep your machine running more efficiently.

Upgrade Your Packing Efficiency with Huada Pharma

Huada Pharma provides various types of cartoning machines to meet the needs of different industries. Whether you require horizontal or turnable cartoners, we can quickly match your needs. Our machines work fast for big jobs or carefully for smaller, delicate items. Besides, Huada Pharma helps businesses with setup, use, and maintenance. Our technical team is ready to help you pick the right one and keep it running well. With simple and dependable solutions, Huada Pharma has helped 30,000 clients to get their satisfied machines.