In the pharmaceutical industry, especially in capsule production, there are some terminologies you cannot do without. You must have come across these words once or twice. However, do you know what they mean and how they are used?

You will be provided with in-depth knowledge of some words related to capsule production, including their definitions, and other important knowledge related to them.

1. Active pharmaceutical ingredient (API)

A drug (capsule, syrup, tablet, etc.) comprises two main components: the active pharmaceutical ingredient and excipients.

An active pharmaceutical ingredient (API) is the biologically active ingredient in a drug that produces the required pharmacological effect. These pharmacological effects could either be diagnosis, treatment, or cure of a disease.

Excipients are the inactive ingredients in the drug that help to facilitate the action of the active pharmaceutical ingredient (API).

The quantity of API in a drug determines its potency/strength. There are two types of APIs, synthetic and natural API.

Examples of synthetic Active Pharmaceutical ingredients are aspirin and diphenhydramine. Natural APIs are Remicade, Humira etc

2. Altered Release

Altered release dosage is also known as modified release dosage. The capsule contents are released at a delayed time from the time of administration, according to the capsule material and the nature of the drug formulation.

Altered release dosages are preferred to conventional dosage forms because they have better efficacy, lesser adverse effects, and better convenience and performance, among many others.

Capsules have an enteric coating that protects the drug formulations from the gastric acid in the stomach. This allows the drug to be released in the small intestine where there is optimal absorption of the drug into the body system. The enteric coating is made up of cellulose acetate phthalate, mixtures of waxes, and fatty acids, which are insoluble in an acidIc (gastric) environment but soluble in an alkaline medium(small intestine).

The release rate of the capsule content is regulated by the hydrophobicity of the drug and the capsule’s excipient. For the rapid release of water-soluble drugs in hard capsules, the excipients should be hydrophilic and neutral.

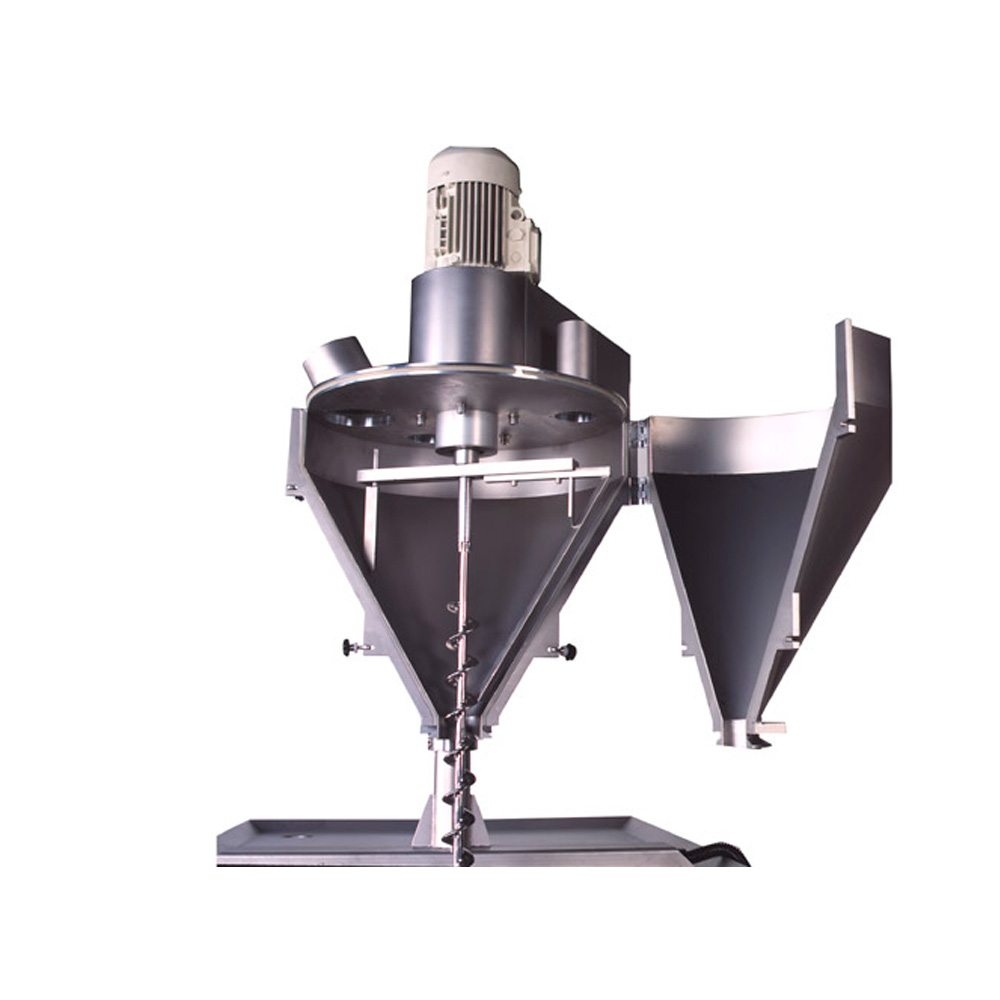

3. Auger Filling Machine/Method

Auger filling machine or Auger filler is the equipment for dispensing the drug formulation inside the capsule. The amount delivered is usually predetermined, as the drug is placed in a vessel called a hopper, and the precise dose is delivered into the capsule.

The delivery of drugs with the auger filler is through the dosing feeder with a rotating screw, guided by a funnel. The hopper is filled with the material for continuous gravimetric and volumetric filling of the capsules.

The auger filler is not only limited to capsule production. It fills containers with liquid, powdery, semi-liquid, and granular materials.

The auger filler method helps create a precise and accurate dosage of drug formulation in a capsule. The type of material to be filled in on the rotating speed of the hopper, capsule size, and the time the capsule spends under the hopper.

A slow-rotating hopper increases the fill weight of the capsule. If you are still confused about determining the type of material to use, you should consult with your supplier.

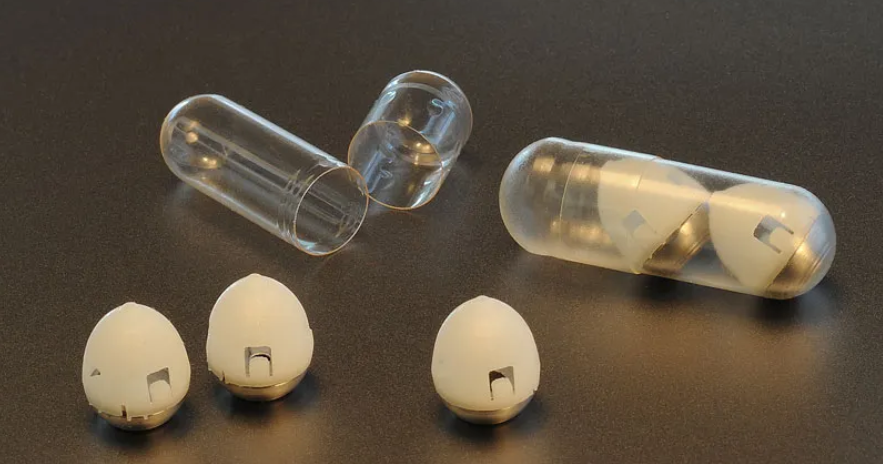

4. Body

What do you call the body of the capsule?

The body of the capsule is the lower part of the capsule. It is the actual frame the drug formulation is placed in before the capsule is sealed.

The capsule body is usually filled with the auger-filling machine.

5. Cap or Caps

Does the cap sound familiar? The capsule is divided into two main parts, the body, and the cap. They are cylindrically-shaped

The cap is the upper part of the capsule, it has a slightly larger diameter than the body. The cap and the body perfectly fit to form a closed capsule.

Empty capsules are called hard caps, caps, or gel caps.

6. Capsule

A capsule is a drug enclosed within a shell. The shell protects the contents from being digested in the stomach to produce an effective pharmacologic effect.

There are two types of capsules, Soft gel, and Hard gelatin.

The soft gel capsules are usually semi-transparent and filled with liquid drugs. It is easier to swallow compared to hard gelatin capsules. The materials filled in soft capsules include neat substances like oils, solutions, suspensions, or paste.

The shape of the soft gel capsule can come in different forms and sizes, including pear-shaped, ovoid, cylindrical, etc.

Hard gelatin capsules are applied to dry active ingredients. They are divided into two halves and are usually filled with powder or pellet drugs. The materials filled in hard gelatin capsules are solids, semi-solids, or liquids like alcohol and oils.

7. Capsule Filler

A capsule filler is a device used in filling empty capsules with drug formulations. There are two categories of capsule filler, the personal capsule-filling machine, and the industrial capsule-filling machine.

The industrial capsule filler is used for large-scale productions in pharmaceutical industries. The personal capsule filling is used for personal medications. It can also be used for small-scale production.

There are three types of capsule filling machines,

- Manual filling machine

It can be used to fill up to 800 capsules, and it is operated manually.

- Semi-automatic filling machine

It has both manual and automated operations. They are more hygienic compared to manual fillers.

- Automatic filling machine

The automatic filer is operator-independent. All operations are completely automated including the dust extractor, damage capsule sorter, and empty capsule ejector.

8. Colourant

You must have noticed that most drugs and capsules are colored. Do you know there are reasons for that?

Colorants are dye or pigment additives to drug production. They impart special effects color to the drugs.

Some of the reasons capsules are colored are

- For easy identification, especially for individuals on multiple dosage regimens.

- For brand identification

- For photo-sensitive active ingredients

- For aesthetics

Pharmaceutical colorants could either be water-soluble pigments or water-insoluble pigments. They could also be natural dyes or synthetic dyes.

Natural dyes, just like the name implies, are mainly derived from plants. Examples of natural dyes are, annatto, chlorophyll, spirulina, saffron, and vegetable carbon (used to make black-colored capsules). They are toxin-free, eco-friendly, and known to have some nutritional value.

Synthetic dyes are made from chemical compounds, such as azo dyes, triarylmethane, erythrosine, quinoline yellow, indigo carmine, and many others. Synthetic pigments are mainly from Iron oxides, like black iron oxide, red iron oxide, and yellow iron oxide as well as Titanium oxide.

9. Dependent Filler

Dependent filler is a term used to describe a capsule dosing machine that uses the capsule body to measure the powder fill directly.

An example of a dependent filler is an auger filling machine. It is essential in achieving a uniform fill weight, especially when the capsule is filled.

10. Diluent

Diluents are excipients used in capsule production to increase the fill weight and improve the uniformity of the drug formulation. They are usually physiologically inert, toxic-free, and physiologically and chemically stable, both by themselves and in combination with the active pharmaceutical ingredient.

There are two forms: Natural diluents and the common diluents.

The natural diluents include starches, which are hydrolyzed or partially pregelatinized. The common diluents are lactose, sorbitol, mannose and xylose.

11. Disintegrant

Disintegrant is an excipient used in capsule production that facilitates the disintegration and release of the active pharmaceutical ingredient (API), especially when in contact with moisture.

There are two types of disintegrants: the traditional disintegrant and the super disintegrant.

An example of a traditional disintegrant is starch. The super disintegrant are of three different types, which are

- Natural super disintegrant, e.g. Alginic acid and its derivatives

- Semi-synthetic super disintegrant e.g croscarmellose

- Synthetic super disintegrant e.g. crospovidone

Some factors that could affect the function of disintegrant, such as

- Water absorbing quality

- Stability

- Inertness

- Water solubility

12. Dosator

Dosator is a device used to fill accurate doses of drug formulation into the capsule bodies.

It has sensors, a conveyor system, a capsule hopper, and other parts that work efficiently together to ensure accurate results. The dosator goes through six stages to fill the capsule body:

- Preparation phase

During this phase, the command is inputted through the control panel before starting the machine.

The capsule and powder hoppers are filled with capsules and powder(drug formulation) respectively.

- Incoming phase

The dosator cavities are filled with the powder material in a downward movement.

- Compaction phase

The dosator compresses the powder material into the dosator cavities, which is facilitated by the dosator plunger. This action creates more space in the dosator cavity for more powder materials.

- Retraction phase

Once the dorsal cavity is filled with the powder material, the dosator plunger is retracted.

- Doctoring phase

The dosator removes excess powder material from the dosator pin at this stage. This process maintains the right amount of powder filled in the capsules

- Ejection phase

The powder material is ejected into the capsules. The empty capsules move to the filling station through the conveyor belt. The conveyor belt also removes the cap from the capsule body for ready as easy filling.

The dosator machine is crucial in capsule production because it ensures reliable and precise filling of dry powders.

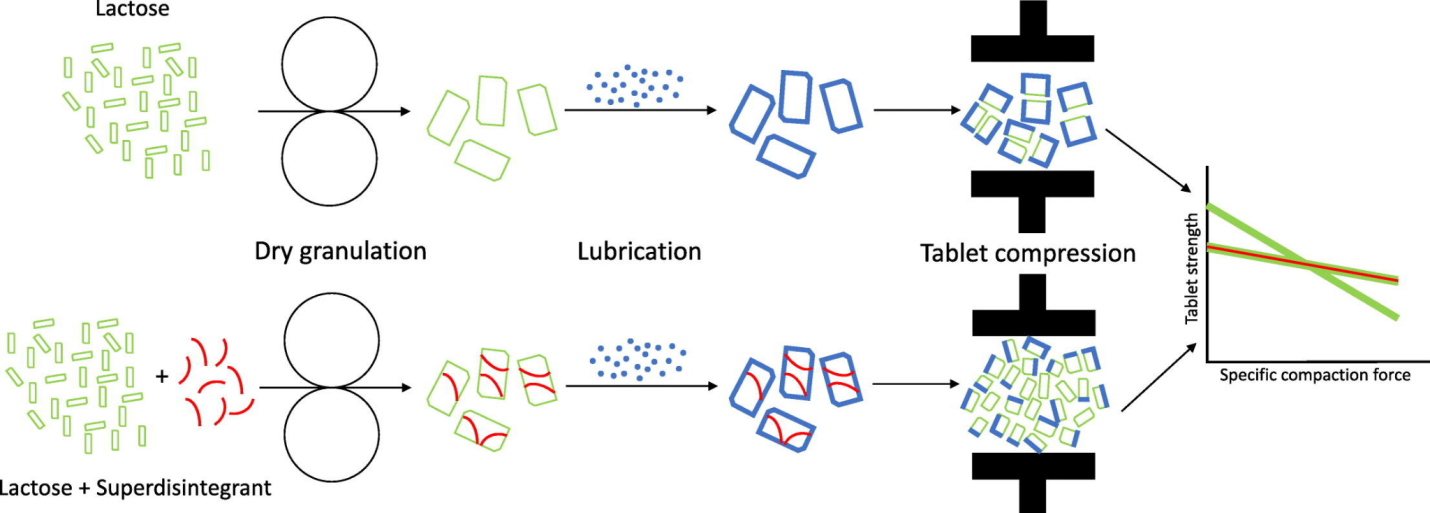

13. Dry Granulation

Dry granulation is a method used in capsule production for the compression and compaction of dry powder particles. It involves pre-compression or double compression of materials that would not be easily compressed.

The counterparty technique is known as wet granulation, which involves the formation of granules using a granulating fluid.

The dry granulation technique is used for moisture-sensitive active pharmaceutical ingredients (API) and temperature-sensitive substances that could be degraded by wet granulation.

For effective dry granulation. the active pharmaceutical ingredient (API) and diluents must have stable inherent binding and cohesive properties.

Conclusion

If we were to discuss all the terminologies of capsule production, we would not be able to exhaust it. However, with this information, you can consider yourself higher than an amateur, as you have read through basic and important terms you need to know about capsule production.

For more information on machines and other pharmaceutical equipment you need for capsule production. You can consult us now.