Liquid filling equipment is used to fill an exact amount of liquid into any container such as a capsule or bottle. This process requires high accuracy and consistence, especially in pharma industry. This liquid fill machine is suitable for filling various liquids, such as water, oils, syrups, etc. Some viscous substances like gels and pastes are also included. This liquid filling equipment is used in various industries such as food and beverage, pharmaceuticals, cosmetics, etc.

There are many types of liquid filling machines to choose from. Each has unique features. You must have a basic understanding of liquid filler machines and then make a wise choice for your business.

Manual Liquid Fillers

This is designed to fill liquid into containers totally by hand. This manual liquid filling equipment is not equipped with any electricity or complex system. So it is easy for operation. For this type of liquid filling machine, the amount of liquid is controlled by the screw. And there is a lever needed to be pulled for dispensing the liquid. The disadvantage of manual liquid filling machines is low efficiency. But it costs less compared to automatic ones. Because manual liquid filler only has a nozzle to complete filling and it requires much time and effort from operators. So this manual liquid filler is suitable for new bies or small business.

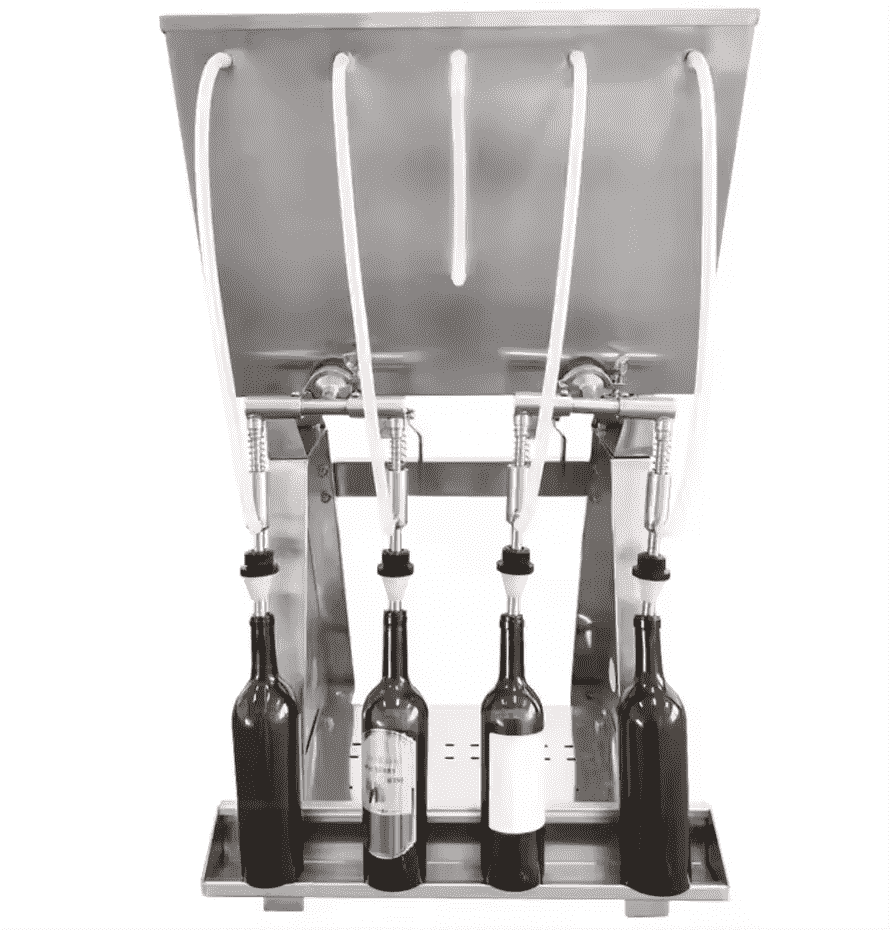

Semi-Automatic Liquid Filling Machines

This type of liquid filling machine combines hand operation and auto process. The filling process is usually finished by the machine itself. Common hand work include pour the liquid into the hopper, place the containers under the filling nozzles, etc. Besides, there is always a touchscreen equipped in this machine. Operators use it to control and monitor the whole filling process.

Semi-auto liquid filling machines offer more efficiency and production than manual liquid fillers. It also costs less than fully automatic machines. So this liquid fill machine is a good middle-ground option if you need automated process but less fees.

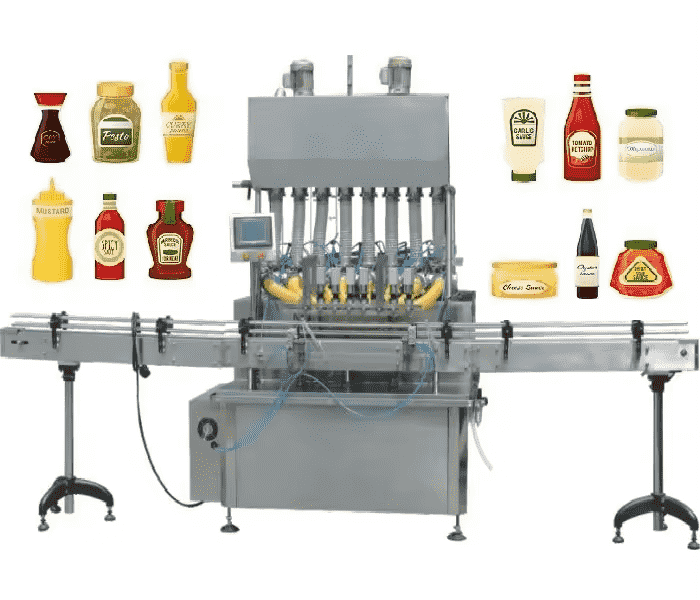

Fully Automatic Liquid Filling Machines

These liquid fillers are fully automated. It means they can perform the entire filling process without manual operation. They move containers into right place by themselves, and fill containers with amount of liquid you need. Then they move containers down the line for sealing. These liquid fillers can be integrated into a larger production line. For example, after filling, the container can be automatically labeled, and packed with a blister packaging machine. It helps streamline the entire filling process.

Fully automatic liquid fillers are suitable for mass production in big factories. Because they poses higher requirement for efficiency and precision.

The above three types of liquid filling machines are divided according to automation level. Next, let’s see five more types according to filling mechanism.

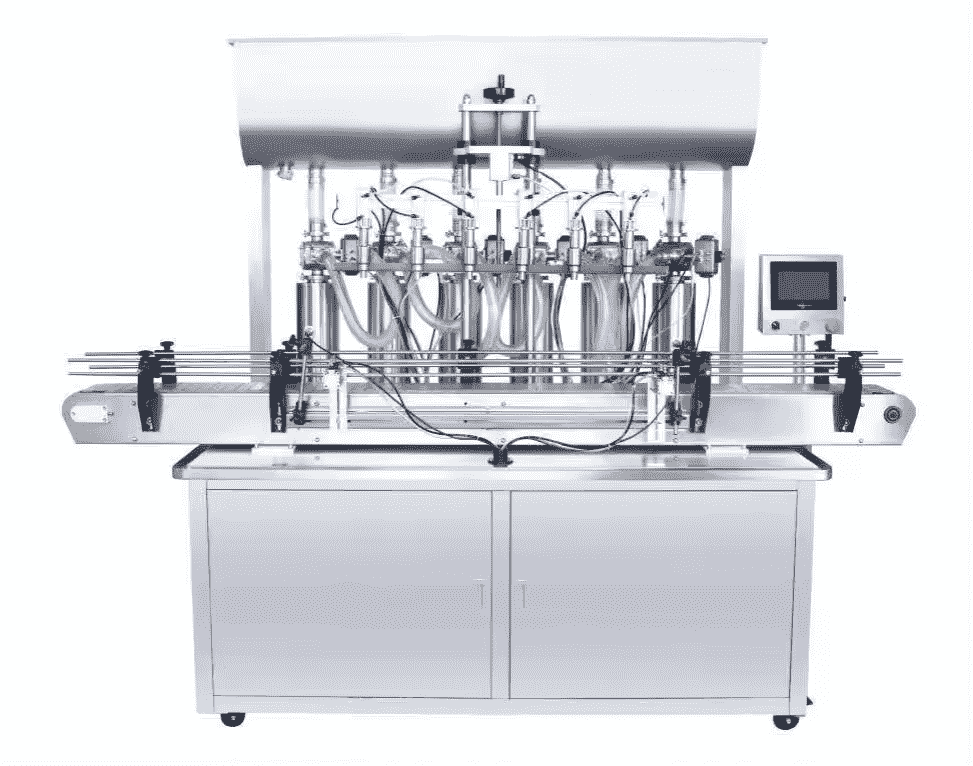

Piston Liquid Filling Machines

Piston liquid filling machine is made for thick liquids like creams, pastes, sauces, or gels. It is ideal for special production needs and avoids clogging. Piston filling machines use a piston-and-cylinder system to measure and dispense liquids. There are single piston and multi-piston liquid filling machines. Generally, multi-piston liquid filling machines on the market can have 2, 4, 6, 8, or even more pistons. These pistons work together, filling multiple containers at the same time. Compared to single piston liquid filling machine, this multi-piston design greatly increases production efficiency. So it is more suitable for medium to large production lines.

The piston liquid filling machine working principle is easy. When the piston pulls back, it creates a vacuum. So the liquid is sucked into the cylinder from the hopper. Next, as the piston pushes forward, it forces the liquid out of the cylinder. The liquid is then into the container through the filling nozzle. The amount of liquid dispensed is determined by the size of the cylinder and how far the piston moves. This allows for precise control of the fill volume.

Digital Liquid Filling Machines

This digital liquid filling machine uses digital controls for the filling process, making it very precise and easy to use. Settings like filling amount, speed, and liquid type are adjusted through a touch screen or digital interface. For example, switching from filling water to oil doesn’t require manual adjustments of the machine parts. It just needs a few taps on the digital control panel to finish. This provides great efficiency in the filling process.

The digital liquid filling machine offers high flexibility. It also allows quick changes between different filling tasks. This digital control liquid filling machine makes them suitable for production lines where product types or packaging sizes change often. In addition, these digital control pump liquid filling machines usually come with real-time monitoring and data recording features. It ensures more precise and controlled operations.

Aseptic Liquid Filling Machines

This aseptic liquid filling machine is specifically made to fill liquids in a completely sterile environment. It makes sure that both the liquid and the container stay free from bacteria or other contaminants during the filling process. The liquid filler requires a much higher level of cleanliness than GMP requirements. The aseptic liquid filling machine is equipped with HEPA filters and clean rooms. This keeps the air around the filling area completely clean for processing. The aseptic liquid filling machine helps prevent any contaminants from entering.

Before using the aseptic liquid filling machine, strict sterilization is needed. And the containers are sealed immediately after filling in a sterile way. Therefore, these aseptic liquid filling machines are mainly used in high-risk industries like medical, pharmaceutical, and certain food and beverage sectors. They all require strict sterile conditions.

Gravity Liquid Filling Machine

This gravity liquid filling machine depends on gravity to fill containers with liquid. Gravity liquid filling machine is specifically designed for filling thin, free-flowing liquids like water and juices. These liquid's viscosity is low enough that it flows easily through the machine. So they don’t need pumps or extra pressure. In addition, gravity liquid filling machine is also suitable for non-carbonated liquids that don’t require pressurization during filling. Examples include oils, cleaning solutions, and liquid soaps, etc. If adding pressure on them, it could cause foaming or bubbles.

Its operation is simple. The gravity liquid filling machine works by positioning containers under filling nozzles. The liquid flows from a reservoir above the containers, guided purely by gravity. Compared to other types, this simplicity makes it easy to use and maintain, with fewer moving parts.

Overflow Liquid Filling Machine

The overflow liquid filling machine is used to ensure that each container is filled to the same level, regardless of container size or shape. This overflow liquid filling machine uses a special nozzle system. It allows excess liquid to overflow and be collected. This ensures that each bottle is finished with same level, even if the bottles have different volumes.

Overflow liquid filling machines are more suitable for thin and free-flowing liquids like water, and cleaning solutions. The overflow system works efficiently with these types of liquids, ensuring smooth and quick filling. If your products require a consistent liquid level with transparent packaging, the overflow liquid filling machine is a good choice.

How to Choose Liquid Filling Equipment?

Material Properties

Viscosity is important to consider. Liquids can have different levels of thickness. Some are thin like water, while others are thick like pastes. Different types of liquid filling machines are suitable for different levels of viscosity. Additionally, you should attention if your liquid has solid particles, like seeds in a sauce. In this case, you’ll need a filler that can handle these without causing clogs or uneven filling.

Container Types and Sizes

Different machines handle different container shapes. Whether they are square, cylinder, or round, you should make sure your liquid fill machine can handle the container type well. For example, piston fillers are better for jars or non-standard shapes. Also, if you use various container sizes, look for a machine that can easily adjust. So there is no need for extensive reconfiguration and it helps save much time.

Production Volume

You should know how much production is suitable for your business. For small batches, a manual liquid filler or semi-automatic filling machine might be sufficient. For large-scale production, you’ll need an automatic liquid filler that can handle high volumes efficiently. You also should consider how many units you need to produce per hour or day. This will help you choose a liquid fill machine with the right filling speed to meet your production targets.

Elevate Your Production with Huada Pharma

Huada Pharma offers a wide range of advanced liquid fillers. They meet the demands of various industries, including pharmaceuticals, food, and cosmetics. With rich experience in pharmaceutical engineering solutions, Huada Pharma’s liquid filler ensures high precision, reliability, and efficiency in production processes.

Whether you need a machine for filling small dropper bottles or large-scale liquid containers, it is all available. We offer customized solutions that cater to different product specifications, production environments, and industry requirements. You just tell us what you need, and we would quickly select the most suitable equipment as required. Feel free to contact us now.