For years, pharmaceutical and nutraceutical companies have grappled with limitations in capsule filling methods. Traditional techniques were often unreliable and slow, hindering production efficiency.

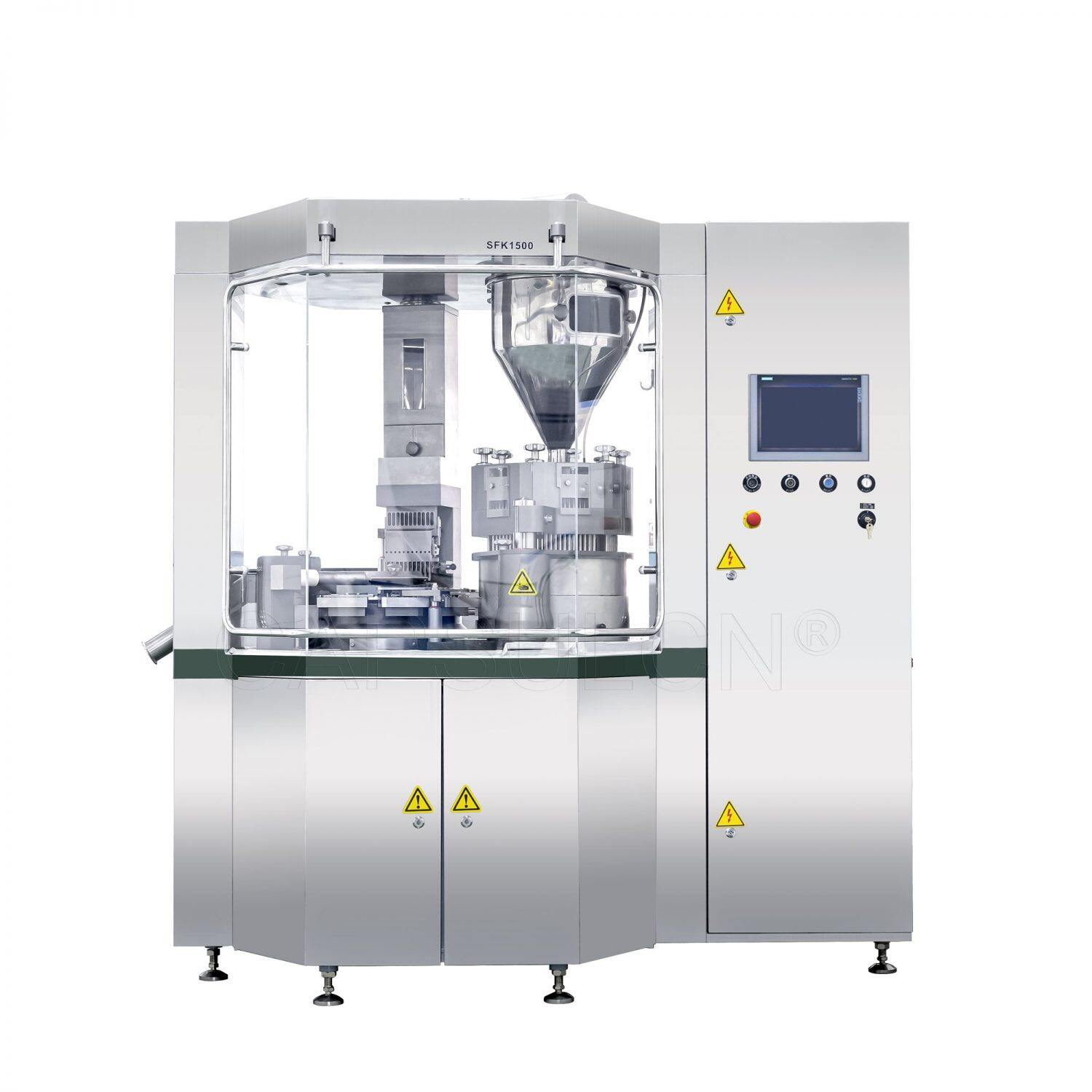

Enter dosator capsule filling machines. These innovative machines utilize advanced dosing tools to ensure accurate and consistent filling of powders and granules. This technology not only revolutionizes capsule filling but also simplifies the entire process, leading to significant time and resource savings.

What is a Dosator Capsule Filling Machine?

This innovative technology utilizes a specialized tool called a dosator to ensure flawless capsule filling, every single time. Unlike imprecise traditional methods, dosator machines guarantee consistent powder and granule quantities within each capsule.

In addition, most dosator capsule fillers boast built-in compactors, essentially mini pistons or vacuum systems. These compactors establish a consistent powder density within capsules, leading to a superior end product.

How Does Dosator Capsule Filling Work?

We already know that the dosator capsule filling machine uses a specialized tool to achieve consistent filling. But how exactly does it work? Let's dive into the magic behind it.

Step 1: Preparing the powder bed

The foundation for perfect capsules lies in a smooth and stable powder bed. At first, the dosator capsule filling machine carefully prepares this bed to guarantee a steady flow of powder throughout the filling process.

Step2: Collecting the powder

Then, our key tool, the dosator, enters the powder bed. Its chamber is carefully designed to collect the exact amount of powder needed for each capsule.

Step3: Compacting the powder

TMore than just dumping powder, the dosator utilizes a built-in piston or vacuum to compact the powder. This step guarantees consistent density and volume within each capsule, further ensuring precise medication dosing for optimal effectiveness.

Step4: Filling and Sealing the Capsule

Following the accurate measurement and compaction stages, the dosator moves towards the capsules, typically positioned on a rotary table or conveyor belt. It then precisely fills each open capsule, minimizing powder spillage. Finally, the machine seals the capsule, completing the process.

What Are the Benefits of Using Dosator Type Capsule Filling Machine?

In today's fiercely competitive pharmaceutical industry, both efficiency and quality are top priorities. A dosator capsule filling machine can be a strategic investment that empowers your business for future success. Here's a look at how using dosator technology benefits your company:

- Traditional capsule filling methods are prone to inconsistencies, leading to product rejection and material wastes. Dosator capsule filling machines solve this problem by ensuring consistent and precise filling with every capsule. This translates to a significant reduction in waste and the need for rework, ultimately saving you money on raw materials and production time.

- Dosator capsule filling machines automate the capsule filling process, and there is no need for manual intervention. This dramatically increases production speeds compared to traditional methods. You can fill more capsules in less time, allowing you to meet higher order demands and expand your business scale.

- Traditional capsule filling processes are often plagued by equipment malfunctions and the need for frequent cleaning and maintenance. Dosator capsule filling machines are different. They are usually more durable and require less downtime for maintenance.

- The consistent and precise filling capabilities of dosator machines ensure the final product adheres to strict quality control standards. This means that your capsules are consistent in weight, content and potency. By offering this high quality products, you can gain a competitive edge in the market.

What Are Common Products that Thrive with Dosator Filling?

Now that we've learned about the impressive benefits of the dosator capsule filling machine, lets dive into some common products that thrive on its use.

- Pharmaceuticals: From life-saving medications to common pain relievers, dosator filling machines ensure consistent and accurate doses of active ingredients in each capsule. This translates to reliable efficacy and patient safety.

- Dietary Supplements: The production of vitamins, minerals, herbal extracts, and other dietary supplements hinges on precise filling. Dosator capsule fillers ensure vitamin capsules contain the exact amount of each ingredient, guaranteeing consumers receive the intended health benefits.

- Cosmetics: The cosmetic industry also utilizes dosator filling machines. These machines fill capsules with various cosmetic ingredients, such as powdered makeup formulas or skincare serums.

How to Choose the Right Dosator Capsule Filling Machine?

Dosator capsule filling machines offer a reliable solution for companies looking for consistent, high-quality capsules. However, with so many options out there, choosing the right machine for your specific needs can feel overwhelming. Don’t worry! Here are some key considerations to guide you through the selection process.

1. Understanding Your Production Needs

First things first, take a good look at your current and future production volume. Are you a small startup or a high-volume manufacturer? If you're a startup or have a mini product line, a semi-automatic dosator machine is enough for you. But for large scale production, a fully automatic dosator filling machine will be your champion.

2. Considering Capsule Compatibility

Not all capsules are created equal! Different sizes and materials require compatible filling machines. Double-check the size and type of capsules you plan to use and be sure the machine you choose can handle them perfectly.

3. Accuracy is a Top Priority

If you work in the pharmaceuticals industry, you should know how accuracy is important. Investigate the dosing accuracy of each dosator filling machine you consider. The greater the accuracy, the more consistent the filling will be across each capsule. And sometimes, even subtle differences in dosing can affect the efficacy of your product.

4. Seeking Speed and Efficiency

Think about the production speed you want. How fast do you need your machine to fill capsules? Some dosator filling machines prioritize precision for small batches and high-value products, while others may be good at producing capsules at lightning speed.

By carefully considering these factors, you can select the perfect machine to propel your business forward. Remember, this is an investment in your future success, so take your time and do your research!