Confused about dosator vs. dosing disc or unsure which type of capsule filling machine is best for your product? Well, wonder no more! This article will provide a clear explanation of these dosing mechanisms and the capsule filling machines that use them.

We'll introduce you to their key differences and help you make an informed decision according to your specific needs.

What is Dosator Type Capsule Filling Machine?

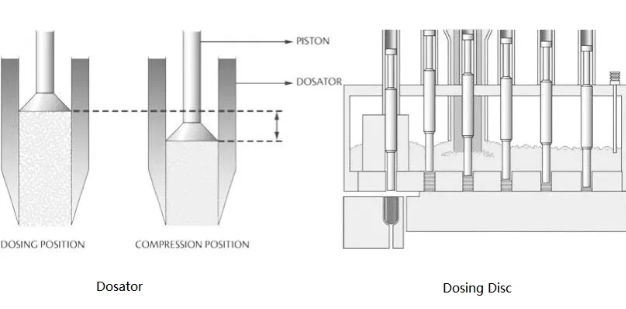

The dosator capsule filling uses a metering device for powder dosing and filling. This type of machine can handle a wide range of free-flowing powders with high accuracy. The dosator is the dosing device inside the capsule filling machine. It uses a controlled-opening tube with a movable piston to capture, compress and deliver a specific amount of powder into the capsule body.

How Does a Dosator Capsule Filling Machine Work?

Here is how the dosator capsule filling machine works. First, empty capsules are loaded into the capsule hopper and wait to be sent to the filling station. At the same time, the powder is stored in the hopper above the dosator.

Next, the dosators come in handy. Dosators are usually cylindrical tubes with a controlled opening at the bottom. Each dosator dips down through the controlled opening into the powder bed, capturing a specific powder volume inside the tube. A movable piston inside the dosator then compresses the captured powder. This compressing process creates a consistent density for accurate dosing.

Once the powder is compressed, the meter retracts and the compressed powder plug is withdrawn from the tube. The machine then places the powder plug precisely over the open capsule body.

The capsule filling machine's conveyor mechanism then loads the compressed powder into the open capsule body. The filled capsules remain inside the machine and then go through a series of processes, such as cleaning. Finally, the capsule bodies are joined up, which results in a perfect finished capsule.

What is Tamping Pin Capsule Filling Machine?

A tamping pin capsule filling machine, sometimes also called a dosing disc capsule filler, is a large machine for filling powders into capsules. Its core dosing and filling device is a dosing disc with a tamping pin, which is different from the dosator capsule filler we discussed earlier.

The dosing disc is actually a rotating disc with multiple cavities on its surface. Each cavity is a pre-measured chamber that holds a specific amount of powder.

How Does a Tamping Pin Capsule Filling Machine Work?

Similar to the dosator capsule filling machine, the first step of the machine's operation is also pouring empty capsules into the capsule hopper. As the dosing disc rotates, it passes through a large hopper filled with powder. This hopper acts as a huge reservoir, constantly feeding the powder into the cavities of the disc. By gravity, these cavities will be fully filled with powder.

As the dosing disc continues to rotate, the tamping pin descends and compresses the powder in each cavity. This ensures consistent density and minimizes air pockets for accurate dosing.

Once filled, the powder cavities move to a work station where the tamping pins come into play. These tamping pins move up and down in a simultaneous way. When a cavity reaches this station, the matching tamping pin drops down and presses the powder inside the cavity.

After tamping, the dosing disc continues to rotate, delivering the filled and compacted cavity to the transfer station. Finally, the machine brings the top and bottom of the capsule body together, and that's the entire workflow of the tamping pin capsule filling machine.

What Are the Differences Between Dosator Type and Tamping Pin Capsule Filling Machine?

Complexity & Maintenance Requirements

Dosator capsule filling machines are more complex in design and typically have more moving parts. This can lead to higher maintenance requirements than needle tamping machines.

Tamping pin capsule fillers are simpler in design and have fewer moving parts. This usually means lower maintenance requirements.

Cost

The initial cost of a dosator filling machine may be higher because its design is more complex and requires higher quality materials for consistent capsule filling.

Whereas simpler designs and potentially fewer functions make tamping pin filling machines a more affordable option.

Applications

Dosator capsule filling machines are suitable for applications requiring high precision. These machines can handle various powders, even those with poor flow properties. So, they have become very popular in the pharmaceutical and nutraceutical industries.

However, tamping pin filling machines work better with powders that flow well, but perhaps not suitable for applications that need very high dosing accuracy. They are commonly used in the food and cosmetic industries.

How to Choose between Dosator Filling Machine and Dosing Disc Capsule Machine?

Below is a visual and simplified comparison to help you decide whether to use a dosator or a dosing disc (tamping pin) capsule filling machine.

| Feature | Dosator Filling Machine | Dosing Disc Capsule Machine |

| Dosing Mechanism | Compression with piston | Pre-defined cavities on rotating disc |

| Accuracy | High | Can be accurate, depends on powder flow |

| Powder Compatibility | Wide range | Best for good flow powders |

| Speed | Slower | Faster |

| Maintenance | Higher maintenance requirements | Lower maintenance needs |

| Cost | Potentially higher initial cost | More budget-friendly option |

| Cleaning | More thorough cleaning needed | Easier to clean |

| Fill Weight Adjust | Adjustable by compression stroke | Limited by pre-defined cavities |

| Noise Level | More noise | Lower noise level |

| Design Complexity | More Complex, more machine parts | Simpler, fewer machine parts |

At the end of the day, the best choice depends on your specific needs. Ask yourself

- How important is it to achieve extremely precise and consistent dosing?

- What types of powders do you need to handle?

- How important is production speed to your operation?

- What is the budget for your capsule filling machine?

- What resources do you have for machine maintenance?

By carefully considering these factors in the table above, we are confident that you will be able to select the machine that best combines accuracy, speed and efficiency for your capsule manufacturing business.