As popular machines in manufacturing, IBC bin blenders are widely used in various areas, such as pharma, cosmetics and chemicals. They can mix different ingredients evenly. If you want to invest in this equipment, there are something necessary you should know.

What is an IBC bin blender?

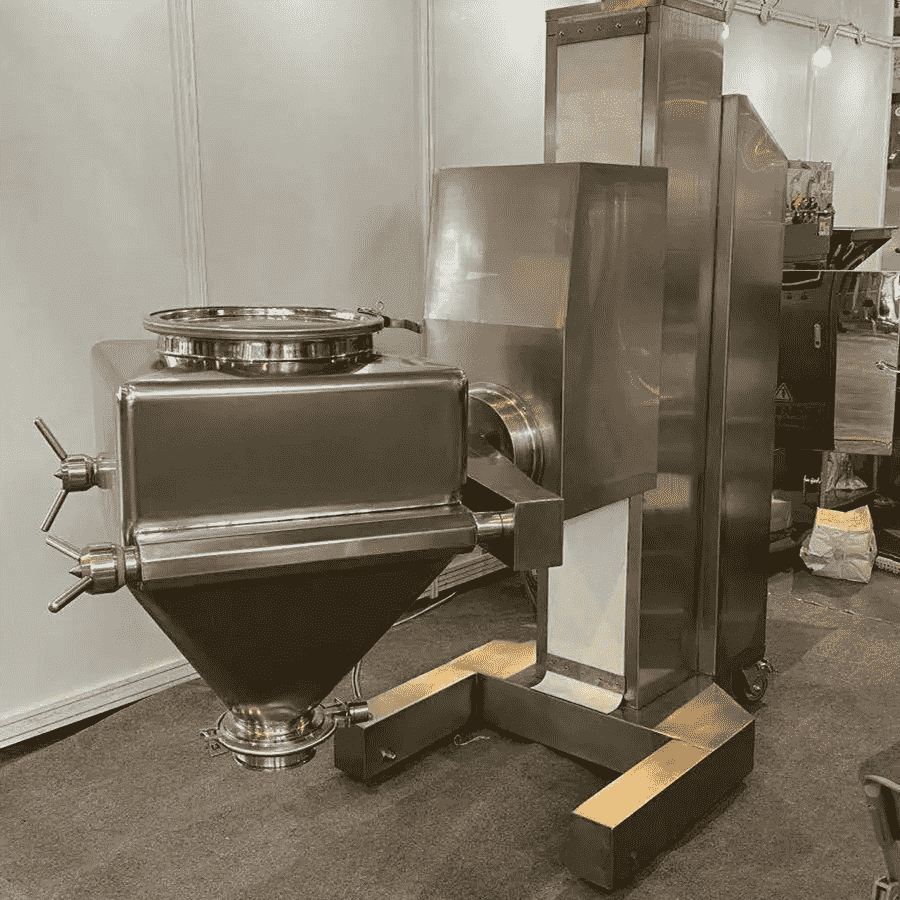

This names comes from an intermediate bulk container (IBC) the machine is equipped with. It is a detachable bin, and it is usually cube-shaped. During mixing, the bin spins and moves in different directions to make sure everything mixes well. Manufacturers use this machine a lot in factories, especially to make medicines, food or chemicals. It is good for handling large amounts of materials.

This machine also features an easy operation. Workers can take the bin off the machine to fill it or empty it easily. This makes the process faster and less messy. IBC bin blenders are made to prevent dust from spilling out. The bin could be closed tightly during operation. It is important for keeping the work area clean and safe.

Applications

IBC bin blenders have many applications in different industries. You can look at some examples.

- Pharma. They are used to mix powders for making tablets and capsules. In this way, all ingredients, like active drugs and fillers, are evenly mixed.

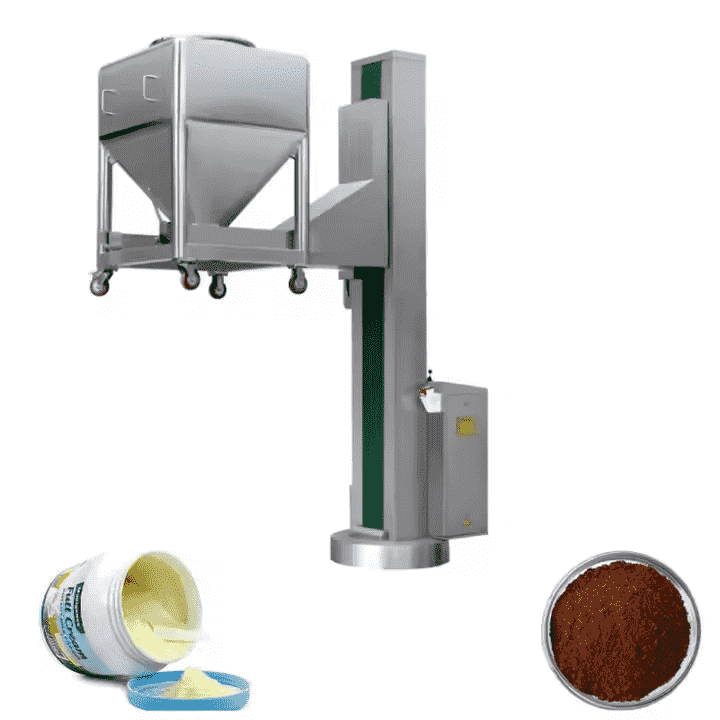

- Food. They help mix flour, sugar, and spices to make foods or seasonings.

- Chemical industry. They are used in mixing chemicals, pigments, or powders for paints, plastics, and cleaning products.

- Cosmetics. They are usually for makeup, skincare powders, or bath salts.

Five key parts of an IBC bin blender

IBC container

This is the most important part in the blender. The container is typically made from stainless steel. This material is not rusted easily. It also makes sure the ingredients inside are not contaminated. IBC containers are always designed with smooth inner surfaces to prevent material buildup. Moreover, this makes cleaning easier. When you use the IBC, it should be properly sealed to avoid leakage. Also, the container should be correctly attached to the machine for smooth rotation.

Rotating holder

The rotating arm holds the IBC container and rotates it to mix the product. Materials to make them should be durable, like stainless steel. Because they need to support the weight of the container and withstand strong motion. Operators should check that the arm is securely locked to the container before starting.

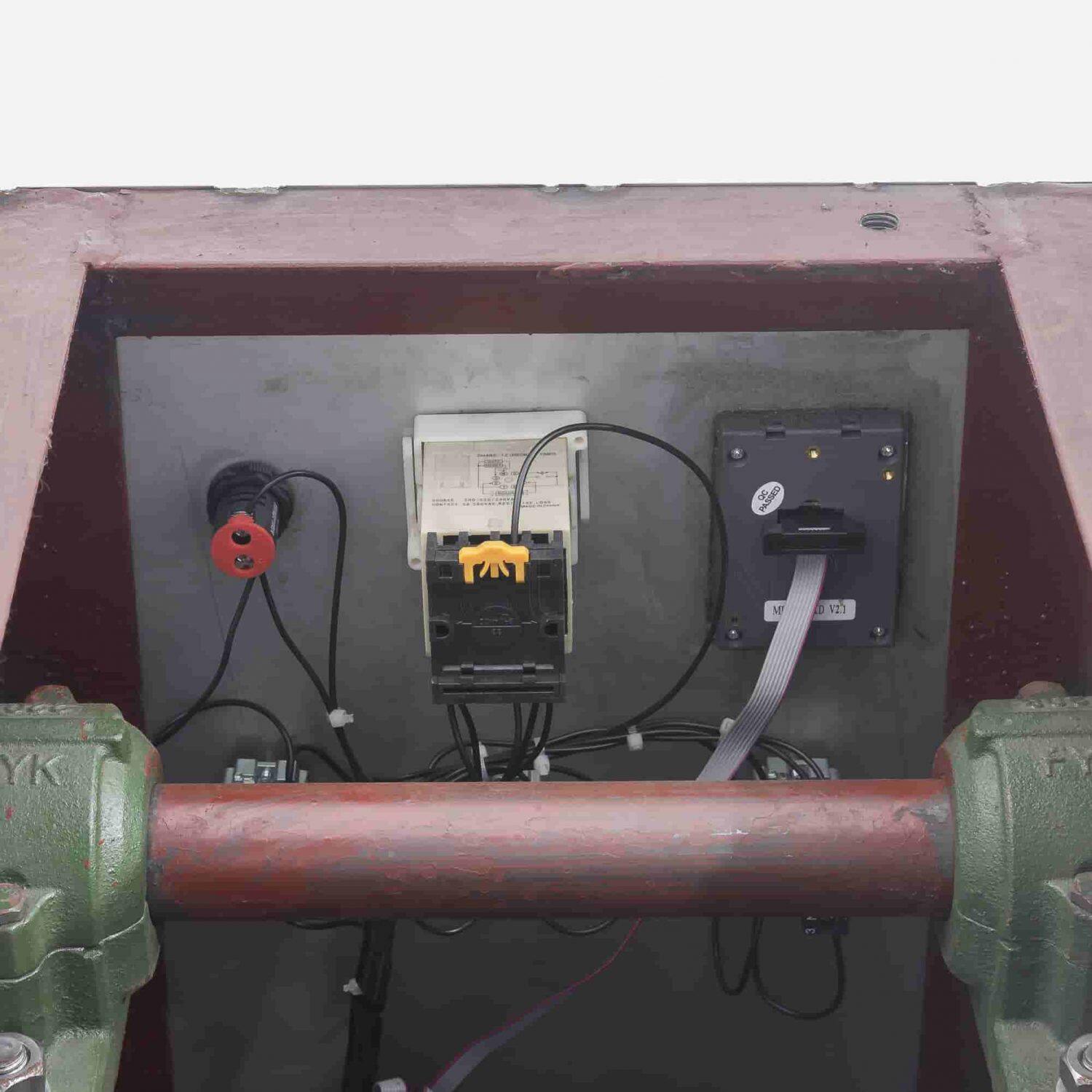

Control system

The control system allows operators to set parameters for the blending process. You can adjust speed, mixing angle, and duration. It is a vital component for precise mixing. Most control systems have a touchscreen for settings. Before operation, you’d better check that the control system is calibrated correctly. Regular updates and inspections are also necessary to maintain smooth production.

Support frame

The support frame forms the backbone of the IBC bin blender. It offers the rotating mechanism and the container support. Some frames include safety measures, such as sensors to detect improper positioning. When using, you should ensure the frame is placed on a flat place. Meanwhile, all bolts and joints are connected tightly. This can prevent instability during blending.

Drive system

The drive system includes the motor and gearbox. It powers the rotation of the container. The motor is usually an electric type. It has a protective casing to prevent damage from dust or moisture. The gearbox is made of hardened steel to withstand wear. Proper maintenance is critical. You need to conduct regular lubrication and part check. If some wear out, replace them in time.

How do you operate an IBC bin blender?

Load the products

At the beginning, you should put the ingredients into the container. The bin can be detached for easy filling. Please note that the container is sealed properly after loading.

Secure the bin

Once the bin is filled, it is placed upon the blender’s rotating arm. At this stage, you need to check that the bin is properly locked. So it won’t fall during mixing.

Setting

Then you can set the blending procedures, such as speed and angle. These settings depend on the type of materials and the desired uniformity. Accurate setting can avoid over-mixing or under-mixing.

Blending

The machine begins rotating the bin to mix the contents thoroughly. The rotation causes the materials to tumble within the bin. For some models, multi-directional movement like rocking enhances the mixing efficiency.

Unload the mixture

When the set time arrives, the machine stops. You can take the bin off the blender. The mixed materials are then unloaded. In this step, please note that no residue is left. So the next batch won’t cause cross-contamination.

Conclusion

IBC bin blenders are a great choice for people who require good mixing. They don’t need a lot of manual effort. They keep your mixing process clean and effortless. When finding suppliers, you’d better choose several ones at the same time. Then you can compare their machine price, quality and service to get the best one.