Moringa powder comes from the leaves of the Moringa oleifera tree. The leaves are harvested, dried, and ground into a fine green powder. This powder contains rich nutritional content. This includes high levels of vitamins A, C, and E to support immune function and skin health. It is also rich in iron and calcium. This helps energy production and bone strength. Besides these health benefits, moringa powder includes other nutrients like amino acids, antioxidants, etc. Due to its nutritional value, moringa powder is widely used in the supplement industry. So, moringa packaging is highly concerned about this business. If you want to pack this powder, you should know

- Benefits of proper packing for moringa powder

- Five common packaging materials for moringa powder

- Five popular packing machines to fill this powder

Why Do You Need Proper Packing for Moringa Powder?

Moringa powder is hygroscopic, so it easily absorbs moisture from the air. If exposed to humidity, it can clump together, and develop mold. Thus, proper packaging with airtight seals is needed to prevent moisture damage. In addition, light and oxygen can degrade the vitamins and antioxidants in moringa powder. They would reduce its nutritional value. Good packaging can block light and minimize air exposure. It helps maintain the powder’s effectiveness.

Moreover, food safety regulations pose requirements for powder packaging. The packing must include essential details such as ingredient list, expiration date, batch number, and nutritional facts. It is helpful for safe transportation and consumption.

Five Common Packaging Materials for Moringa Powder

Moringa powder is always packed in various bags, bottles and jars. They could be made of different materials for use. Here are common examples.

Plastic

Plastic is one of the most commonly used materials for moringa powder packaging. It includes many types, such as food-grade PET, HDPE, PP, etc. These plastics offer many advantages. They are durable and light. It makes them cost-effective for transportation and storage. More importantly, plastics offer strong protection against moisture and air. It is preferred by lots of moringa powder suppliers. Many plastic jars and resealable pouches use these materials due to their easy affordability and flexibility.

Aluminum foil

Aluminum foil is mainly made for various pouches, such as stand-up pouches, sachets, etc. It offers excellent protection against the environment to keep powders fresh. This material has a strong barrier that prevents oxidation. Aluminum is commonly used for vacuum-sealed or nitrogen-flushed packaging. This greatly extends shelf life. Despite their protective benefits, aluminum pouches are less eco-friendly and may not be biodegradable.

Glass

The main advantage of glass is its transparency. It allows customers to directly see the powders inside. They can find the color and powder size to see if it meets their demands. Glass packaging also gives a high-end appearance. So glass jars and bottles are commonly used for premium moringa powder packaging. In addition, glass won’t react with the product. It provides excellent protection from air and moisture. But glass is heavier than plastic and more fragile. This increases transportation costs and the risk of breakage.

Kraft paper

If you are looking for sustainable options for your products, kraft paper packaging is a good choice. Since kraft paper itself does not provide airtight sealing, it is often combined with an inner plastic or biodegradable lining to maintain freshness. It gives a natural and organic look. This appeals to environmentally conscious consumers. They always select the environmentally friendly product as the first choice. However, kraft paper may not be as durable as plastic or aluminum. Also, it is not so good when protecting powders against humidity and pests.

Biodegradable and compostable materials

As sustainability becomes more important, biodegradable and compostable packaging materials are increasingly popular. These materials include plant-based plastics, compostable cellulose films, and bio-coated paper. They offer similar protection as traditional packaging while reducing environmental impact. However, biodegradable options may have a shorter shelf life compared to plastic and aluminum. They require more careful storage.

Five Popular Types of Powder Filling Machines for Moringa Powder

Good packing requires a high-quality filling machine to complete. It packs moringa powder efficiently and accurately. There are many types of powder filling machines available on the market. You can select the best one based on your production needs, packaging type, and budget.

Auger filling machine

An auger filling machine is one of the most common types used for fine powders. It uses a rotating screw to dispense powder. Auger fillers are known for their high accuracy. They are ideal for filling jars, pouches, or sachets. The machine can be semi-automatic, or fully automatic. Fully automatic models work without manual input and feature high efficiency. But it is the most expensive model.

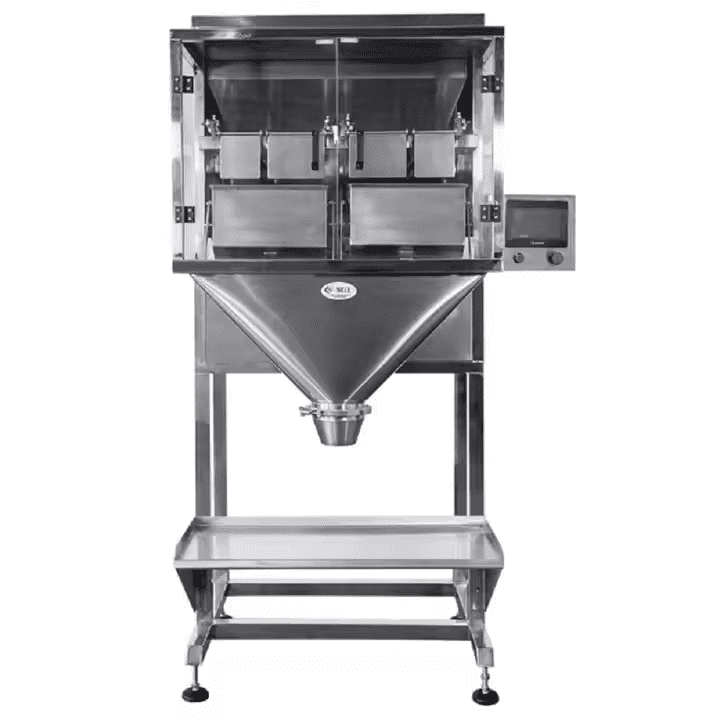

Vibratory filling machine

This type uses vibrations to control the flow of moringa powder into containers. It is suitable for powders that do not flow easily. Vibratory fillers ensure an even distribution of powder and reduce clumping. They are often used for bulk packaging. If you fill powders into rigid containers like glass or plastic jars, it is also a good choice.

Gravity powder filler

Gravity-based powder filling machines rely on the natural flow of powder to fill containers. They work best with powders that have good flow properties. Because of easy operation and cost-effectiveness, gravity fillers are popular in the market. But they are not ideal for large-scale production, much better for basic or small-scale businesses.

Vacuum powder filling machine

Vacuum powder filling machines use suction to pull moringa powder into containers. This method is useful for very fine or light powders that might create dust during filling. The vacuum system helps keep the work area clean and prevents powder loss. These machines are often used for high-quality, dust-free packaging.

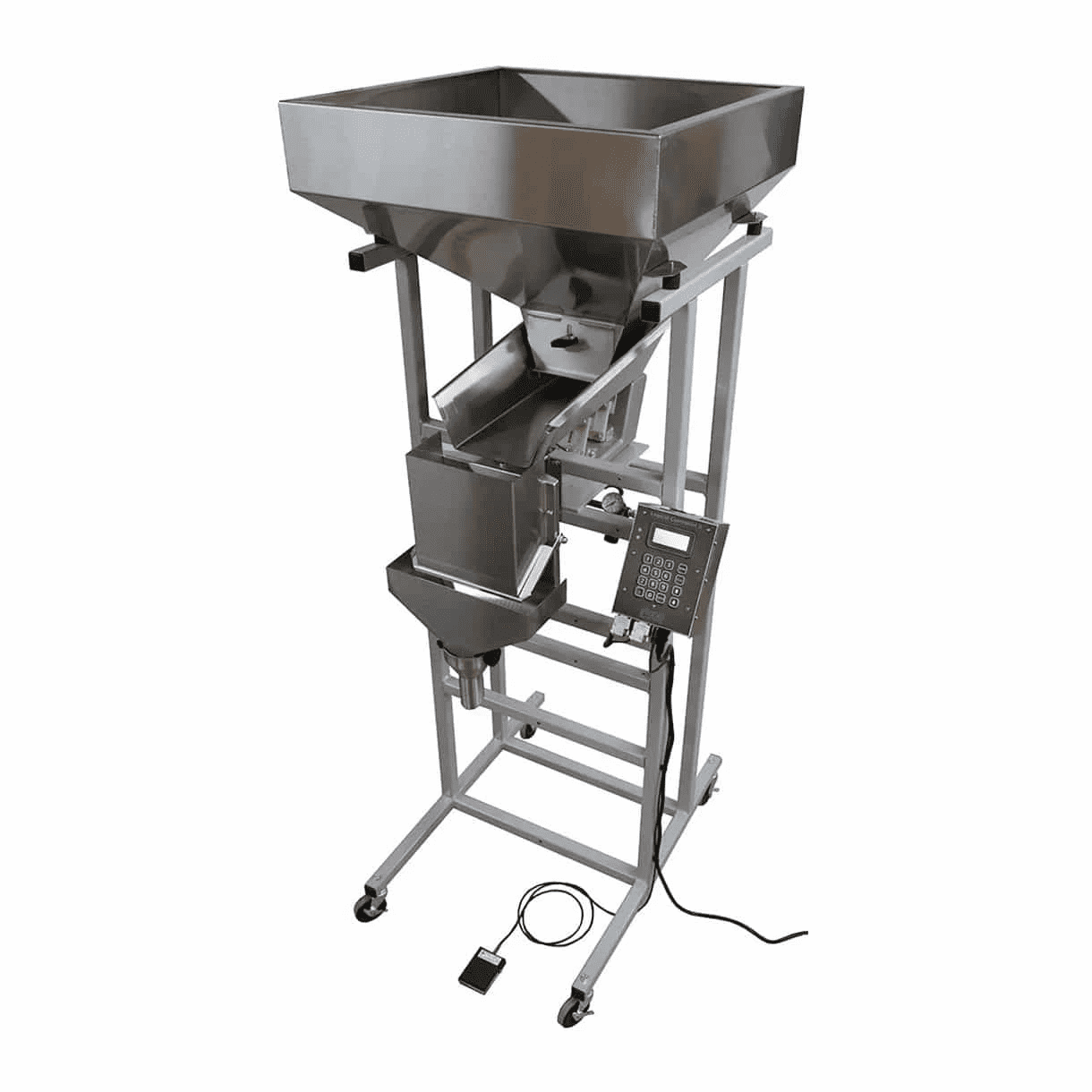

Net weight powder filling machine

This model uses a weighing system to measure the exact weight of moringa powder. It is ideal for products that must meet strict weight requirements. This machine is commonly used for bulk packaging or premium moringa powder products.

The End

There are many ways to pack moringa powder. With a wide selection of materials, you need to choose the most suitable one according to your brand. If you need powder filling machines, feel free to contact HUADA Pharma. We offer various liquid fillers to meet your needs.