More and more clients are starting to purchase semi-automatic capsule filling machines for their pharmaceutical businesses. They offer a middle ground between fully manual and fully automated processes, making them ideal for small businesses seeking high efficiency with good prices.

If you are interested in this machine, it’s important to know what it is and which parts are super important for it to work well. Now let’s have a look.

What is a Semi-Automatic Capsule Filler?

A semi-automatic capsule machine is a device employed in pharmaceutical manufacturing to fill capsules. It helps fill empty capsules with powdered or granulated medication. In contrast to fully automatic capsule fillers, which handle all tasks independently, semi-automatic machines involve some manual intervention.

This type of machine is great for small to medium-scale businesses that don't require high-volume production but need automation.

Important Parts of a Semi-Automatic Capsule Machine

Now, let's look at the important parts of a semi-automatic capsule machine. Understanding these pieces will help you gain valuable insight into purchase options or optimizing the machine's performance for pharmaceutical applications.

Powder Hopper

It is used to store powdered materials, such as medication or supplements, before dispensing. The hopper is always designed with an inlet on the side, allowing the operator to refill powders easily. After the materials are filled, they will be evenly distributed onto all capsule bodies in the tray.

Capsule Hopper

It serves as a receptacle for storing the capsules awaiting filling. Above the hopper, there is often an enclosed part to keep the dust from entering. The capsule hopper comes in many shapes, such as cylindrical, conical, wedge shapes, etc. Moreover, the hopper allows for regulating the quantity of empty capsules dispensed simultaneously.

Capsule Sowing Mmechanism

This is the core component of semi-automatic capsule fillers. It comprises a fully assembled magazine, a sorting block, and horizontal sorting fingers. Positioned beneath the capsule hopper, it receives empty capsules and allows for the adjustment of their orientation to align with the holes in the filling tray. Then, at your specified speed, the empty capsules are filled into each respective hole.

Filling Tray

It's a component structured with numerous slots intended for holding empty capsules to be filled. It consists of two discs, capable of holding capsule caps and bodies when separated. Typically, manual intervention is required for the separation process.

The filling tray guarantees that the capsules are firmly secured and correctly positioned for the filling process. Filling trays come in various designs and configurations to accommodate different types and sizes of capsules.

Filling Head

It's a critical part of the machine, typically designed in a nozzle shape. Its primary function is to accurately dispense the medication powder or granules into the empty capsules, ensuring precise dosing and uniform filling.

First, it has to line up with the openings of the empty capsules in the tray. Then, it puts the right amount of filling stuff into them. During this process, both the filling amount and speed can be adjusted.

Control Panel

The control panel is the brain of a semi-automatic capsule filling machine. It usually includes an HMI touch screen and a series of buttons and switches.

It allows operators to control and monitor the filling process based on specific production needs, such as changing the filling speed, seeing how the filling is going, etc.

Vacuum System

A vacuum pump sucks air out of a closed area to change the pressure inside. In a semi-automatic capsule filler, a vacuum is used to split apart the capsules. You can adjust how strong the vacuum is to make sure all the capsules separate properly.

If you're having trouble with capsules sticking together or flying off during production, your vacuum pump might be the culprit.

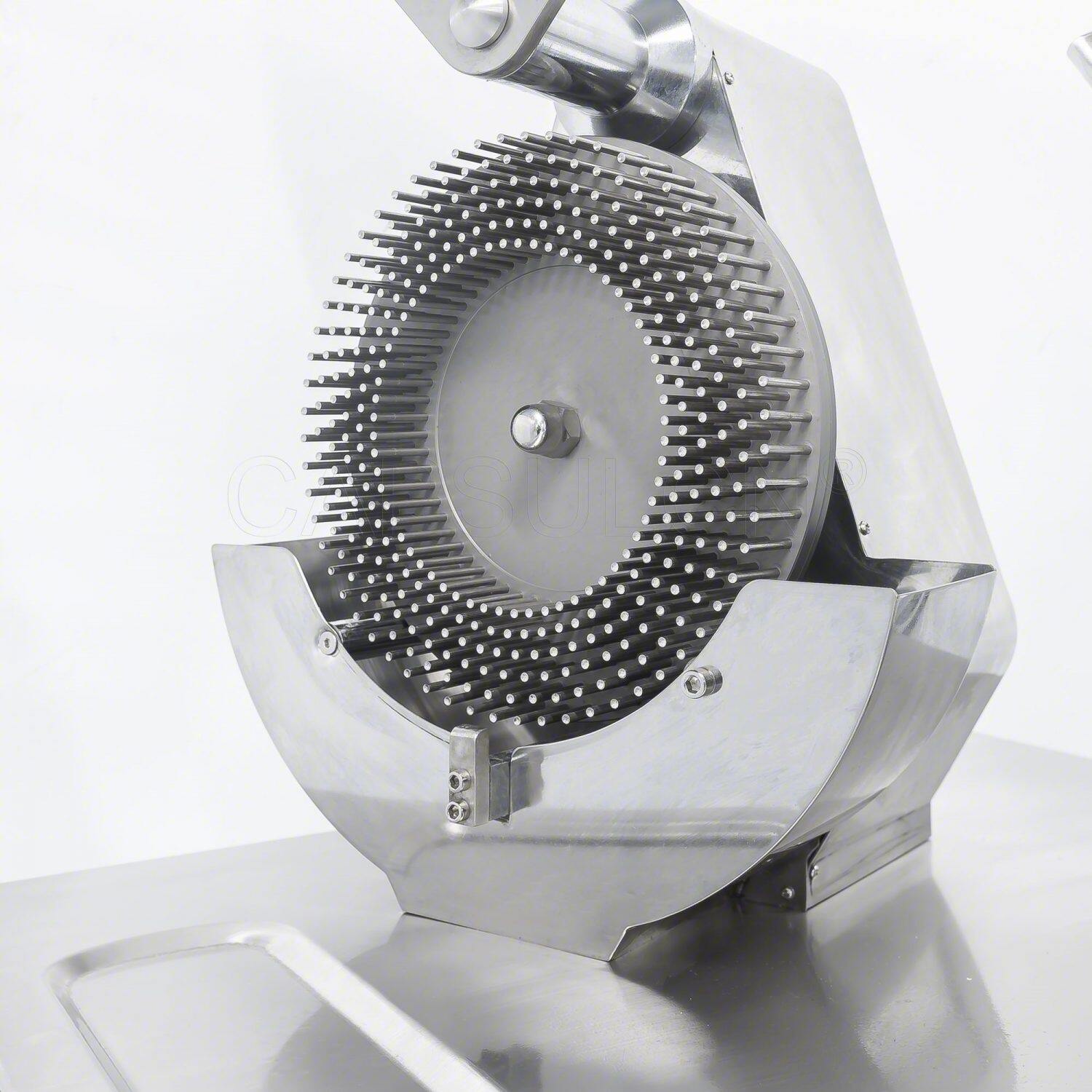

Capsule Closing Mechanism

This mechanism helps lock the two halves of the filled capsule. In this part, the peg ring is the core tool. It comes in a disc shape with multiple pins. After filling the capsules, the worker puts the tops and bottoms back together. Then he puts the whole filling tray on the peg ring, ensuring the ejector pins are inserted into the holes of the filling tray.

To start the closing process, pull the top cover onto the capsule tray first. Some models do it automatically, others need manual closing. Then the peg ring is pressed against the filling ring to seal the filled capsules.

Discharge Outlet

After the filled capsules are closed, they get pushed out of the tray and blown into the outlet, then fall into a collection box. You can choose the shape of the outlet. Usually, it's like a drawer. If you want something specific, just ask your supplier to make it for you.

Safety Guards

Safety guards are protective mechanisms or devices installed on machinery to prevent accidents or injuries to operators or other personnel. They mainly include physical barriers, shields, or interlocking mechanisms.

These parts are designed to prevent the operator from touching moving stuff, such as the filling mechanism or capsule ejection system, thereby reducing the risk of accidental contact. At the same time, they can also contain any fragments that may occur during the filling process, preventing them from splashing into the air and causing injury to operators.

In addition, there is an emergency stop. You can press it when finding that the machine doesn’t work well as required. Once you press it, the operation will stop.

Wrap-Up

I hope this article can help you have a thorough understanding of the key parts of a semi-auto capsule filling machine and make a wise choice when purchasing your machine.

At HUADA Pharma, we offer a wide selection of high-quality capsule fillers to meet your needs. Our machines are meticulously crafted for efficiency, precision, and user-friendliness. And we also have a professional team committed to delivering top-tier assistance to our valued customers. If you have any questions, feel free to contact us.