Picture this: you strive to create a perfect batch of tablets, pouring your expertise and hard work into each one, yet a small part of the tablet material clings to the tablet press, or a portion of the batch suffers from annoying imperfections.

In this blog post, we'll delve into the world of tableting to unravel the secrets behind tablet sticking and picking problems. Whether you're an experienced manufacturer or just starting out, you'll find valuable insights and practical remedies here to turn that sticky mess into a flawless tablet. Let's get started!

What's the Difference Between Sticking and Picking of Tablets?

Sticking and picking are both common tablet defects. They involve tablet material adhering to the faces of the compression tooling. Yet, these two tablet defects slightly differ regarding where they occur during tablet manufacture.

Here are the main differences between sticking and picking in tablets.

| Sticking | Picking | |

| Definition | Adhesion of powders from the tablet formulation to the punch tip face. | A specific type of sticking. It occurs when the granules get stuck on the punch tip faces with embossing designs. |

| Cause | Typically caused by high moisture content, insufficient lubrication, or formulation or machine-related issues. | In addition to the causes of sticking, the embossing designs on punch tips can also result in picking. |

| Location | Generally occurs on the punch tip face, where the powders or granules come into contact with the tooling. | Specifically occurs on the faces of the compression tooling where the embossing designs are located. |

What is Sticking in Tablet?

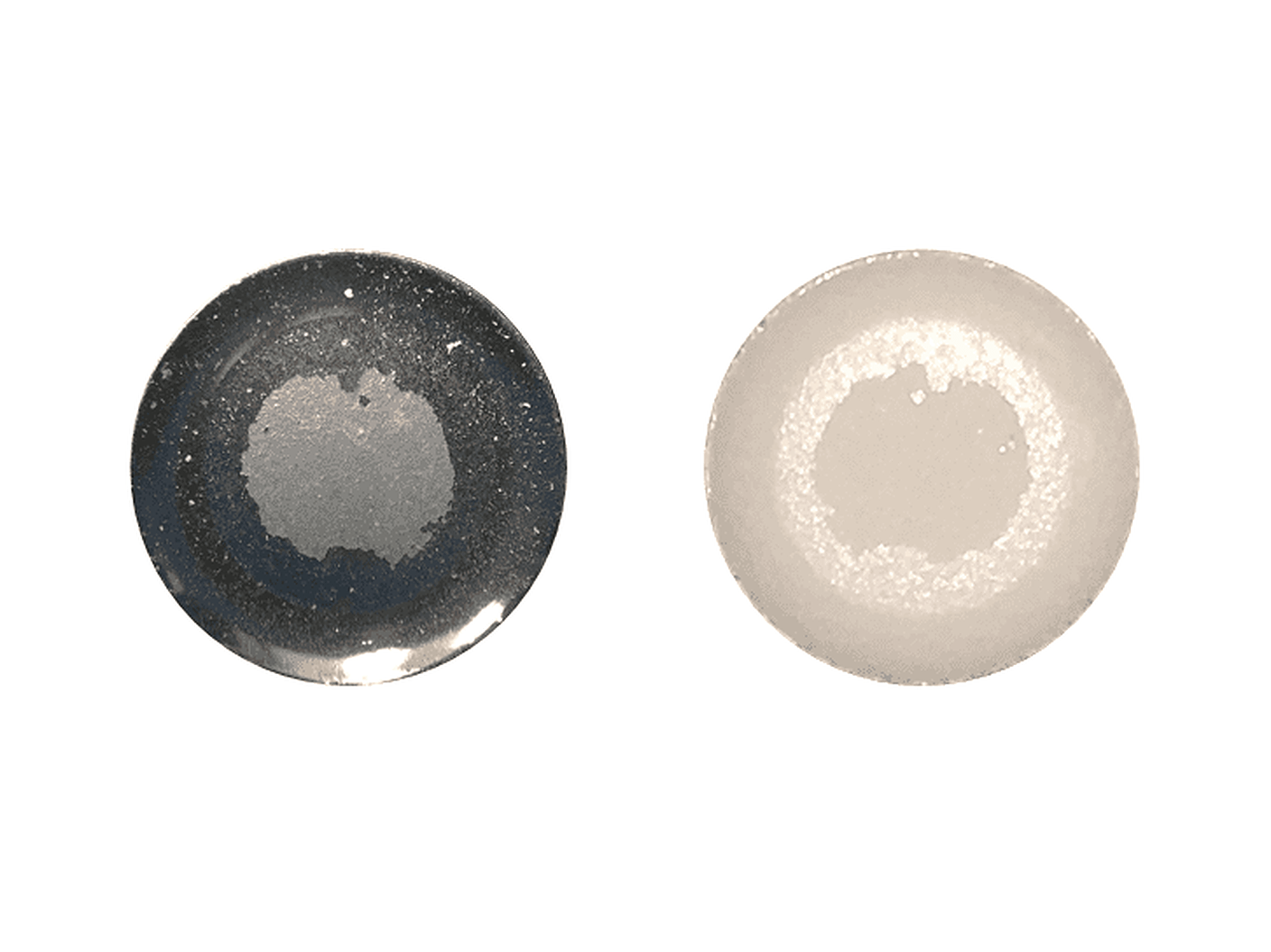

Sticking tablets problem is very common. It occurs when the tablet material comes in contact with the punch tip faces and die wall during compression. This can result in a small portion of the tablet remaining attached to the punch tip face as it withdraws from the tablet surface. This can be effectively avoided by using reasonable raw equipment. We will show you about sticking tablet defects and remedies.

Causes of Tablet Sticking Problem

The sticking problem in tablets can be attributed to several causes. Understanding these causes helps effectively tackle the issue. Let's look at the common causes of tablet sticking.

- High Moisture Content. Due to inadequate drying of granules, excessive moisture in the formulation can cause the tablet material to clump together and adhere to the punch tip.

- Insufficient Lubrication. Inadequate lubrication or improper selection of lubricants can affect the smooth movement of the granules during compaction.

- Formulation-Related Issues. Some tablet formulation problems can also cause sticking. For example, hygroscopic ingredients can increase the moisture content in the formulation.

- Compression Force and Speed. Improper compression force or speed can force the granules to adhere to the punch tip.

- Tooling Design. Deep concave punches can increase the chance of the adhesion of powders to the punch tip face.

Impacts of Sticking Problem in Tablets

The tablet sticking problem can lead to various issues that affect the quality and appearance of the tablets. Here are some details on the impacts of these tablet defects:

- Rough Surfaces. Sticking can result in rough surfaces on the tablets. This will make your tablets aesthetically undesirable to consumers.

- Film Formation. Sticking can lead to the formation of a thin film on the punch tip face. This film can affect the batch-to-batch consistency of your tablets.

- Inconsistent Weight or Dosage. Sticking can also cause variations in the weight or dosage of the tablets. This can affect product safety and effectiveness.

- Manufacturing Efficiency Challenges. Sticky tablets need to be identified and rejected during downstream stages. This can reduce manufacturing efficiency and increase production costs.

Tablet Sticking Problem Solution

To address the sticking problem in tablets, here are some detailed tablet sticking problem solutions:

- Sufficient Drying. Thoroughly dry the granules before compression in tablet press machines. Implement efficient drying methods to control the moisture content.

- Adequate Lubrication. Use appropriate lubricants and ensure the formulation is properly lubricated.

- Reformulation. Modify the formulation by replacing hygroscopic ingredients. Adjust the ratio of excipients to reduce moisture-related sticking issues.

- Compression Parameter Optimization. Adjust the compression force and speed. Determine the optimal parameters to ensure smooth tablet ejection.

- Tooling Design Optimization. Avoid using extra deep concave punches. Polish or coat the punch tip face if necessary.

What is Picking in Tablet?

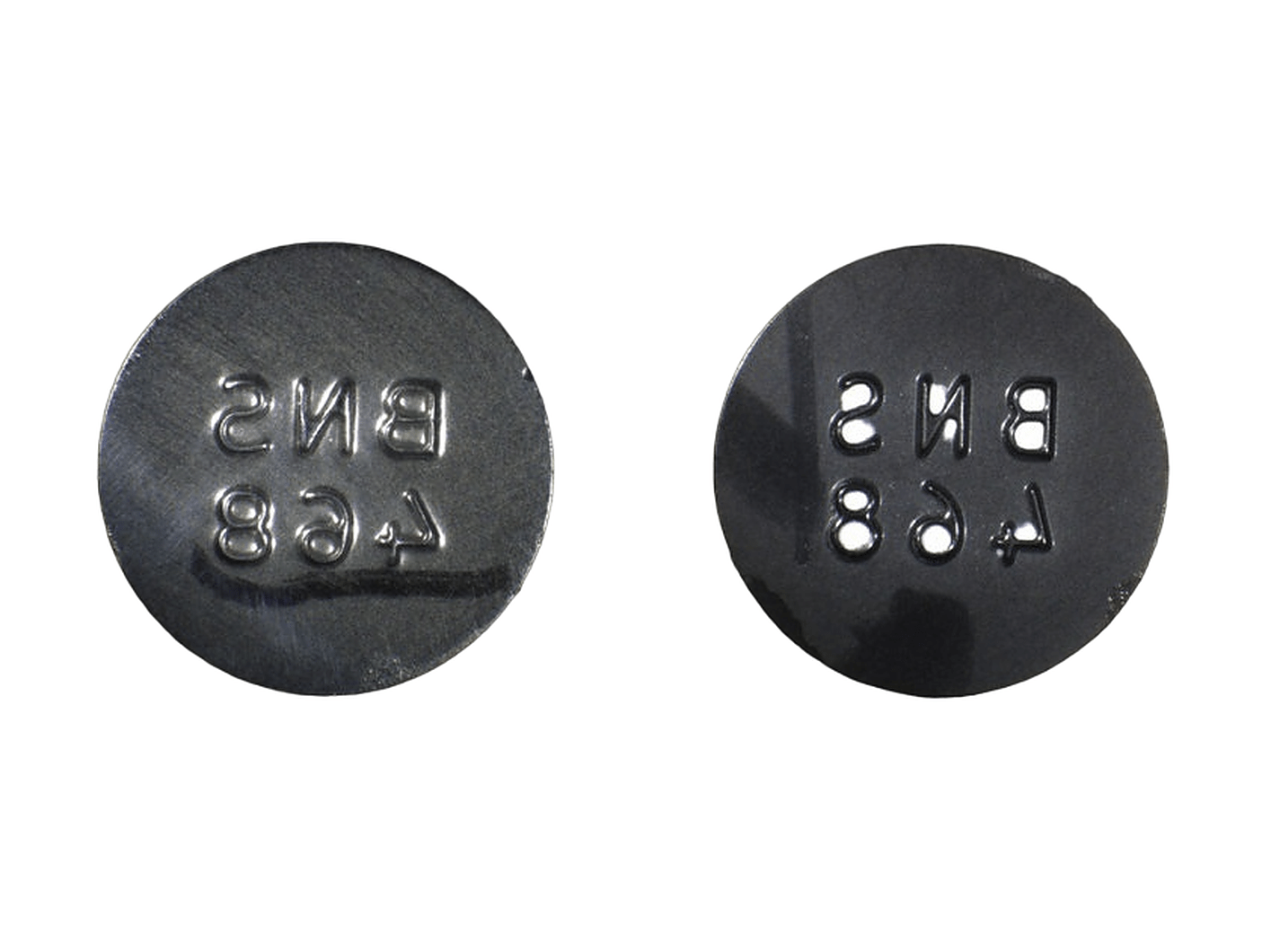

The picking problem in tablets is a visual phenomenon that occurs during tablet manufacturing. It is characterized by the sticking of the tablet formulation to the tablet embossing lettering or logos on the punch tip.

Causes of Picking in Tablets

Here are several causes that can contribute to the picking problem in tablet manufacturing.

- Tablet Embossing Designs. The logos or identifiers on the embossing tablet surface can trap powders and hold them in the punch tip. This can lead to picking issues during tablet ejection.

- Formulation Properties. The ingredients with cohesive nature can make the formulation more prone to picking. And the tablet material not well granulated is more likely to get trapped in the tablet embossing designs.

- Excessive Compression Force. Excessive compression force can cause the tablet material to stick to the tooling surfaces.

- Insufficient Lubrication. If the formulation and punches are not properly lubricated, the friction between them can be increased, leading to tablet material adhesion.

Impacts of Tablet Picking

Picking, as a specific type of sticking, can have significant impacts on your tablets. This tablet defects refers to the granular material getting stuck on the punch tip faces, primarily due to tablet embossing designs such as logos or identifiers. Here are several impacts of picking:

- Unappealing Appearance. Picking can result in a rough tablet surface, particularly where the logos or identifiers are located. It leaves the finished tablets with an imperfect look.

- Inconsistent Logo or Identifier. The material getting stuck on the tablet embossing designs can cause the tablet logo or identifier to be unevenly formed. This can impact the visual identity of the tablets and affect their branding.

- Compromised Quality. The final product quality cannot be guaranteed if tablets come with damaged logos or identifiers.

- Reduced Production Efficiency. Tablets with picking problems need to be identified and rejected during manufacturing. This can slow down production and result in increased costs.

Remedies for Picking of Tablets

Here are some helpful remedies for picking problem in tablets..

- Modification of Compression Tooling. Adjust the shape, size, or depth of the tablet embossing designs or polish the punch tips to prevent powders from trapping.

- Granulation and Formulation Optimization. Ensure complete granulation of the formulation to achieve uniform particle size and shape. Replace cohesive ingredients for better flow properties.

- Compression Parameter Adjustment. Adjust the compression force to an optimal level to ensure smooth tablet ejection.

- Lubrication Monitoring and Optimization. Use suitable lubricants and a lubrication monitoring system. Ensure proper lubrication of both the formulation and punches to reduce friction and adhesion.