Do you make tablets that need to be coated during production? Are you looking to buy or use tablet coating equipment? If that sounds like the case for you, then look no further - You have found exactly the right spot.

This guide offers all of the advice necessary for selecting an optimal tablet coating machine to meet your needs. It can provide greater insight into coating processes while answering any inquiries that come up along the way. And if you have any questions, we're here to answer them.

What Is a Tablet Coating Machine?

Tablet coating machines are versatile pieces of machinery. They are designed to apply a protective layer over various tablet formulations. They can do lots of different things. For example, protecting active ingredients from breaking down, making tablets look better by changing the color, protecting tablets from getting damaged by humidity or oxygen, and stopping tablets from decaying because of moisture or oxygen exposure.

What Are the Advantages of Tablet Coating Equipment?

Tablet coating machines provide numerous benefits in tablet production. Some advantages of such machines include:

- Superior Quality: This equipment ensures uniform coating application to deliver tablets free of defects such as chipping.

- Uniform Coating: Furthermore, each batch receives equal coating coverage across its entirety; shape and size alike by this equipment.

- Reduce Wastes: Wastage can be reduced dramatically through direct application of coating material; saving valuable substances that would otherwise go unused.

- Tablet Protection: Protective coating helps shield tablets during transportation and storage from being handled roughly or accidentally dropped onto hard surfaces.

- Tamper Proofing: Coating ensures tablets remain true-to-form for shape and size; making them both tamper evident and authenticating them.

What Industries Use Tablet Coating Machines?

Tablet coating equipment has numerous uses within numerous sectors.

Pharmaceutical Industry

This equipment is an indispensable asset in coating an extensive selection of pharmaceutical tablets, from film-coated and enteric-coated formulations. Coating enhances patient comfort and convenience by improving tablet taste and texture, which improves taste perception as well as patient convenience.

Food Industry

Tablet coating machines are widely utilized by the food and confectionery industries for coating various products like chocolates, chewing gums, candies, and toffees to preserve flavor while increasing shelf life as well as visual appeal of these items.

Nutraceutical Industry

Coating equipment is used to protect delicate nutraceuticals tablets by creating a protective shield that preserves product integrity and potency.

Chemical Industry

Coating can enhance chemical fertilizers and specialty tablets’ physical properties, release characteristics and resistance to environmental factors.

Cosmetics Industry

When it comes to coating cosmetic tablets for serums, wax beans or pedicure products, precise coating is required for product purity and efficacy as well as appearance enhancement and texture improvements. Coating can also enhance their aesthetic value and aesthetic value.

What Materials Are Commonly Used to Coat Tablets?

Tablet coating materials provide distinctive properties and applications.

Acrylic Polymers

Acrylic polymers such as polyvinylpyrrolidone and polyvinyl alcohol are frequently employed in both immediate-release and extended-release formulations. They can provide moisture protection, increase tablet strength, and help bind tablet powders more securely.

Hydroxypropyl Methylcellulose

Cellulose-based materials like hydroxypropyl methylcellulose make an ideal coating solution. Because of their moisture resistance and film-forming characteristics, they provide efficient yet cost-effective coating solutions.

Polymethacrylates

Polymethacrylates are known for their high permeance and water solubility properties. This makes them suitable for creating slow release coatings to delay drug release, thus minimizing interactions. They're often used when making slow-release capsules to slow down how quickly drugs are released into the body.

Wax

Waxes made from carnauba leaves give tablets an extra boost in appearance and environmental protection. They make them look better and help them stand up to external factors.

What Types of Tablet Coating Equipment Exist?

Tablet coating equipment can be divided into various categories depending on its operating principles and pressure capabilities. The primary types include:

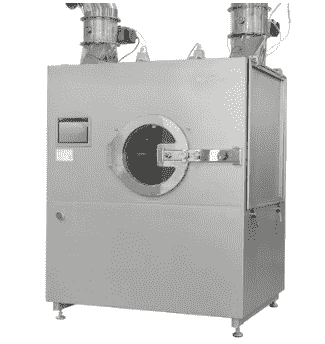

Standard Coating Equipment

- Pellegrini Tablet Coating Equipment - Uses a baffled diffuser to evenly disperse hot and warm air for consistent coating results, creating uniform conditions during coating processes.

- Immersion Sword Tablet Coating Equipment - Employs an overhead long sword to distribute heat into coating pan and accelerate coating processes faster.

- Immersion Tube Tablet Coating Equipment - Comes equipped with two immersion tubes that synchronize material and hot air supply, increasing coating efficiency.

Perforated Coating Equipment

- Dria Coater Pan - Utilises an inverted airflow system where exhaust air moves upward to facilitate precise coating of surfaces.

- AccelaCota System - Leverages a cocurrent airflow system where hot air enters from above while exhausted air exits below for efficient coating processes.

Fluidized Bed Coating Equipment

Image Source: UMANG

By employing fluidization principles to suspend tablets in an airbed and allow uniform coating, fluidized bed coating equipment provides uniform results.

Pressure-Based Coating Equipment

High-Pressure Tablet Coating Equipment - Intended to support large-scale production, these machines operate at high pressure to enable quick atomization and efficient coating processes.

Low-Pressure Tablet Coating Equipment - Perfect for small operations, these machines operate under lower pressure to allow a more precise coating process and increase accuracy and control.

What Are the Factors that Influence the Efficiency of Tablet Coating Process?

Tablet coating processes are affected by several factors.

- Coating materials: The quality and efficiency of coating processes depend on the coating material's viscosity and solubility. Proper material selection and mixing ensure uniform coating application without waste.

- Coating spray design: The design and size/shape of the spray nozzle affect how evenly the coating material is distributed over the tablet surface.

- Airflow capacity: Adequate airflow capacity is key to efficient solvent extraction and tablet drying.

- Spray speed: Maintaining consistent spray speeds ensures that each tablet receives just enough coating material.

How to Keep Optimal Tablet Coating Equipment Performance?

To keep your tablet coating equipment in good shape, have a good maintenance plan. This includes:

- Schedule regular lubrication. Lubricating moving parts helps cut down on friction and wear, which can lead to downtime and extend the lifespan of your equipment.

- Cleanliness is key! Clean equipment after each production run, including the coating pan, spray nozzles, and internal components. This helps keep the product safe and the equipment working well.

- Here's how to take care of your spray gun. Inspect, clean, and calibrate your spray equipment regularly to keep your spray patterns consistent and prevent clogging.

- Control systems must be calibrated correctly. The temperature, pressure, and flow rate sensors must be accurate to control coating processes and produce a high-quality product with less waste. We also need to make sure the sensors are calibrated regularly.

- Preventive maintenance. Set up a schedule for preventive maintenance that includes regular inspections, component replacements, and functional tests. This helps us identify potential issues before they become serious problems.

Final Thoughts

There are lots of different coatings that can be used on tablets. These coatings can make tablets stronger, more durable, and look nicer. When buying coating equipment, understand how it works and what equipment is available. HUADA Pharma is here to help, so feel free to reach out to them with any questions or for assistance.