Are you facing unexpected troubles with your tablet counting machine? It's a common challenge, particularly when working with semi-automatic or fully automatic equipment. While these automated wonders can be very beneficial, they can equally become a source of frustration when they decide to act up.

This informative blog will delve into the common machine problems that can pop up out of nowhere. Also, we're going to provide you with practical, effective solutions. So, if you're ready to resolve those pesky tablet counting machine issues, don't hesitate to continue reading!

How to Troubleshoot a Pill Counter Machine

Based on their designs and working principles, tablet counting machines can be categorized into three types:

- Manual

- Semi-automatic

- Fully automatic

The first is the simplest hand-operated type, while the last two are automated devices with a relatively intricate structure. That's why unexpected problems may crop up when using these machines.

Common Semi-Automatic Tablet Counting Machine Problems and Solutions

| Problem | Possible Cause | Solution |

| Low Counting Accuracy | The glass window on the top surface of the photodiode is covered in dust. | Blow away any dust or gently wipe the window with a damp tissue. |

| The infrared emitter is covered in dust. | Blow away any dust or gently wipe the window with a damp tissue. | |

| The turntable spins too fast. | Adjust the turntable speed based on the diameter of the pills to be counted. | |

| The turntable is overfilled with pills to be counted. | Reduce vibration frequency. | |

| Abnormal Noise | The material feed gate is loose. | Adjust and fasten the feed gate. |

| Broken pills are stuck in the turntable. | Clear the broken tablets in the gap of the turntable. | |

| The vibrator is not aligned properly. | Reinstall the vibrator. | |

| Vibrator Not Working | The electrical box is overloaded, or the fuse blows. | Unplug unnecessary appliances or replace the fuse. |

| The vibrator is damaged. | Replace the vibrator. | |

| Turntable Not Rotating | The electrical box is overloaded, or the fuse blows. | Unplug unnecessary appliances or replace the fuse. |

| The motor speed controller is damaged. | Replace the damaged speed controller. | |

| The motor is damaged. | Replace the motor. | |

| LED Display Not Working | The electrical box is overloaded, or the fuse blows. | Unplug unnecessary appliances or replace the fuse. |

| The transformer is damaged | Replace the transformer. | |

| The CPU on the circuit board is damaged. | Replace the CPU. | |

| Counts Setting on the LED Display Not Working | The keypad is broken. | Repair or replace the keypad. |

| The CPU on the circuit board is damaged. | Replace the CPU. |

Common Automatic Tablet Counting Machine Problems and Solutions

| Problem | Possible Cause | Solution |

| Pill Jamming | Pill feeding is too fast. | Adjust the position of the feed gate at the bottom of the hopper and the vibration frequency of the vibratory plates. |

| 2. The guiding channel is not compatible with pill sizes or shapes. | Replace with guiding channels suitable for the pills to be counted. | |

| Inaccurate Bottle Release | 1. The bottle neck finish is not aligned with the funnel opening. | Adjust the funnel position. |

| Bottle Filling Error | The guiding channel is not appropriate. | Replace the guiding channel. |

| 2. The feed gate or flaps are not in place or not working. | Check for pill jams or loose connections. | |

| 3. The counting sensor is not sensitive enough. | Adjust the counting sensor sensitivity. | |

| Alerts | 1. There are no bottles on the conveyor. | Load bottles. |

| 2. Bottles get jammed. | Remove any bottles blocking the conveyor. |

How to Use a Pill Counter Machine

Now that you have a rough idea of common tablet counting machine problems and their solutions, let's take a look at how to operate these machines properly.

STEP 1: Read the user manual carefully before use.

A good starting point for using a tablet counting machine should always be to read the instruction manual thoroughly. This step is crucial. It allows you to understand your machine's specific features, settings, and safety precautions.

STEP 2: Inspect the machine and perform calibration.

a. Clean the machine. Whether for first-time use or the next production run, ensure your tablet counting machine is clean. Keep contaminants or residues at bay. These foreign objects could impact counting accuracy.

b. Check for damage. Do a quick inspection of your machine's major parts and components each time. Check for any visible damage or wear. Ensure the machine is always kept in the best shape.

c. Conduct a calibration process. Any deviation may impact the counting accuracy. If you're a first-time user, be sure to follow the manufacturer's instructions to calibrate your machine strictly. After each use, don't skip the fine-tuning step either.

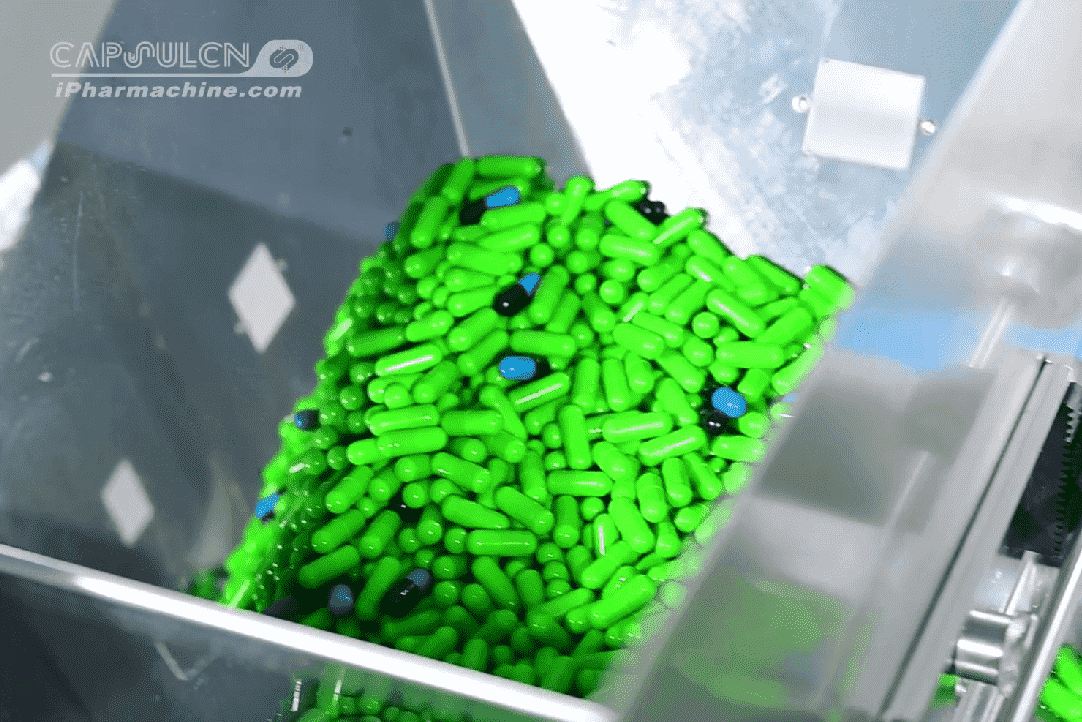

STEP 3: Prepare tablets or capsules to be counted.

a. Inspect the quality. Verify that the tablets or capsules you intend to count are intact. Check for any broken pills. Ensure they are consistent in size, shape, and weight.

b. Check for contamination. Ensure each pill is clean, without any foreign substances mixed in.

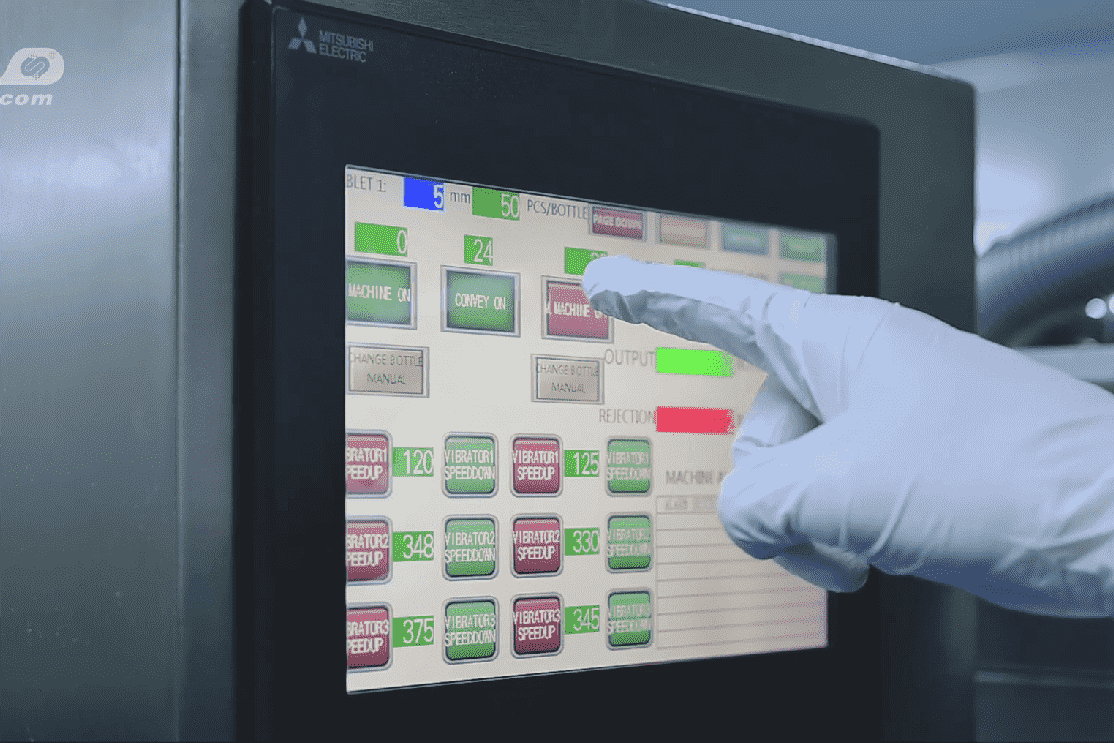

STEP 4: Set up production parameters.

a. Adjust counting speed. Set up the counting speed based on the machine's production capacity and the type of tablets you will be counting.

b. Set up batch quantity. Determine and set the desired output for each counting cycle.

STEP 5: Load tablets.

a. Load the tablets into the hopper. For semi-automatic machines, tablets need to be poured into the hopper by the operator. But if you're using an automatic tablet counting machine, you can feed the tablets into the machine using an automated loading device.

b. Monitor the loading process. Ensure tablets flow smoothly into the machine to prevent jams or irregular counting.

STEP 6: Commence the counting process.

a. Start the machine. Once all necessary parameters are set, press the START button to activate your tablet counting machine.

b. Monitor operation. Suppose you're using a semi-automatic pill counter. In that case, keeping a close eye on the machine as it counts the tablets is necessary. Automated machines are typically integrated with an alarm system to alert the operator to malfunctions.

STEP 7: Stop the machine.

a. Inspect the machine when each batch is complete. As soon as the preset batch quantity is reached, the machine will stop to avoid over-counting. Remember to do a walkaround inspection of the machine and get it ready for the next batch run.

STEP 8: Conduct cleaning and maintenance.

a. Clean the machine after use. Perform a regular cleaning after each use to prevent dust and residue buildup.

b. Perform scheduled maintenance. Adhere to the manufacturer's recommended maintenance schedule to keep the machine in optimal working condition.

Other Essential Procedures:

1. Safety precautions

Always prioritize safety by following established guidelines. Ensure that each operator uses the appropriate personal protective equipment (PPE) when operating the tablet counting machine.

2. Training

Ensure that anyone operating the tablet counting machine is adequately trained and understands its operation and safety procedures.