Tablet counting is a key step in production, especially in the pharma sector. Accurate counting ensures patients receive the correct dosage for the best effectiveness. Besides pharma, it is also applied in the food, supplement and cosmetics industries. So tablet counters are increasingly popular in the market. If you are interested in this equipment, you’d better know

- What is a tablet counter?

- What common types should you know?

- How to choose a good one for your business?

What is a Tablet Counter?

A tablet counting machine counts tablets or capsules in various industries, such as pharma. It fills each bottle with the desired number of pills according to the setting. It can also handle tablets of different shapes and sizes, including round, oval, or coated ones. Tablet counters ensure each package has the correct number of tablets. Compared to manual counting, it reduces errors and improves efficiency. Also, it helps build customers’ trust when they consume necessary pills.

Applications of Tablet Counters

Tablet counters have many applications in various industries. Here are some examples.

- Nutraceuticals. Manufacturers of dietary supplements, such as vitamins and minerals, use tablet counters to package capsules and tablets accurately. Supplements for beauty and pet care are also packed by this equipment.

- Food industry. Tablet counters are used to count small items like candies, mints, or chewing gum.

- Cosmetics. It always include products in capsule form, such as compressed facial mask tablets, fragrance tablets, etc.

- Agriculture. Some agricultural products, like seed tablets or plant nutrition capsules, are counted and packaged with this machine.

Five Common Types of Pill Counters

Manual Tablet Counters

Manual types are often used in small-scale businesses, like family workshops or drug stores. These machines are operated by hand in most steps. The operator needs to place the tablets on a tray with many holes. It depends on the number of holes to count pills. You can adjust the numbers and sizes of these holes to meet your production needs.

Manual pill counters feature easy operation and low cost. Even a newbie can operate it immediately to start production. However, the disadvantage is that they are time-consuming because of he limited speed. In addition, it is not efficient. The accuracy and quality of the final products is heavily dependent on the operator’s attention and skill. Here is a video to help you understanding.

Semi-Automatic Pill Counters

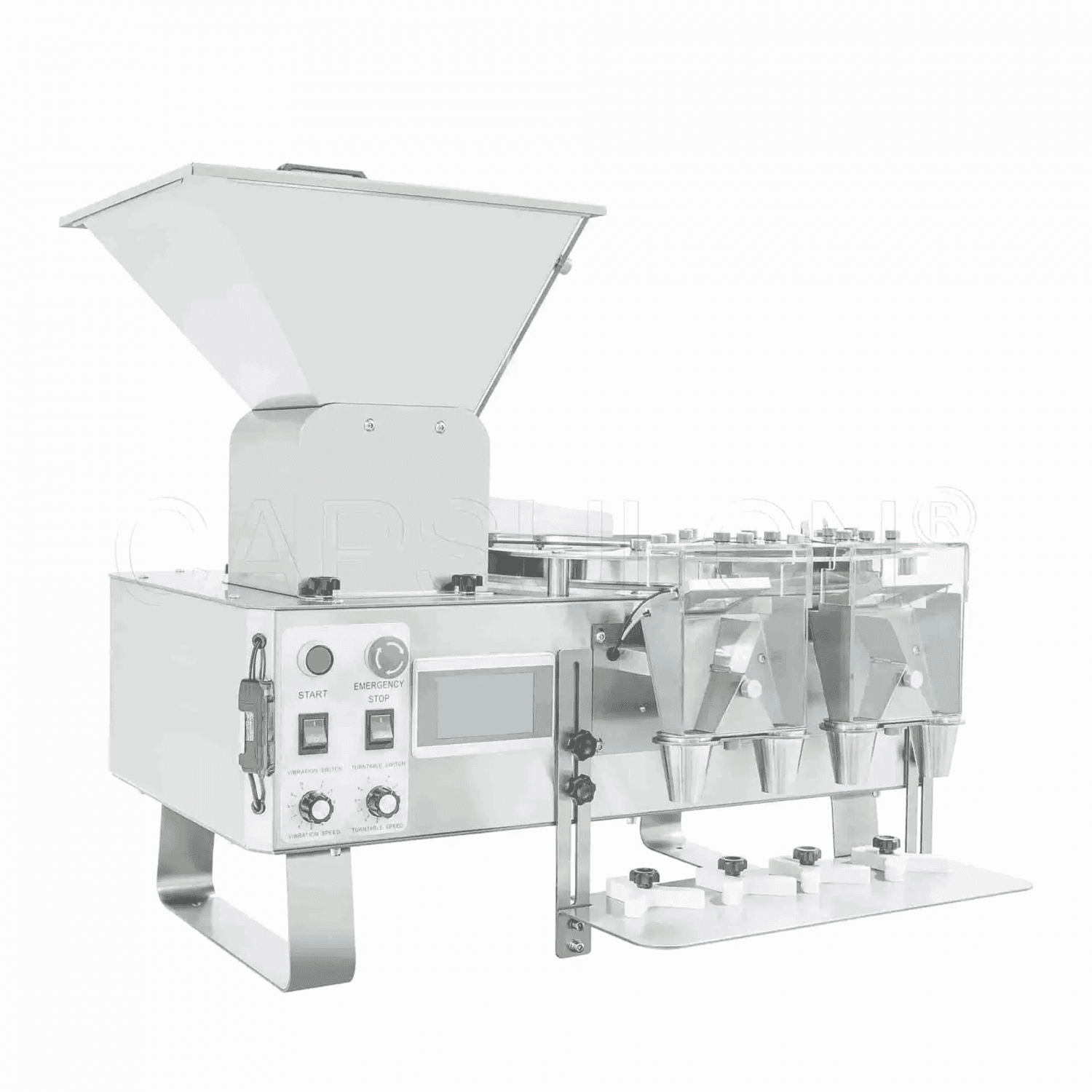

Semi-automatic tablet counters are more efficient than manual counters. These machines combine automation with human effort. Operators should load the tablets into the hopper and put containers under the filling nozzles. But they do not need to manually count them. The machine typically uses a vibrating tray or another mechanism to move tablets into a counting system. The system automatically dispenses the correct amount into containers. You can check the video to see how it works.

These machines increase the counting speed and reduce human error compared to manual counting. By combining human and machine power, it speeds up the process while maintaining some flexibility for smaller production volumes. But operators need some training to operate the machine well.

Fully Automatic Pill Counting Machines

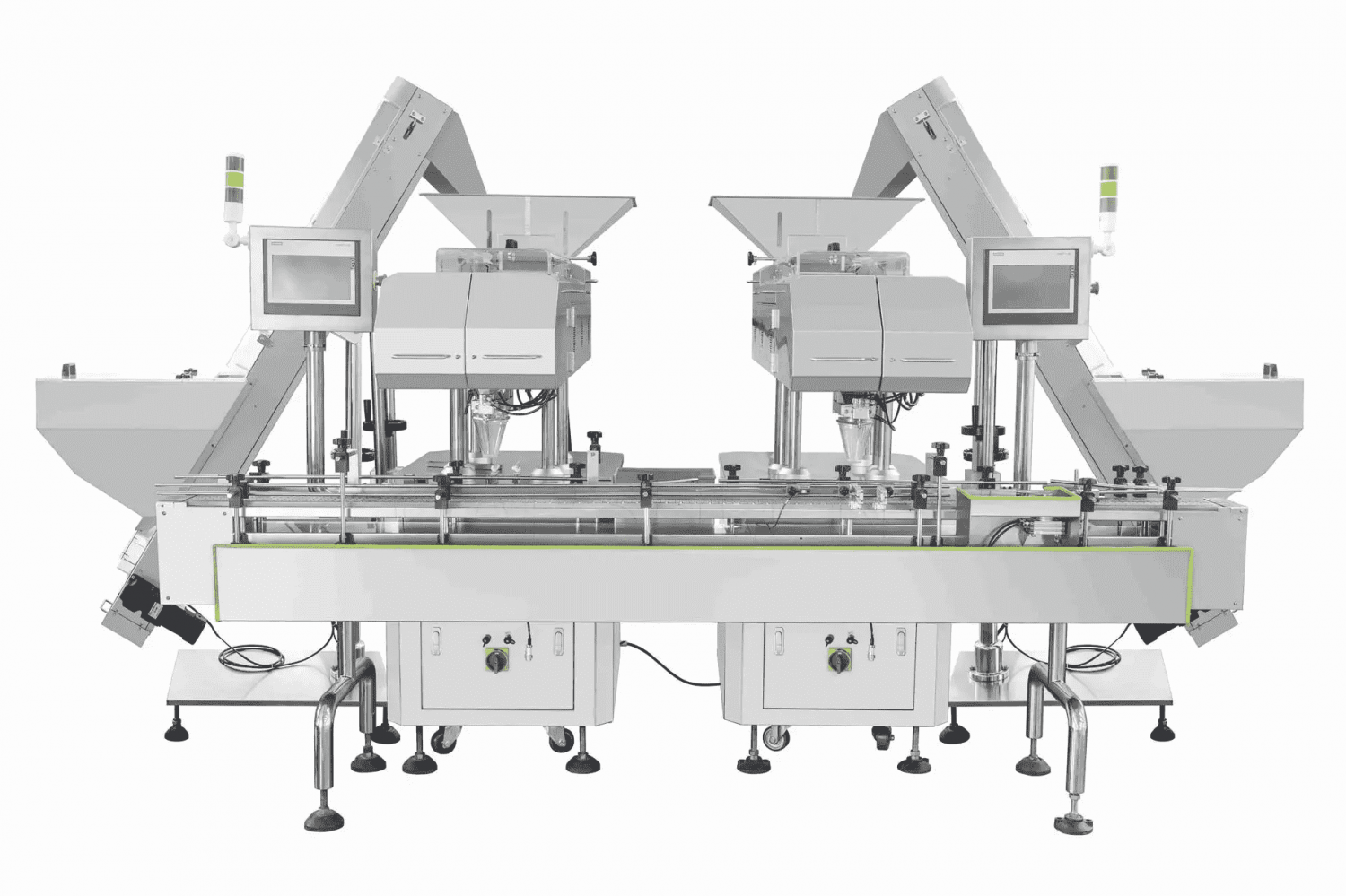

Fully automatic tablet counters are designed to handle large-scale production with minimal human effort. These machines use advanced technology to automate the entire counting process. It could operate from loading tablets to packaging them. The operator only needs to set up the machine and monitor it during operation. Tablets are automatically fed, counted and dispensed into containers when the correct quantity is reached. Automatic models feature high efficiency and consistency. It makes them ideal for high-volume production lines. The automation ensures that each batch is counted accurately and quickly, with minimal risk of error. Here is a video to show you how they work.

However, fully automatic tablet counters come with a high initial cost and require regular maintenance to ensure smooth operation. They also require skilled operators for setup and troubleshooting. So they may be less suitable for small businesses or low-budget operations.

Three types above are classified based on automation levels. Now I want to introduce you 2 other types according to counting mechanism.

Electronic Counting Machines

Electronic counting machines use advanced sensors, such as optical or infrared, to count tablets with high accuracy. These sensors are always put on the channels. When tablets move through them, the correct number can be counted before they are dispensed into containers. These machines feature great precision and adaptability. They provide accurate counting even for irregularly shaped tablets. In this case, manual machines cannot always handle them efficiently. But electronic counting machines cost more. In addition, they also require regular calibration to maintain their accuracy. It can increase operational costs.

Vibratory Counting Machines

This type of equipment uses vibration to move tablets across a series of trays or channels. These machines often work with sensors or mechanical gates to count tablets as they pass through. The vibration ensures a smooth and steady flow of tablets. This reduces the chance of overlap or double counts. This type of equipment is suitable for various shapes and sizes. But it may not be ideal for small or light tablets.

How to Choose a Tablet Coating Machine?

Some factors should be considered when you choose a tablet coater for your business. Here are some suggestions.

Tablet Properties

Main considerations include tablets’ sizes, shapes and fragility. They can greatly impact the counting process. Large or irregularly shaped tablets may be difficult to move smoothly through standard counting mechanisms. On the other hand, fragile or coated tablets require gentle handling to prevent chipping or breakage. Take sugar coated pills for example. They easily break down during processing. So many manufacturers choose machines equipped with non-contact optical sensors and adjustable channels. This ensures accurate counting without compromising tablet integrity.

Smooth Integration

It is important to make sure your new equipment can seamlessly integrate with your other machines, such as packaging and labeling machines. This won’t disrupt your production schedule and ensure high efficient working process.

Easy Cleaning

In every area, hygiene is a key factor, especially in pharma and food. So your machine should be cleaned thoroughly after every batch. An easy-to-clean machine is undoubtedly much helpful. It minimizes downtime and contamination risks.

The End

As a leading Chinese machine manufacturer, Huada Pharma has helped thousands of clients to get good tablet coating machines. We provide different types of coaters, and you can tell us your requirements to get the most suitable one. We also offer customization options. Whether you need to change size or material, we’ll meet your needs in detail. In addition, we can arrange shipping with good price and deliver the machine to your designated place.