Are you looking to invest in a tablet press? Let me guess - You're feeling overwhelmed by the multitude of options available. Since tablets are one of the most popular pharmaceutical solid dosage forms, there is a vast selection of tablet presses on the market. But fret not. You've come to the right place!

To help you make an informed choice, we've put together this ultimate tablet press buying guide. From exploring the various types of tablet presses to discovering their remarkable benefits, we'll equip you with everything you need to find the perfect equipment. Get ready to take your tablet manufacturing process to the next level with this comprehensive guide!

What Are the Different Types of Tablet Presses?

Looking across the entire market, tablet compression machines are available in two main types. They are:

- Single-punch tablet presses

- Rotary tablet presses

These machines have distinct features and advantages. Each is engineered to serve specific production needs and suit different manufacturing scenarios.

Single-Punch Tablet Presses

Single-punch tablet presses are the most basic type of tablet compression machine. They come in the simplest construction, primarily used for small-scale production of tablets. This type of tablet press will be an ideal choice if you're looking to produce tablets for R&D or pharmacy use.

- A single-punch tablet press consists of an upper punch, a lower punch, and a die in between.

- The machine is easy to operate. Depending on the machine's design, the tablet manufacturing process can be hand-operated or semi-automatic.

- Due to their operation methods, the production output of single-punch tablet presses is lower than rotary presses.

- Tablets produced by a single-punch press may have slight weight and hardness variations.

- Single-punch tablet presses are more affordable compared to rotary ones.

Rotary Tablet Presses

Rotary tablet presses are also known as multi-station tablet presses. Compared to single-punch presses, they have multiple tooling stations to form tablets. Rotary tablet presses can be designed to cater to large-scale tablet production. Today, they are the most commonly used type of tablet press in the pharmaceutical and nutraceutical sectors.

- Rotary tablet presses are highly automated. They are designed for the continuous production of tablets in batches.

- A rotary tablet press consists of multiple tooling stations arranged in a circular turret, typically ranging from 10 to 50 stations or more.

- The tablet manufacturing process is divided into various stages. Each step takes place sequentially at different stations.

- Rotary presses offer better tablet uniformity in weight, hardness, and size than single-punch presses.

- These machines feature quick changeover. This allows them to exchange tooling for different production needs.

- The configuration of a rotary tablet press makes it more expensive than a single-punch press.

Working Principles of Tablet Presses

Before buying a tablet press, it's critical to figure out how it works. Since you've known that there are two types of tablet presses, let's take a closer look at their respective working principles.

How Does a Single-Punch Tablet Press Work?

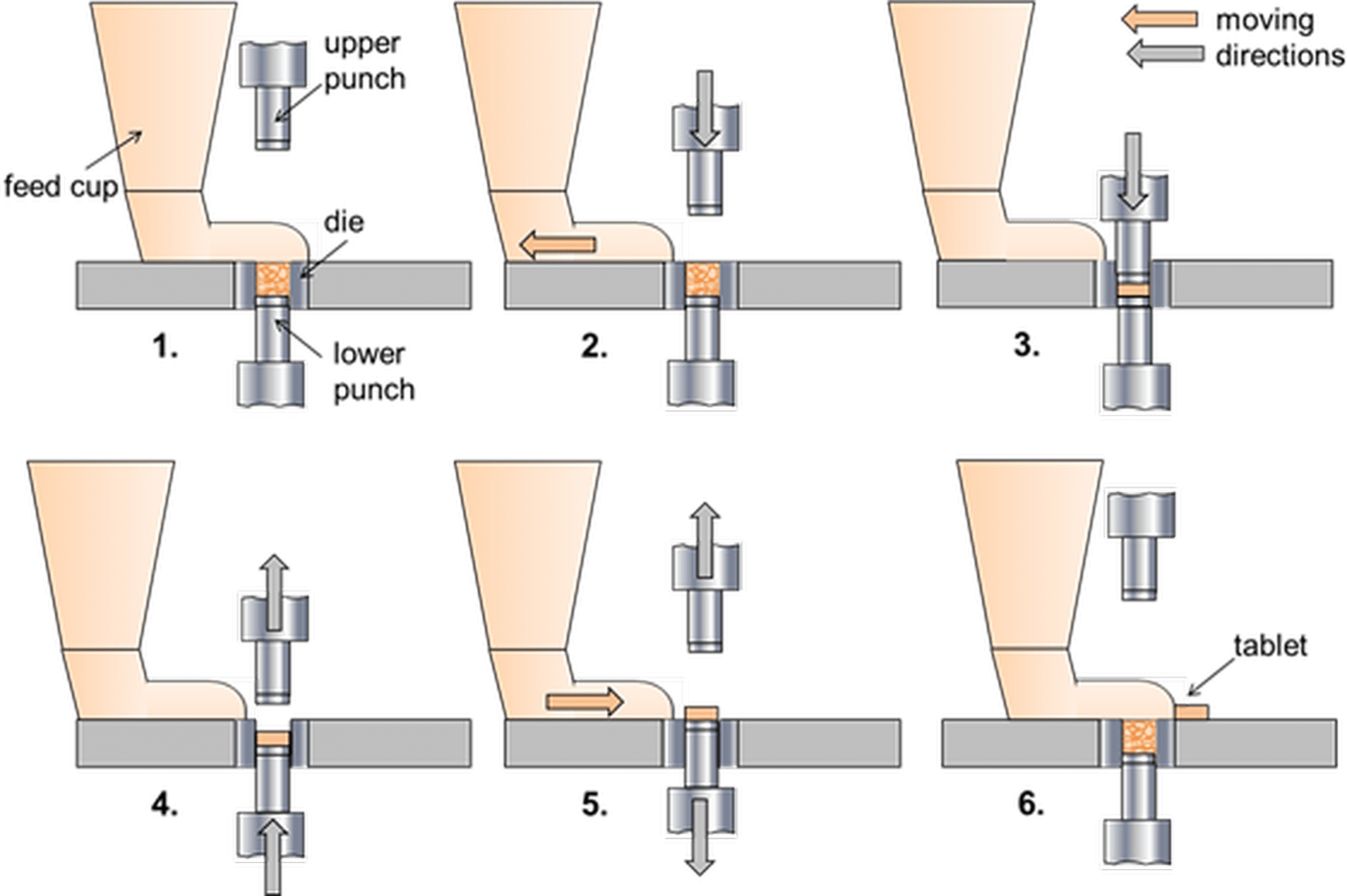

A single-punch tablet press uses only one station of tooling to produce tablets. So, it is also known as a single-station tablet press. The manufacturing process involves exerting compression force on the material to form one tablet at a time.

Typical steps in the manufacturing process using a single-punch tablet press:

1. Powders or granules are manually placed into the hopper.

2. The material flows from the hopper into the die cavity through a feeding mechanism.

3. The upper punch descends to compress the material inside the cavity.

4. The upper punch exerts high pressure on the material to form a compacted tablet.

5. After compression, the upper punch retracts. The lower punch ascends to push the formed tablet out of the die cavity.

6. A feed shoe swings over the die. This action propels the finished tablet downwards to a collection bin and refills the cavity for the next tablet compaction.

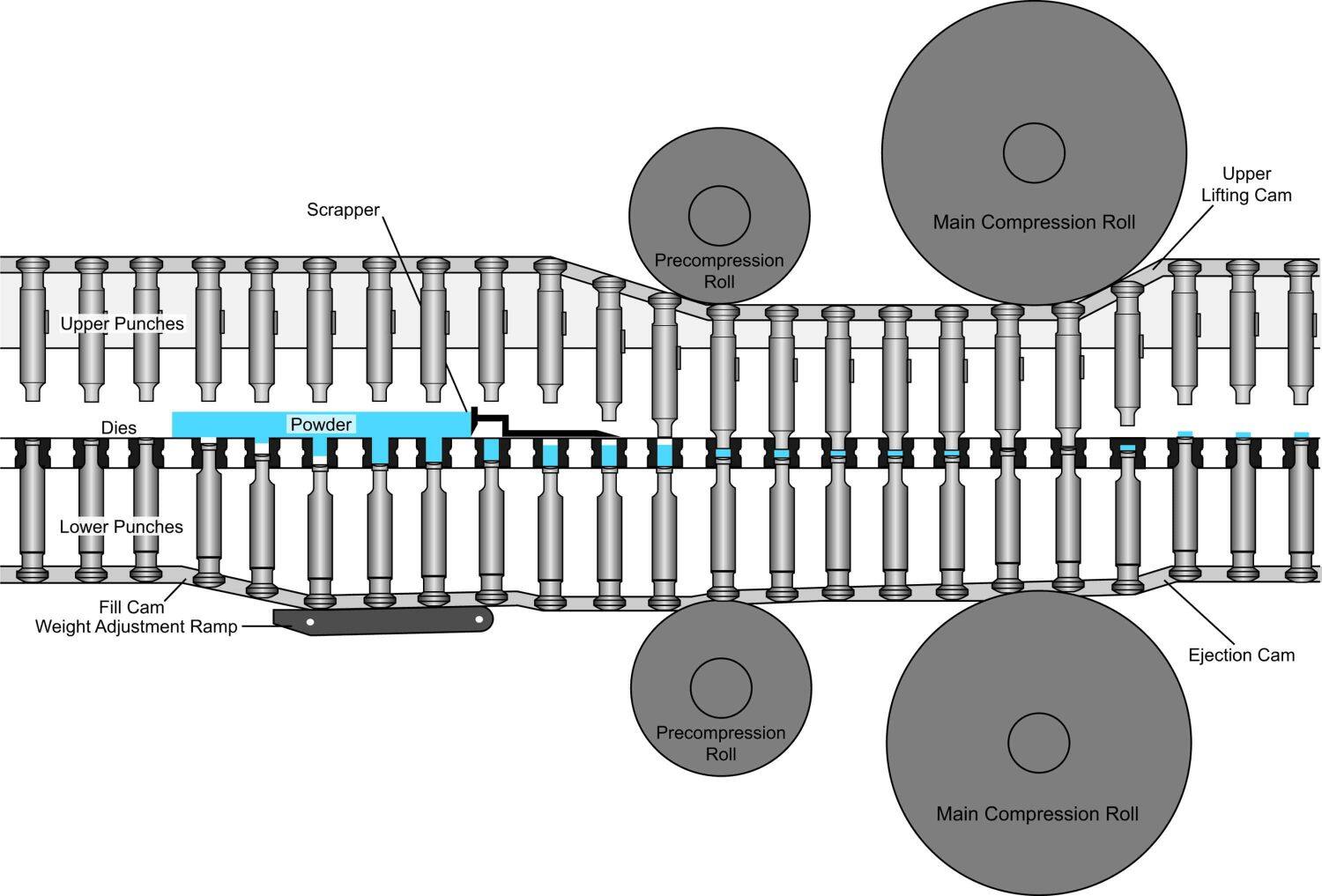

How Does a Rotary Tablet Press Work?

A rotary tablet press operates on almost the same principle. It uses multiple tooling stations and a turret to compress powders or granules into tablets. Thanks to the design, this tablet press can produce much more tablets in a shorter time than a single-punch tablet press.

Here are the steps to produce pills using a rotary tablet press.

1. Powder or granules are loaded into the hopper.

2. The material flows into a feed frame. The feed frame evenly distributes the material into die cavities.

3. A weight control unit measures the material flow into cavities.

4. When passing the precompression rollers, the upper punches apply moderate pressure to the material inside cavities to create slugs.

5. When entering the section of main compression rollers, the upper and lower punches exert higher pressure on the slugs to compact the material into the solid tablets.

6. After compression, the upper punches retract. The lower punches rise to push the formed tablets out of the die cavities.

7. The rotating turret carries the finished tablets to the take-off blade. The blade guides the tablets to the discharge chute.

Why Choose This Tablet Press?

Though all tablet presses employ a similar working principle, each type has its own advantages. This makes them cater to specific requirements and applications. By understanding their benefits, you can find the one that best suits your needs.

Advantages of a Single-Punch Tablet Press

- Compact size. These machines are relatively small and require less floor space. Most come in a tabletop style, making them suitable for home workshops, laboratories, pharmacies, or facilities with limited space.

- Cost-effectiveness. This is one of the selling points of single-punch tablet presses. With simple construction, these machines typically cost less to purchase and maintain than complex rotary presses. If you're new to the game, starting with a single-punch tablet press is a wise move.

- Ease of use. The simplicity of single-punch tablet presses makes them easy to operate. They require minimal training for operators to handle them effectively.

- Low energy consumption. These machines typically consume less energy as they come in a simple build with fewer mechanisms.

Advantages of a Rotary Tablet Press

- High production capacity. Rotary tablet presses are designed to run at a high speed. As the name suggests, they perform continuous rotary motion. Both features enable them to produce a larger number of tablets with minimal downtime. Some high-speed rotary tablet presses are capable of compressing over 200,000 tablets per hour.

- Consistent tablet quality. Rotary tablet presses are equipped with advanced technologies to control tablet weight, thickness, and hardness.

- Greater compression force. Rotary tablet presses can exert a significant compression force on the tablet formulation. This allows them to handle a wide variety of materials.

- Quick and easy changeover. Modern rotary tablet presses are designed for fast and straightforward tooling changeover. This means switching between different tablet formats or formulations can be done rapidly.

- Integration capability. Rotary tablet presses can be integrated into automated production lines. If you want to streamline your manufacturing process, connect them with other equipment, such as coating machines or blister packaging equipment.

5 Things to Consider When Buying a Tablet Press

The right tablet press should align with your quality standards, production goals, and budget. How to make an informed decision? Here are some important things to keep in mind when choosing a tablet press.

- Production Capacity

Determine the number of tablets you need to produce. Tablet presses come in different capacities, so choose one that can meet your production demands without being over or under-utilized.

- Tooling System

A set of tooling consists of an upper punch, a lower punch, and a die.

Each component is essential for compressing tablets. Check if the tablet press uses standard tooling or a custom tooling system. Custom tooling can be expensive but may be necessary for unique tablet shapes or sizes.

- Flexibility and Upgradability

If you want to benefit from your investment in the tablet press in the long term, be sure to choose a flexible machine. Such a tablet press can adapt to changing production needs, allowing for upgrades or additional features.

- Integration with Existing Equipment

Tablet presses come in different models. Some are standalone devices, whereas some feature integration capability.

If you intend to streamline your current production line, verify that the tablet press is compatible with your existing setup.

- Brand Reputation

For first-time buyers, going straight to a reputable manufacturer or supplier may be a shortcut to finding your ideal tablet press. This can save you time and increase the chance of getting reliable products and comprehensive customer service. Of course, you need to research and compare these vendors beforehand.

The Bottom Line

With the right knowledge, the tablet press purchasing process can be simple. Remember to consider the factors mentioned above. Also, take the time to do your homework when picking out a reliable vendor. We hope this buyer's guide has provided you with useful insights to make an informed decision. Happy tablet press shopping!