Tablet press is a key equipment for making tablets. It can compress powder into tablets of uniform size and shape. This machine plays a crucial role in many industries like pharmaceutical industry. Because they require highly consistent tablet quality. However, like all machines, a tablet press can experience issues that affect its performance.

So tablet press troubleshooting is necessary to keep the tablet press working smoothly. It helps find and fix problems before they get worse. This process ensures that the tablets produced are of high quality. Moreover, consistent tablet press troubleshooting also helps avoid delays in production. It also reduces the risk of machine breakdowns. Now let’s take a look at some main issues you may meet when using a tablet press machine.

Tablet Weight Difference

Some tablets may have different weight after production. It leads to incorrect amount of active ingredient and then it will greatly influence medicine effectiveness. This issue often occurs because the granules do not flow evenly into the die. It can be due to a feeder that is not working properly or is blocked. Sometimes, worn punches can also cause this problem, as they do not compress the granules correctly.

Another reason might be the turret spinning too fast or too slow. It causes uneven filling of the dies. To fix this filling tablet defect, it is important to adjust the feeder speed, clean or replace the feeder if necessary. Also, you need to check the punches for wear, replacing them if needed.

Tablet Lamination and Capping

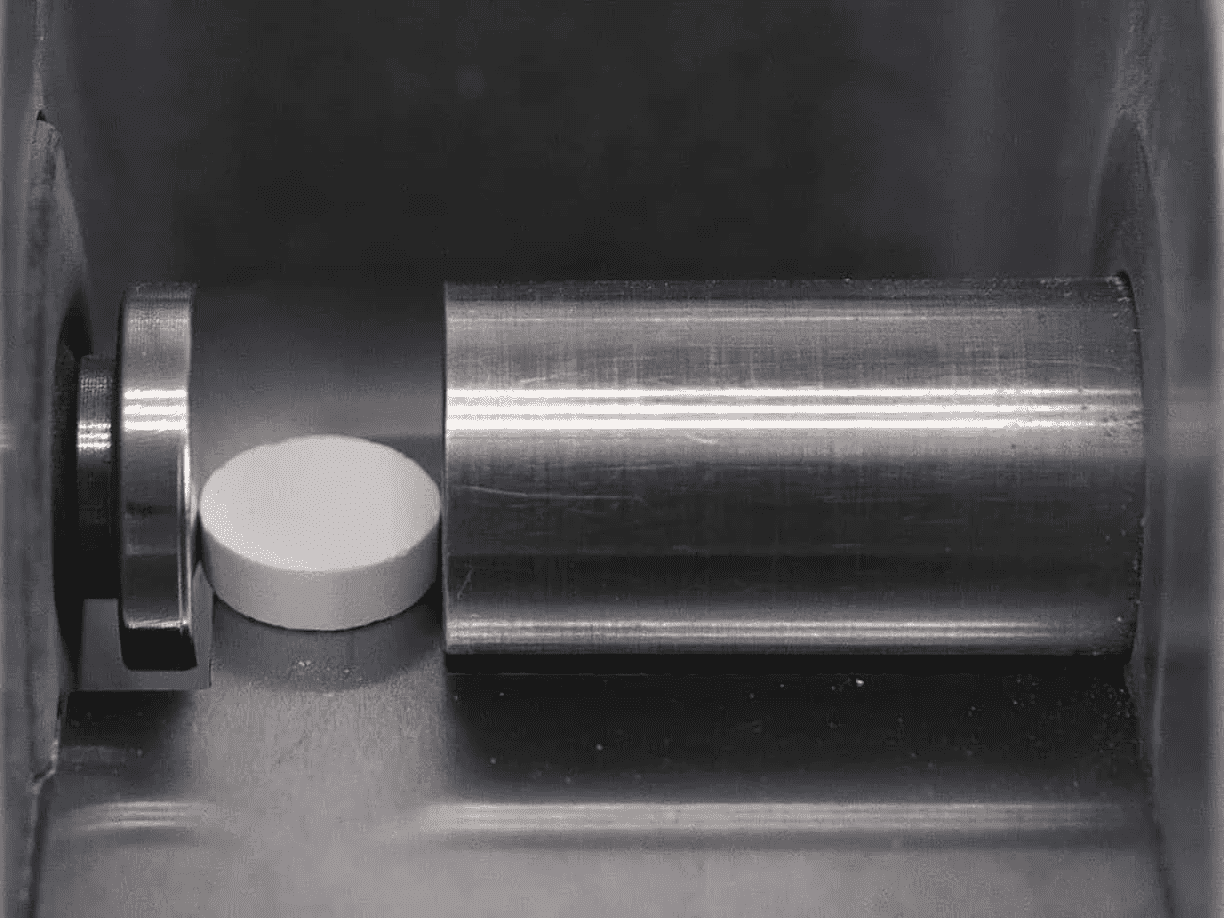

Tablet lamination and capping occur when the top or bottom layer of a tablet separates or when layers within the tablet split. These tablet capping and lamination problem in tablets occurs because the particles in the tablet do not bind together well. They are often due to too much air getting trapped inside during compression. Other reasons could include incorrect tablet formulation problems or worn punches.

So how to prevent capping in tablets? It is vital to adjust the tablet formulation by increasing the binder content. This helps the particles stick together better. Another way is to reduce the compression force. It can also prevent excessive air from being trapped. For more smooth production, you can regularly calibrate the tablet press. In addition. Don’t forget to replace worn punches to avoid further tablet issues.

Tablet Sticking and Picking

Picking and sticking are two common problems in the tablet compression process. Sticking happens when the tablet's surface sticks to the punch, making it hard to release the tablet. Picking refers when small pieces of the tablet get pulled away by the punch. The possible causes of these tablet problems are as follows:

- Powder that is too sticky.

To solve this problem, you’d better increase the amount of lubricant in the powder. It helps creates a barrier between the powder and the punch, making it less likely for the powder to stick. Or, you try to adjust the formulation to include less sticky ingredients or use anti-adherent agents. This further prevents the powder from sticking to the punches and die.

- Too much compression force.

You can decrease the pressure applied to the powder. It helps reduces the chances of the powder adhering to the punch.

- Rough or dirty punches.

These problems mainly cause picking. You can clean or polish the punches to solve the issue. Because smooth punches are less likely to pull small pieces of the tablet away during compression.

Tablet Chipping and Cracking

They refer to defects where the edges of the tablets break or crack. These chipping and cracking tablet defects are usually caused by materials. The reasons include high moisture content in the granules, or using too brittle granules. In addition, issues in machine also cause chipping and cracking.

If the tablet press is not properly calibrated, it might apply too much force. It would lead to cracking tablet defect. For chipping, it is always caused by worn or misaligned punches and dies. Because they apply uneven pressure when making tablets. It greatly influences the normal formation.

Various Hardness of Tablets

This tablet problem means tablets are too hard or too soft. It can affect their quality and how they dissolve. This problem often happens because the compression force used by the tablet press is either too high or too low. So the granules pressed are not the right size. This problem is also related to the tablet's formulation, like incorrect amounts of ingredients.

To solve these tablet issues, you need to adjust the compression settings on the machine for right amount of force. It’s also important to make sure the granules are of the correct size, not too big or too small. Furthermore, you should review the formulation to ensure all ingredients are balanced correctly.

Tablet Mottling

If you want to make colorful tablets, you may meet mottling in tablets. It refers to the uneven distribution of color on a tablet's surface, creating a spotted appearance. This tablet problem often results from an uneven mix of ingredients of machines, improper drying, or color migration during the manufacturing process. High humidity or inadequate blending can also lead to mottling.

To address this tablet issue, you should ensure proper mixing of all ingredients, and maintain a stable environment during production. Consistent monitoring and adjusting machine settings can also help prevent mottling in tablets and produce tablets with uniform color.

Other Common Tablet Issues

Besides the tablet issues mentioned above, the machine itself can also have some small problems that affect the operation. In most cases, you can solve them yourself. Take the pill tablet press ZP-9 for example.

| Fault | Cause | Solution |

| There is abnormal vibration during the machine’s operation. | The shock pad is ineffective. | Replace it. |

| The shafts of upper and lower pressing wheels are loose. | Adjust or replace them. | |

| The tablet pressing speed is improper. | Adjust it. | |

| Granules adhere to punch rods. | The surface of new granules is not smooth. | Redo the granulation. |

| There is too much fine powder. | Sieve the granules. | |

| Guide rail is worn. | Dry friction is caused due to lack of lubricating oil. | Add lubricating oil regularly |

| The surface of the worktable is worn. | The feeder is installed improperly and rubs the worktable. | Adjust the clearance to be less than or equal to 0.15mm. |

| There are hard impurities in the powder. | Remove impurities. |

How to Maintain Tablet Compressors?

Proper maintenance of a tablet press ensures smooth operation and extends the machine's life. Lubrication is essential in this process. Please note that some parts requires specific oils. For example, worm gear of ZP-9 needs N46 in summer and N32 in winter.

Regular checks are necessary for maintenance. Generally, monthly check is enough. For key parts, you’d better check them weekly, such as worm gears, bearings, etc. This way, if problems appear, they can be addressed quickly, avoiding major delays and losses.

After production, all residual powder should be removed, and the machine should be cleaned thoroughly. Please note that if the machine is not in use for an extended period, all punch dies should be removed, and cleaned. They also could be coated with antirust oil, and stored properly.