In the pharmaceutical industry, granulation is a key process to turn fine powders into larger and solid particles. When making tablets, sometimes powders need to be compressed into solid forms. Because if the materials are too small or uneven, they can cause problems like poor flow and uneven mixing. Granulation solves these issues. They can create uniform granules that are easier to compress and fill into capsules.

So granulators are important equipment in pharma manufacturing. They help pharmaceutical manufacturers produce granules with the consistent size and density. This ensures that every tablet contains the correct amount of active ingredients while mixing.

Three methods of granulation

There are 3 types of granulation used in the making process. Each has its unique features for different applications. You can choose the best one based on your production needs.

Wet granulation

Wet granulation needs liquid binders to make granules. The liquid acts like glue to stick the powder particles together. This liquid helps powders clump together to form small, and wet lumps. Then these wet lumps need to be dried for hardness and solidness. This method is usually used when powders can’t mix well because of some problems like poor flowability. Wet granulation is ideal for powders that are not sensitive to moisture or heat. It is not suitable for materials that can break down or change when they get wet.

Dry granulation

Compared to wet granulation, dry granulation doesn’t need any liquid. It uses pressure to make granules. The powder is first pressed into thick blocks called slugs. These slugs are then broken down into smaller pieces to make granules. Since no liquid is used, there is no need to dry the granules afterward. It makes this process quicker and simpler. But the granules might not be as strong as granules made by wet granulation.

This method is perfect for materials that are sensitive to moisture or heat. For example, some medicines can lose their effectiveness if they get wet. Dry granulation avoids this problem because it doesn’t use water.

Melt granulation

Melt granulation uses heat instead of water or liquid binders. In this process, a special binder is heated until it melts, like wax turning into liquid. This melted binder is mixed with the powder, and it coats the powder particles. Then it sticks them together to form granules. Once the binder cools down, it hardens and holds the granules together. This method works well for powders that can withstand heat. It is often used to make tablets that need to release medicine slowly over time, like controlled-release tablets.

Five common types of granulators

High shear granulators

This machine is used to turn fine powders into granules by mixing them quickly and forcefully. It works with a fast-spinning blade at the bottom of a mixing bowl. This blade cuts through the powder, mixing it thoroughly. At the same time, a liquid binder is added to the mix. The high speed of the blade helps the binder to form powders into granules.

High shear granulators work best with powders that need a lot of mixing to stick together. This machine also features great efficiency, making it useful for large batches of medicine. However, it’s not suitable for heat-sensitive materials. Because the process can create some heat and then affect the effective of medicine.

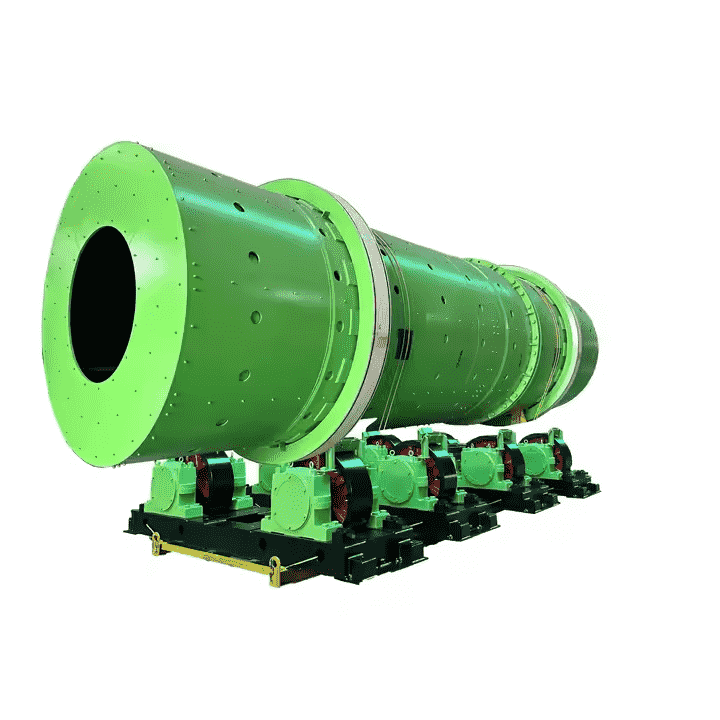

Rotary granulators

This machine operates with a rotating drum. Inside the drum, powders are mixed and tumbled around while a liquid binder is sprayed in. As the drum spins, the powder particles stick together and form solid granules. The rotation helps make the granules even in size and shape. This type of granulator is often used for products like fertilizers, medicines, and food supplements. It’s especially good for making granules that need to be smooth and strong.

This equipment excels in easy operation and low maintenance. It is also able to handle different types of materials. This machine works best for powders that can bind easily with a liquid.

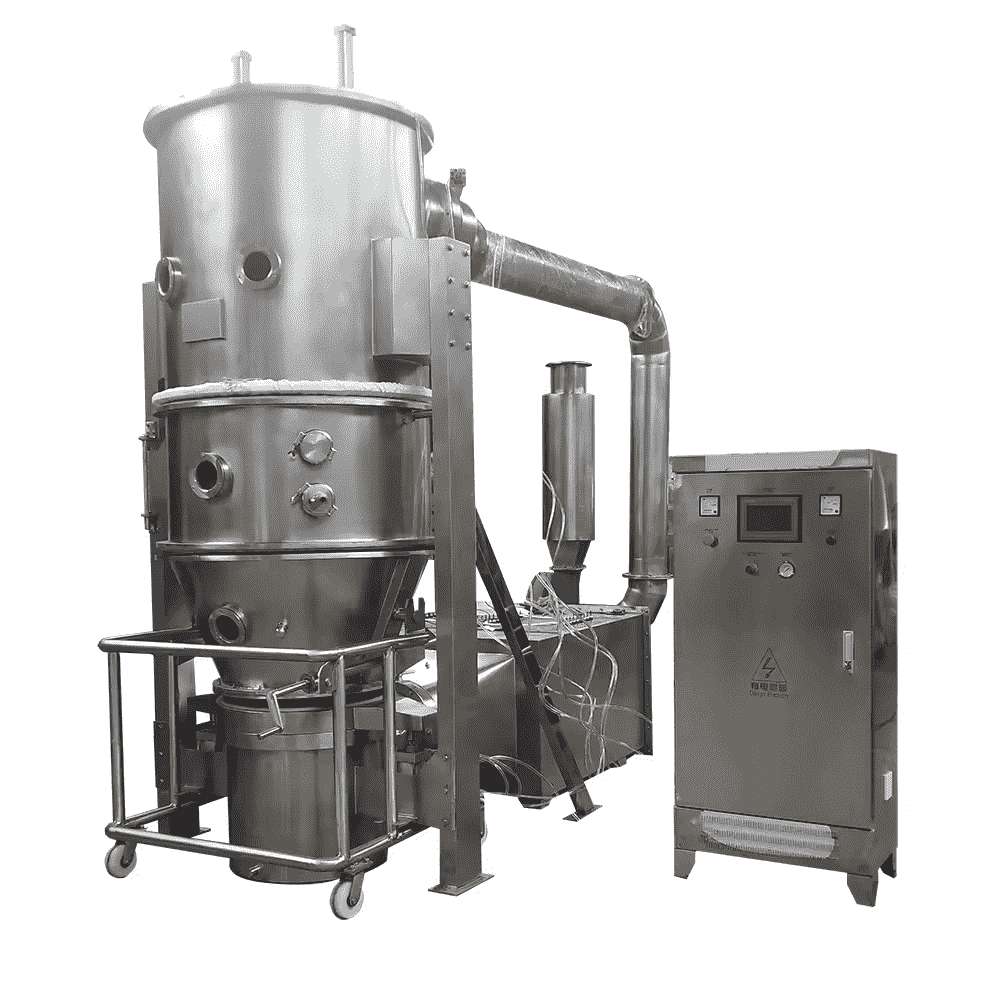

Fluid bed granulators

A fluid bed granulator make granules by suspending them in a stream of air. The machine works by blowing air through a bed of powder. It causes the particles to float like a boiling liquid. This allows the air to mix and heat the powder evenly. Then a binder is sprayed onto the powder particles to help them stick together and form granules. Fluid bed granulators are widely used in the pharmaceutical, food, and chemical industries. In the pharma sector, they are used to produce granules that are pressed into tablets or filled into capsules. In food production, they help create uniform particles for items like seasonings, spices, or additives.

These machines are popular because they allow precise control over the granulation process. They can also dry the material at the same time, which makes the process more efficient.

Three types above all belong to wet granulation methods. Now let me introduce you two granualtors that use dry granulation.

Roller compactors

A roller compactor make granules by pressing them between two heavy rollers. These rollers squeeze the powder into flat sheets or thick blocks. Then they are broken into smaller pieces to form granules. This machine is ideal for large-scale production. Compared to other granulators, roller compactors are better for dry materials. And they are a good choice when you want to avoid using liquids.

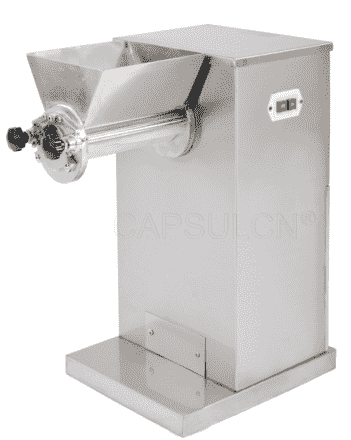

Vibrating granulators

A vibrating granulator turns fine powders into small granules by using vibration. The machine has a screen with small holes and a shaking part. This part supports to move up and down quickly. When the powder is placed inside, the machine starts vibrating. The shaking action pushes the powder through the holes, forming small, even granules.

This type of machine works well with powders that need gentle handling, such as vitamins or herbal products. Vibrating granulators are also easy to clean and maintain, making them popular in small or medium-scale production.

How to choose a suitable granulator?

Material types

This is an important factor you should consider. Different powders have different properties for processing. If your material are sensitive to moisture and heat, dry granulation is more ideal. Because they won’t lose effectiveness during the drying process. But if your ingredients can’t stick together easily or compact well, wet granulation is better.

Granule sizes

You should know at first what particle sizes you need. For uniform granules, a fluid bed granulator or high-shear wet granulator may be good choices. If you require larger and more irregular granules, a roller compactor might work better.

Energy cost

Granulators come in different sizes and designs. These factors can influence how much energy the machine uses. Some granulators, like fluid bed granulators, use more energy because they require heat, airflow, or motors running at higher speeds. So they often consume more power. If your production scale is large, energy-efficient models will help reduce operational costs in the long term. In contrast, simpler machines like dry granulators typically use less energy because they work by compressing the powder without heating or using additional liquids.

Upgrade your granulation with Huada Pharma

With 25 years of experience in pharmaceutical engineering, we provide various types of machines and packaging equipment, including granulators. If you have specific needs, just tell us your requirement in detail. Our team would assist you efficiently to meet your needs. If you need cGMP or CE certification, we can also offer it. Feel free to contact if you have any questions.