BliCN-350F Blister Machine

BliCN-350F Intelligent Plate AL/PL Blister Machine

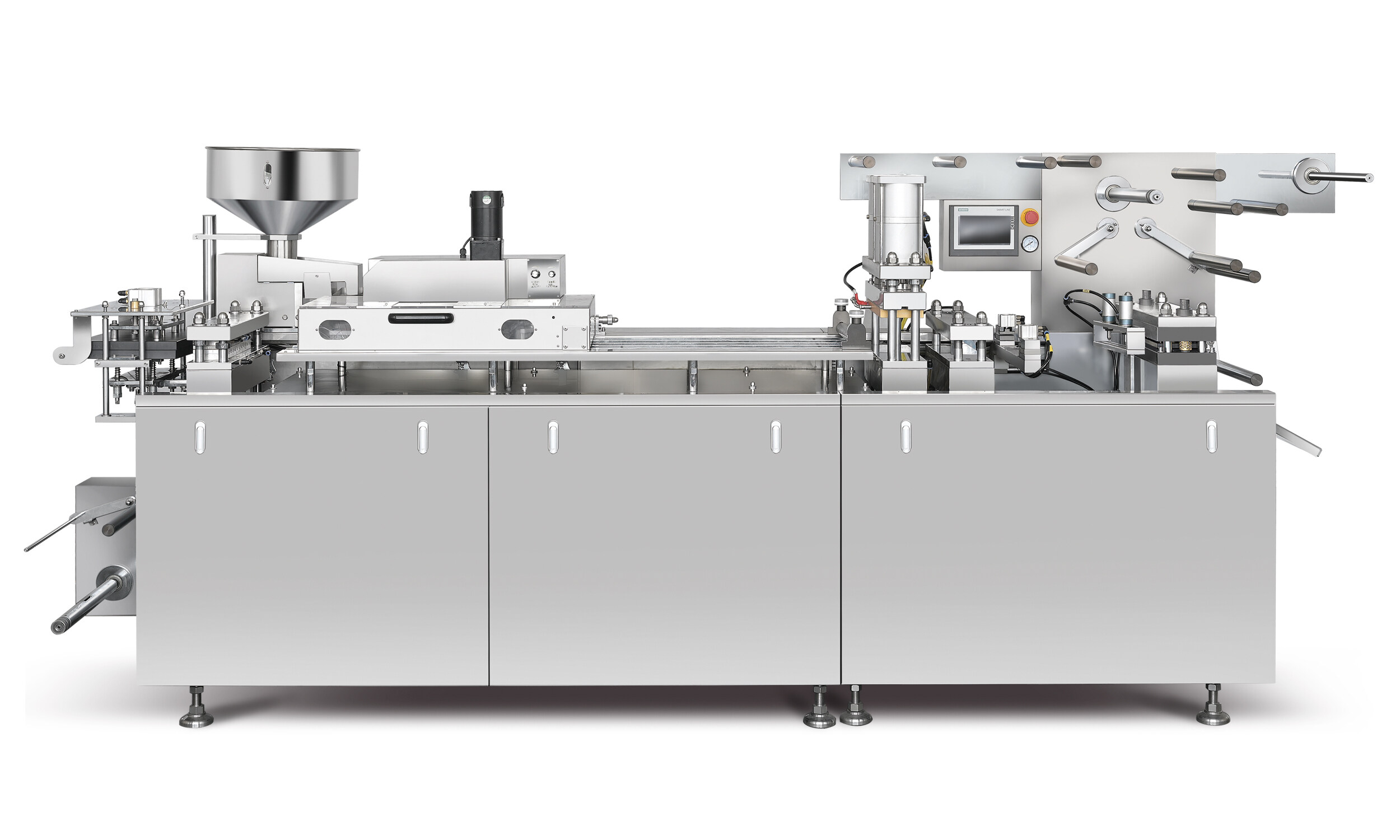

BliCN-350F is a blister machine in intermittent plate sealing principle, which is used for pharmaceutical packing, food packing, cosmetic packing, medical device packing, etc., and is applied to various types of products such as pharmaceuticals (tablets, capsules, ampoules), food, cosmetics, etc.

The blister machine is a special equipment for blister type aluminum/plastic, aluminum/aluminum (PTP) composite sealing packaging of pharmaceuticals (tablets, capsules, ampoules) food, medical devices and similar materials, which adopts positive pressure forming and flat pressure heat sealing, so it has the characteristics of the stiff and flat blister, and is popular among industry professionals.

Features:

- Max capacity 175 blisters/min

- Intermittent plate sealing

- Different feeding methods depend on customer needs

- PLC control system and Siemens smart 700 (7 inches) HMI screen

- Mechanical drawing, stable operation, adjustable stroke (optional servo drawing)

- Convenient mold change

- Scrap material collection

- Design in line with GMP requirements

Product Description:

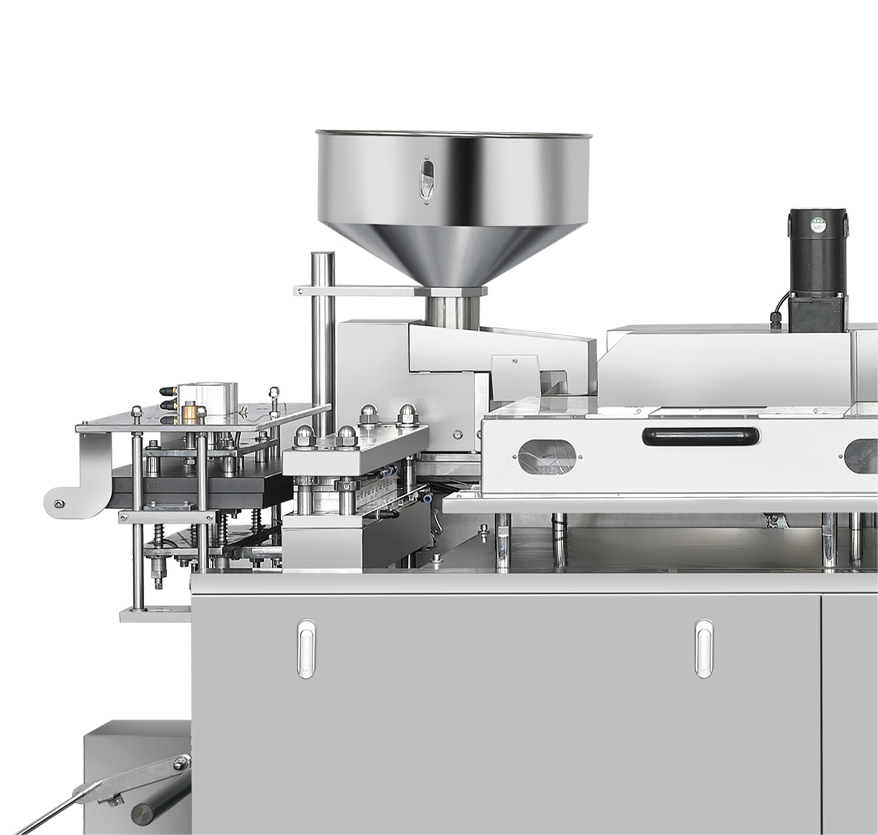

- The molds of the blister machine are positioned by keyway and fixed by pressing plate. Don’t need to adjust the parallelism and left/right movement when installing the forming mold and heat-sealing mold, so it is more convenient to change the mold

- This blister machine adopts variable frequency speed control: Setting the corresponding punching times according to the length of stroke and the difficulty of filling materials, etc.

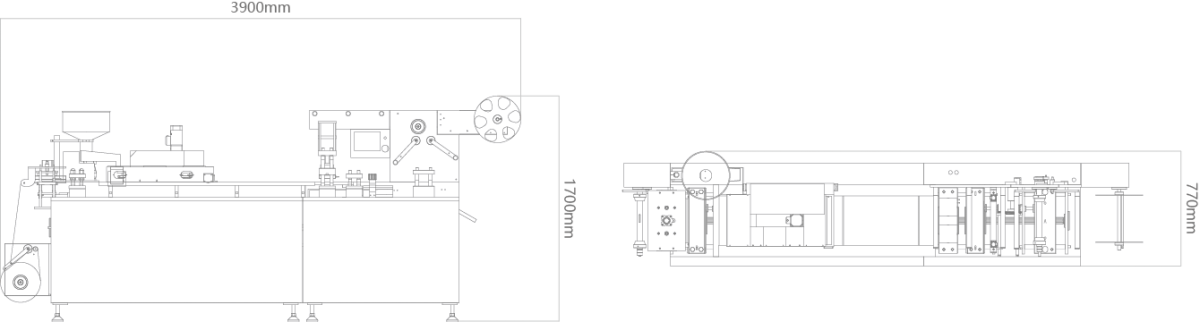

- The stroke of the blister machine is adjustable. Customers can design the plate size freely within the range of 30-120mm.

- This blister machine adopts compressing pair heating-plates, which shortens the heating length of the plastic film and reduces the heating power and temperature, thus enhancing the stability of the plastic film.

- Upper and lower mesh plates (concave and convex) cooperate for heat sealing (also can be line seal), due to equal stress, the curling phenomenon of blisters is avoided, meanwhile the sealing performance is improved.

- All parts in contact with medicine are made of stainless steel and non-toxic materials and are meeting “GMP” requirements.

- The production line with EMERGENCY STOP device, electronic counting, batch number, punching, automatic stopping and alarming if the film is used up or broken, etc. And has a smooth process and intuitive production process.

| Model | BliCN-350F |

| Max.Output | 60-105 blisters/min |

| Range of Stroke | 30-220mm |

| Max.Forming Area | 350*115mm |

| Max.Forming Depth | 18mm |

| Motor Power | 2.2KW |

| Power | 10KW |

| Power Three-Phase Five-Wire | 380V/50Hz |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China