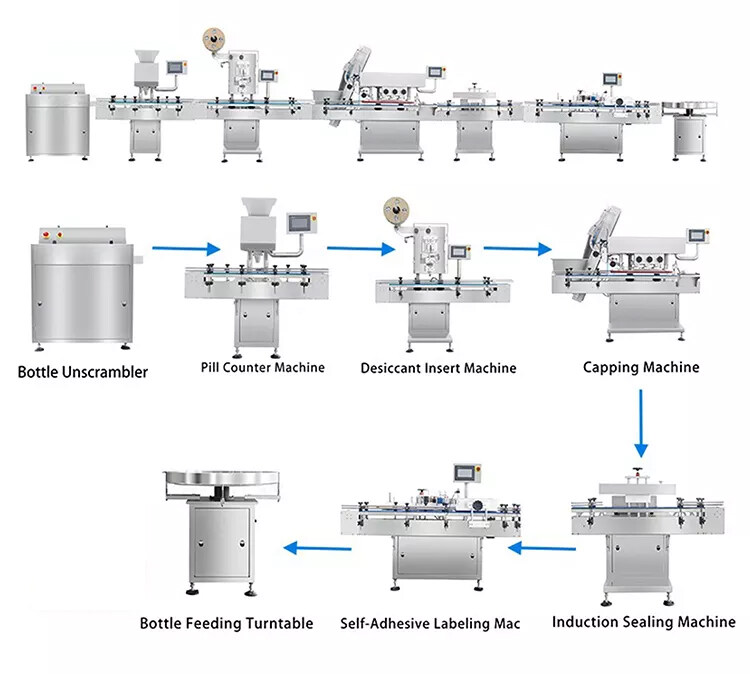

Capsule Bottling Packaging Production Line

Fully Automatic Capsule Bottling Packaging Production Line Pill Production Line

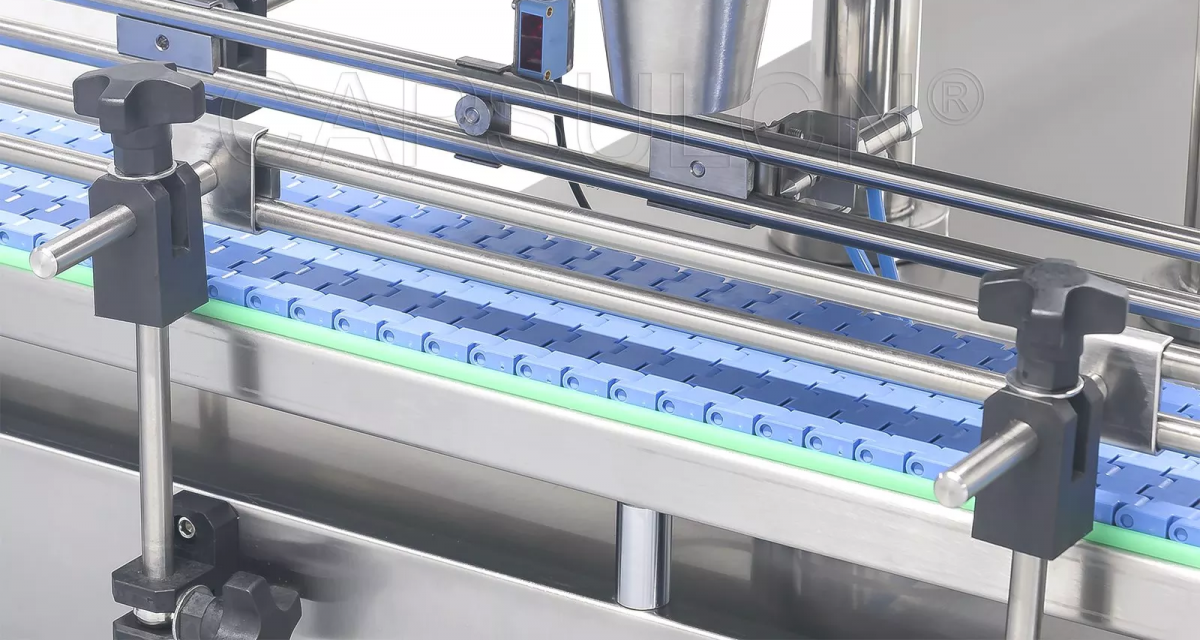

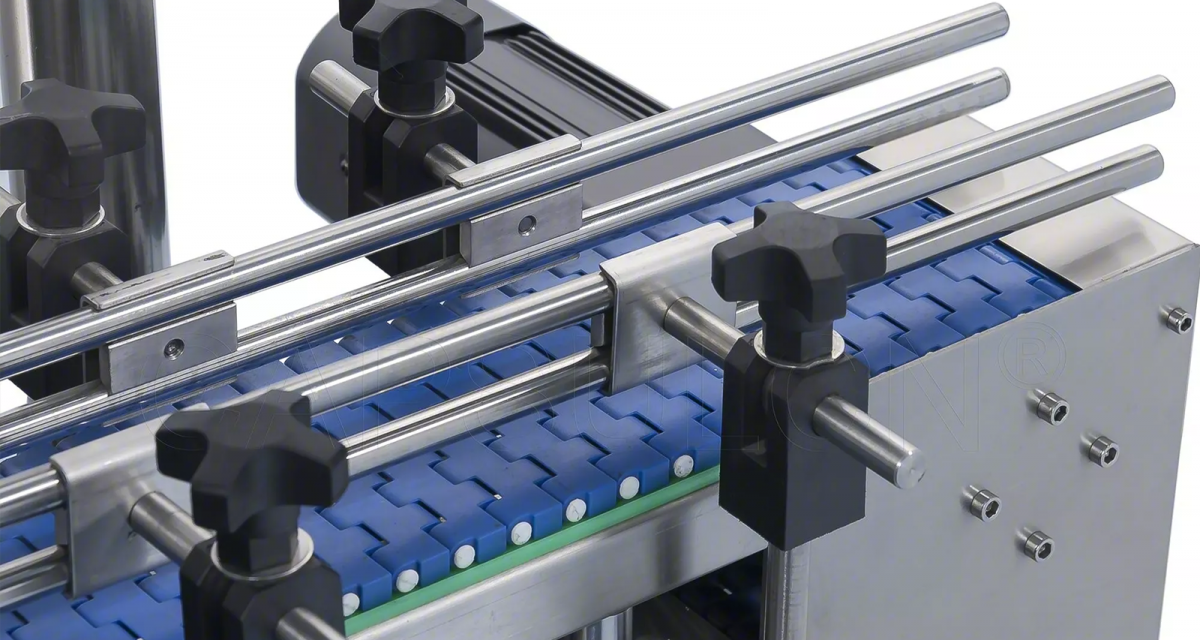

This complete automatic bottling line conforms to GMP standard. On the basis of practicability and efficiency, it can help you save cost and complete the bottling and packaging of products more accurately and beautifully. As you can see, it is of a high degree of automation, stable and reliable product performance, convenient operation and maintenance, exquisite and beautiful appearance. What’s more, it can ensure that every product under the production line is flawless. All you have to do is watching it produce!

| Bottle specification (ML) | 50~300 |

| Max. production capacity (Bottle/Min) | 60~100 |

| Power (kW) | 0.5 |

| Voltage (V) | 220 |

| Overall dimension (L*W*H) (mm) | 2200*1050*1900 |

| Weight (kg) | 250 |

| Rate of production | 10~30 bottles/min |

| Single bottling capacity | 2-9999 pcs/bottle |

| Common type | Pills, tablets, soft and hard capsules and other solid tablets |

| Pharmaceutical specifications | φ3~φ20mm solid granules, 0~5# hard capsules, soft capsules, other solid granules |

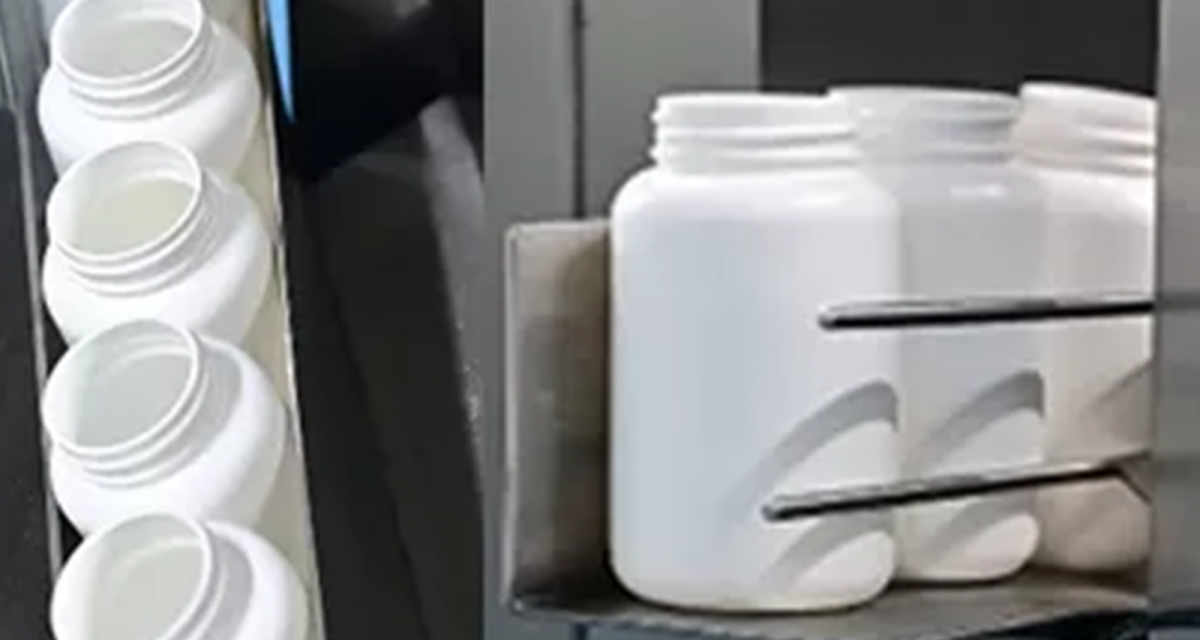

| Bottle diameter | φ20~φ100mm |

| Bottle height | 40~240mm |

| Filling speed of desiccant sachets | 50~120 bottles/min |

| Bottle’s outer diameter | Φ20~80 mm |

| Bottle’s height | 35~200 mm |

| Applicable range of desiccant sachets | 0.5~2 g |

| Total power | 500 W |

| Voltage | 220V 50Hz |

| Conveying direction | Left to right |

| Overall dimension (L*W*H) | 1150*800*1900 mm |

| Weight | 300 kg |

| Bottle’s outer diameter | Φ23~120 mm |

| Bottle’s height | 45~150 mm |

| Max. production capacity | 50~120 bottles/min |

| Bottle cap’s outer diameter | Φ20~120 mm |

| Total power | 1.8 KW |

| Voltage | 220 V |

| Overall dimension(L*W*H) | 2200*1050*1900mm |

| Weight | 650 KG |

|

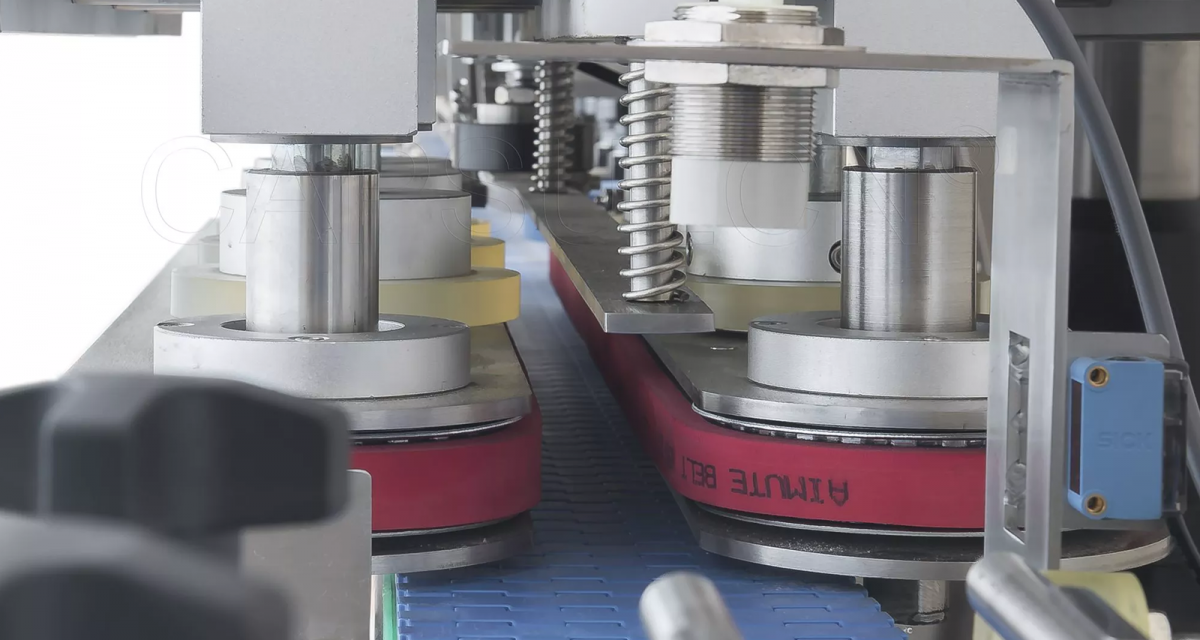

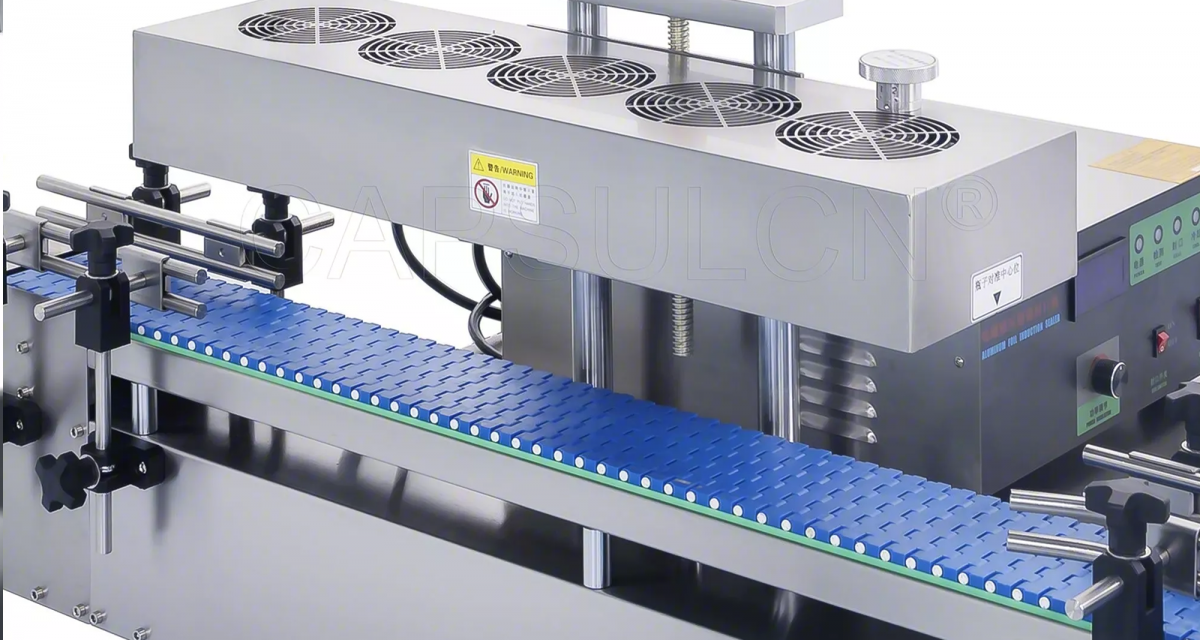

Sealing speed

|

120~200 bottles/min

|

|

Input power

|

~220V±10%, 50/60Hz

|

|

Input current

|

≤3.5A (when no bottles pass)

|

|

≤10A (when bottles pass)

|

|

|

Output power

|

Max. 2 kW (adjustable)

|

|

Output waveform

|

60~80KHz (Sine wave)

|

|

Protection class of machine shell

|

IP21

|

|

Sealing diameter of heating head

|

ø20mm~ø60mm

|

|

Labeling speed

|

20~120 bottles/min

|

|

Bottle’s outer diameter

|

Φ20~80 mm

|

|

Bottle’s height

|

35~200 mm

|

|

Applicable label length

|

23~250 mm

|

|

Applicable label height

|

15~125 mm

|

|

Total motor power

|

150 W

|

|

Voltage

|

220V, 50Hz

|

|

Conveying direction

|

Left to right

|

|

Overall dimension

|

2000mm*700mm*1650mm

|

|

Weight

|

280 kg

|

|

cartoning speed

|

30-120 cartons/min

|

|

carton quality requirements

|

300-350g/m²

|

|

dimension range of carton

|

(60-200)mm×(25-85)mm×(15-65)mm

|

|

user manual unfolded size range

|

L(80-300)×W(70-210)mm

|

|

user manual folded size range

|

L(70-210)×W(20-40)mm

|

|

air consumption

|

15-20m³/h

|

|

dimensions

|

3150 mm×1180 mm×1950mm

|

|

net weight of machine

|

about 1500kg

|

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China