Tablet And Capsule Counting Line Customized

Tablet And Capsule Counting Line Customized

Fully meet GMP requirements. Under the principle of practicality and efficiency, we will save cost for you and make your bottling and packing more accurate and beautiful. Our product quality is stable and reliable, easy to use, convenient maintenance, beautiful appearance. At the same time, it also ensures the perfection of each product line.

You can choose the whole production line according to your requirements, or only a few.Because of the coordination between each machinery and equipment, so that the production efficiency has been greatly improved, but also to product packaging quality and grade has been greatly improved.

You can customize the line as your request

Option 1: Turntable—Counter—Turntable—Induction sealer—Collecting Table

Option 2: Turntable—Counter—Induction sealer—Collecting Table

Designed to comply with FDA and cGMP regulation

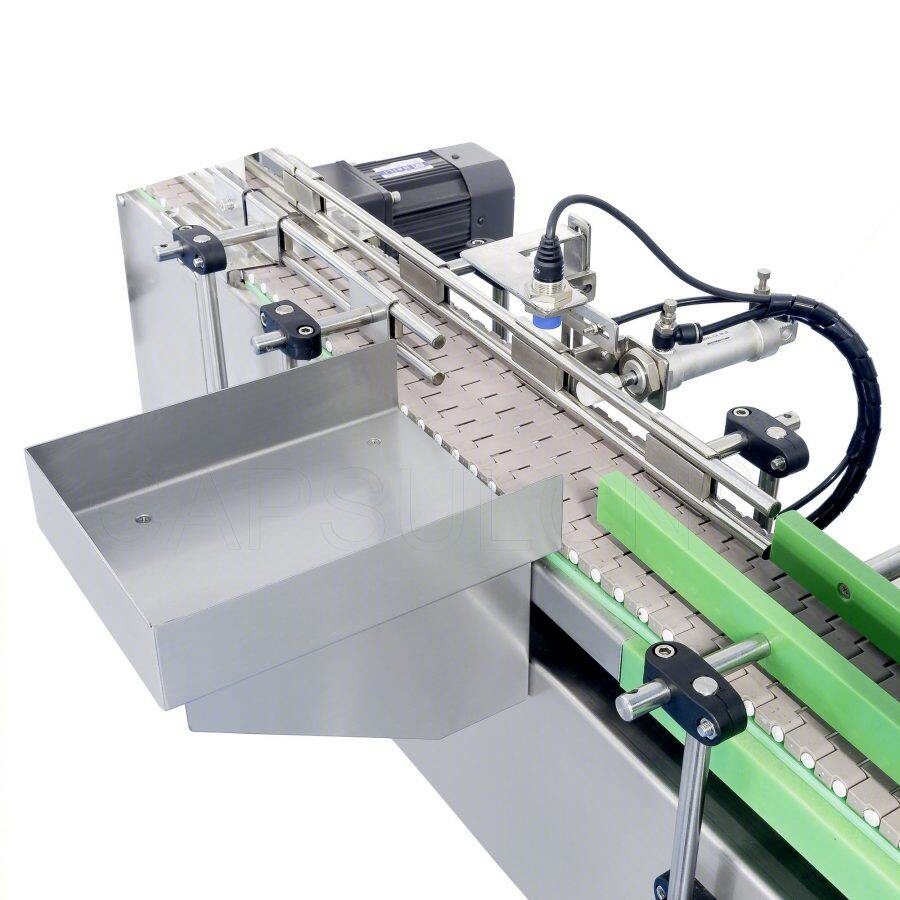

This machine is used to unscramble various plastic bottles of different shapes and specifications in pharmaceutical enterprises. It is a great supporting equipment for plastic bottle production lines.

The working process is to load medicines (capsules/tablets) into the hopper firstly and then start the vibrator. Product was conveyed through the vibrating channels and fall into the sensor chamber after line up. Six sensors (each head) in the sensor chamber execute counting simultaneously. The sixth cylinder gate act forward when every bottle counts up, Cylinder keep forward till the bottle was filled completely.

The working procedure of PBFK-260 Induction sealing machine is as below.

Firstly, the filled bottles go through the no-foil bottle rejection system by the conveyor. If no foil, the system will reject the relative bottle. Then the bottles enter the induction sealing head which makes the aluminum foil generate the heating to seal on the bottle mouth. This machine adopts no-contact induction sealing between the bottle and sealing head which make the bottle mouth seal properly.

Bottle Unscrambler

| Model | PBL-Z (Bottle-delivering unscrambler/ Bottle-collecting unscrambler) |

| Scope of application | Round bottles, square bottles, flat square bottles and special-shaped bottles of various materials |

| Production capacity | 30~200 bottles per minute |

| Diameter of bottles | 20~80mm |

| Power supply | AC220V/50Hz |

| Power | 0.1kW |

| Overall dimension (L*W*H) | 900*900*1000mm |

| Machine weight | 95kg |

Electronic Counting Machine

| Model | PBDS-8 |

| capacity | Max.50 bottles/min |

| Size of Bottle | 15-500ml |

| Voltage | AC220V, Single Phase, 50/60 Hz |

| Power | 600W |

| Air Consumption | 0.8 m³/hour |

| Air Pressure | 0.5 MPa |

| Overall Dimension(L*W*H) | 1600 *1600 * 1600 mm |

| Weight | 450kg (with conveyor) |

Sealing Machine

| Model | PBFK-260 |

| Bottle body dia. | Φ20~Φ100 mm |

| Bottle mouth dia. | Φ20mm~Φ50 mm |

| Bottle height | 30mm~200 mm |

| Capacity (Max.) | 150 bottles/min |

| Max. power | 4 KW |

| Power supply | AC 220V ±10%, 50/60 Hz |

| Air supply | 0.1 m³/h |

| Air pressure | 0.4 Mpa |

| Cooling water | Purified water |

| Environment Temperature | -10°C~40°C |

| Relative humidity | ≤ 90% |

| Dimension (L*W*H) | 1600*950*1250 mm |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China