GD150 Fully Automatic Gummy Making Machine

Fully Automatic Gummy Making Machine Gummy Bear Jelly Gummy Candy Depositing Line

Our Fully Automatic Gummy Making Machine is a reliable and efficient piece of equipment that has been localized for easy operation. Based on a similar machine from Australia, we have made necessary adjustments to ensure steady working and user-friendly features. The entire processing line includes cooking, depositing (with servo central-filled depositing), finished product transferring, powder disposing, and recycling system. Our customers have the option to choose the candy size, and we offer professional layout design to maximize production capacity while maintaining steady running and stable starch moulds. Our machine is designed to meet the demands of high-volume production while maintaining consistent quality. With our Fully Automatic Gummy Making Machine, you can expect reliable performance and quality results.

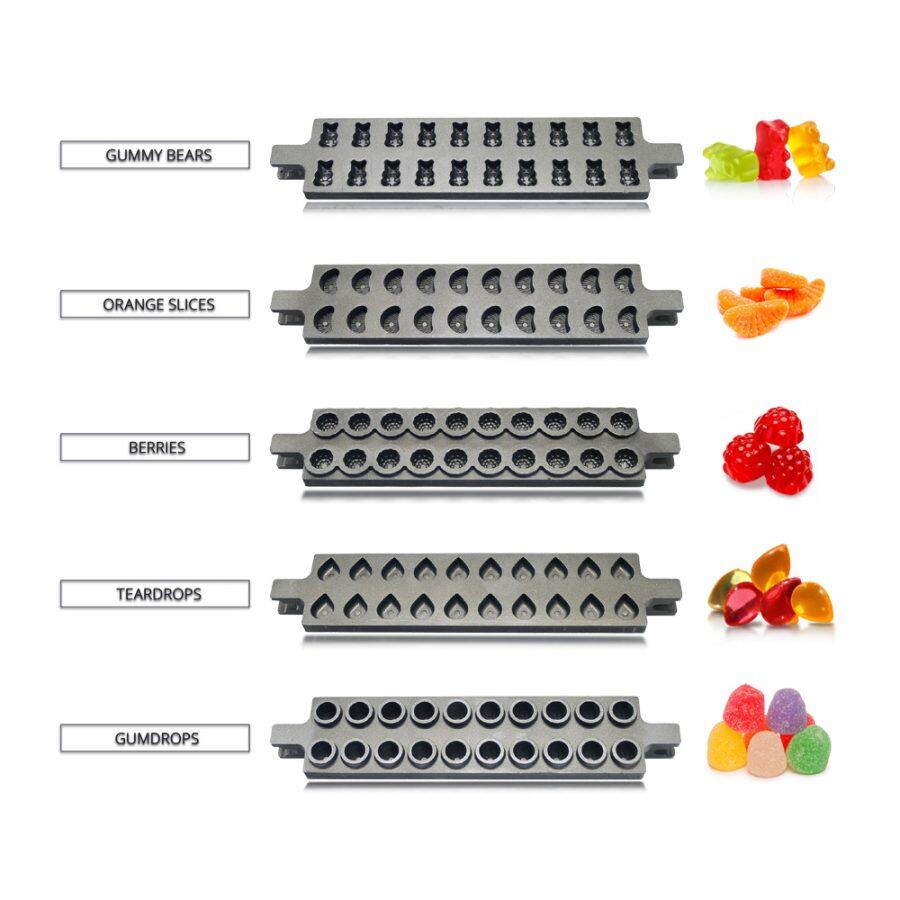

The equipment for making gelatin jelly candy comprises a cooking section, a depositing section, and a cooling section. The GDQ150 line uses one-row molds and can produce 100-150kg of candy per hour, depending on the weight of the pieces. The candy’s shape can be customized to suit the customer’s needs, and various designs are available. The candy can be made in single or double colors, with left-right or up-down patterns. Examples of the final product are provided in the photos below.

Features

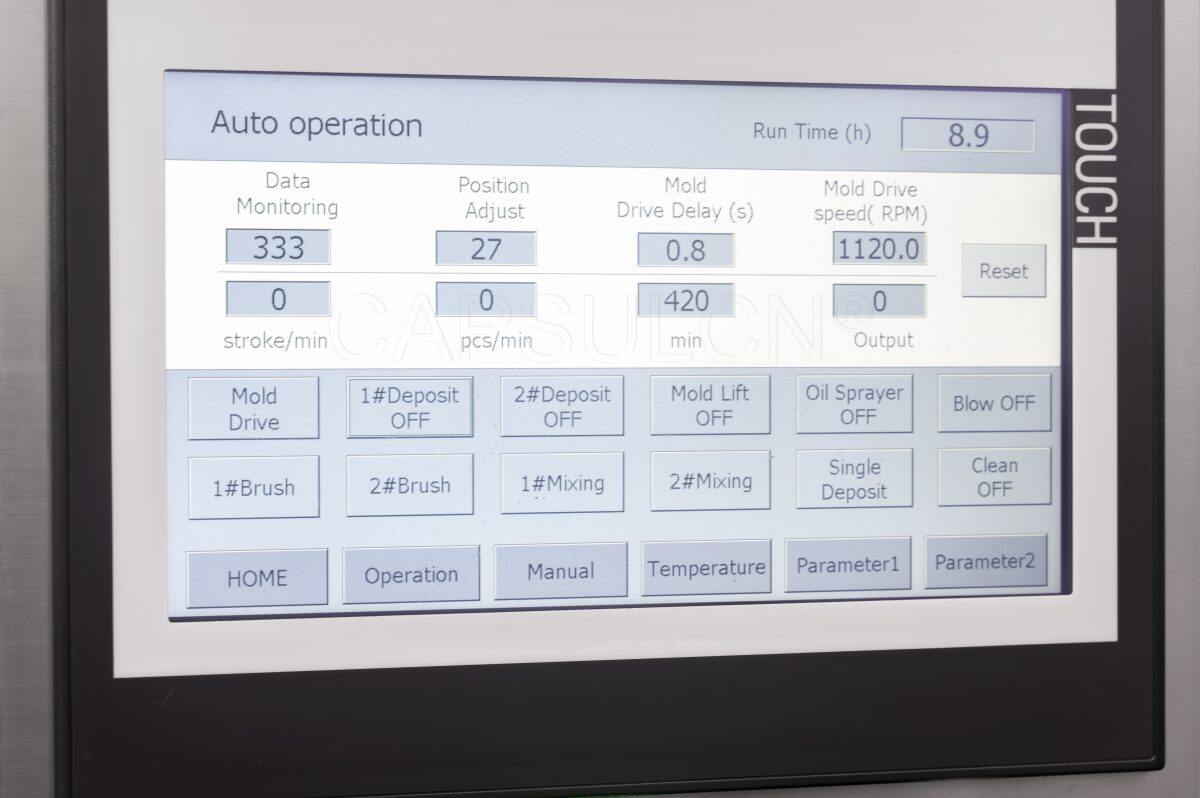

- The system is controlled by a PLC and has an LED touch panel for easy operation.

- It can produce 40, 80, 150, 200, 300kgs/h or more, based on 3.5g mono candy.

- The parts that come into contact with food are made of hygienic Stainless Steel SUS304.

- In-line injection, dosing and pre-mixing techniques are used for the proportional addition of liquid.

- Dosing pumps are also used for the automatic injection of colors, flavors and acids.

- The system uses an automatic steam control system instead of a manual steam valve to ensure a stable steam pressure for cooking.

- Moulds can be made according to the customer’s candy samples.

- There are also optional features available, such as an extra jam paste injection system for making fruit jam-center filled candies and mass flowing controlled by Frequency inverters.

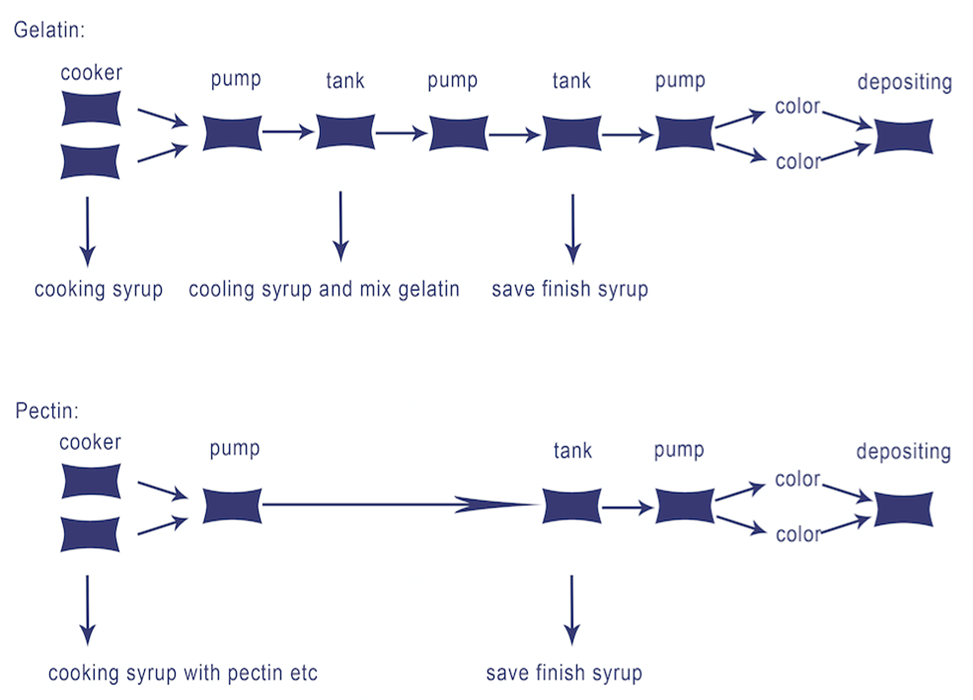

Working Process:

Details:

- Cooking

- Control Screen

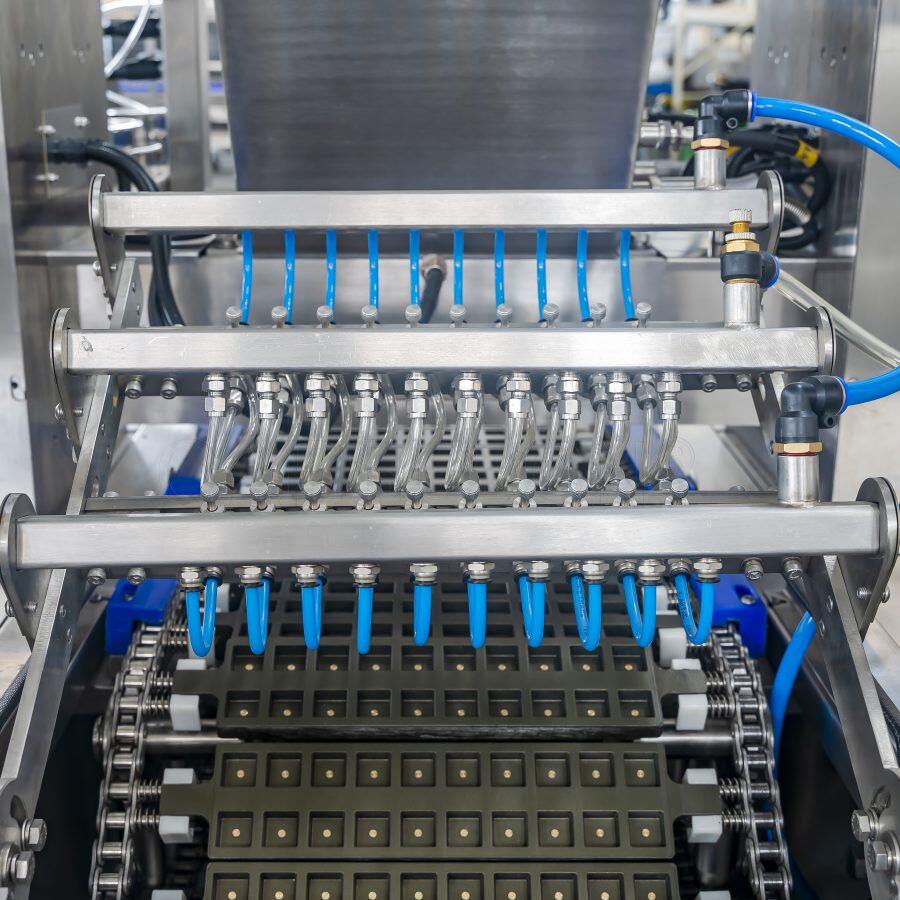

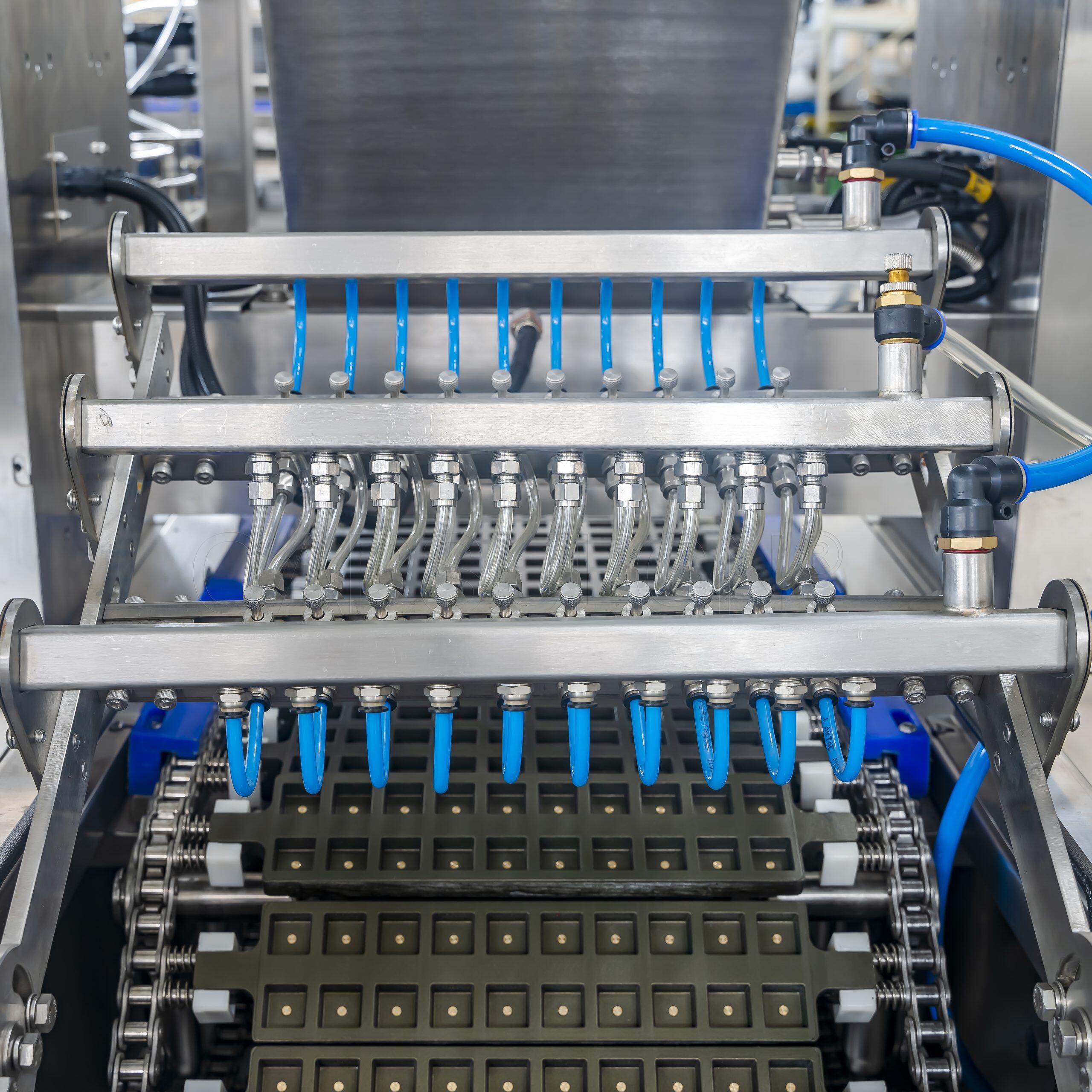

- Gummy Depositor

- Deposit

- Auto Mold Lubrication System

- Cooling

- Quick Release Molds

- Gummy Metal Mold

*Ultimate output per hour depends on several factors, such as; tank size, cleaning time and depositor speed.

| Model | GD150 | GD300 | GD450 | GD600 |

| Capacity | 150kg/h | 300kg/h | 450kg/h | 600kg/h |

| Candy weight | According to the size of candy | |||

| Depositing Speed | 25~55 n/min | |||

| Compressed air Requirement | 0.5M3/min,0.4-0.6MPa | |||

| Working condition | temperature:22-25℃ humidity 55% | |||

| Electric power needed | 16kW/380V | 26kW/380V | 32kW/380V | 36kW/380V |

| Total Length | 15m | 17m | 17m | 22m |

| Weight of machine | 3500kg | 4000kg | 4500kg | 6000kg |

| Name | Size | Download |

|---|---|---|

| FullyAutomaticGummyMakingMachine.pdf | 4 MB | Download |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China