Vertical Packing Machine

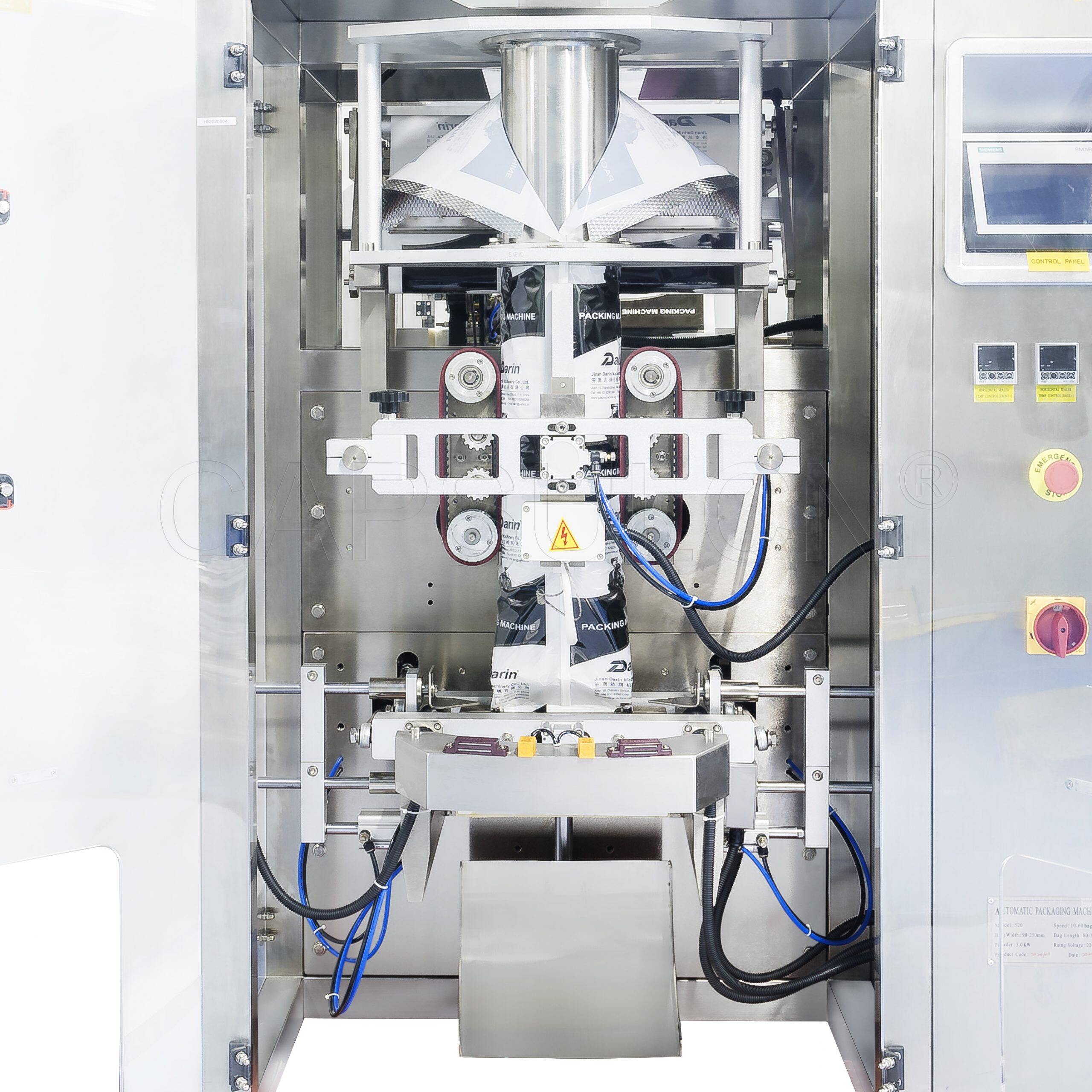

Vertical Packing Machine BVL-520

Vertical packaging machine, a variety of models economical vertical packaging machine frame is adopted 304 stainless steel material, equipped with the door security protection function, apply to the bag type has a pillow bags, Angle belt, printing bag, triangle bag bag type, suitable for all kinds of packaging materials, such as all kinds of leisure food, frozen food, coffee beans, oats, sugar, salt, rice, small hardware accessories, etc., affordable, cost-effective.

Introduction

Vertical bagging systems essentially refer to a specific kind of vertical packaging machine also known as a vertical form fill seal machine. This particular piece of bagging machinery and equipment is a type of automatic packaging unit that is commonly used in the food packaging industry.

Features

- The structure is compact, electrical components, pneumatic components used in the factory of products, to ensure long-term stable working machine

- The PLC program control, full Chinese / English touch screen operating system, clearly show the working state and operating instructions

- Adopts high precision servo film transporting system, transport membrane smooth, combined with photoelectric automatic tracking location system, high positioning precision.

- The intelligent digital temperature control system, temperature control and stability, sealing device with tooth, ensure firm sealing.

How it work?

- Film Transport & Unwind: the film is usually pulled off the roll by film transport belts

- Film Tension:During unwinding, the film is unwound from the roll and passes over a dancer arm which is a weighted pivot arm located at the rear of the VFFS packaging machine. The arm incorporates a series of rollers. As the film transports, the arm moves up and down to keep the film under tension. This ensures that the film will not wander from side to side as it is moving.

- Printing:Printers may be thermal or ink-jet type. The printer places desired dates/codes on the film, or may be used to place registration marks, graphics, or logos on the film.

- Film Tracking and Positioning:Once the film has passed under the printer, it travels past the registration photo-eye. The registration photo eye detects the registration mark on printed film and in turn, controls the pull-down belts in contact with the film at the forming tube.

- Bag Forming:From here, the film enters a forming tube assembly.

- Bag Filling and Sealing:formed bag can receive its vertical seal. The vertical seal bar, which is hot, moves forward and makes contact with the vertical overlap on the film, bonding the layers of film together.

Information we need before order

- What product will you pack?

- How many gram and volume in each bag?

- What bag shape you want to get?

- What is bag width and bag length?

- What bag material do you want to use?

| Model | BVL-520 |

| Packing film | OPP/CPP、CPP/PE ,etc composite materials can be hot sealing, require to use in roll. external diameter≤400 mm,inner shaft diameter 75mm;The surface of packing film must smoothly, Not have wavy on the edges, within 10mm of edge can not print words and figure, the mark and packaging film base color contrast to sharp. |

| Making bag size | (W) 90-250mm; (L) 80-360mm,the length can up to 450mm after pushing the belt second time. |

| Packing speed | 5-70bags/min |

| Thickness of Packing film | 0.05-0.10mm |

| Powder | 3.2 KW |

| Air consumption | 0.7Mpa 300L/min |

| Dimension | W118*L150*H153 (cm) |

| Weight | 650kg |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China