Dry Powder Mixer Blending Machine

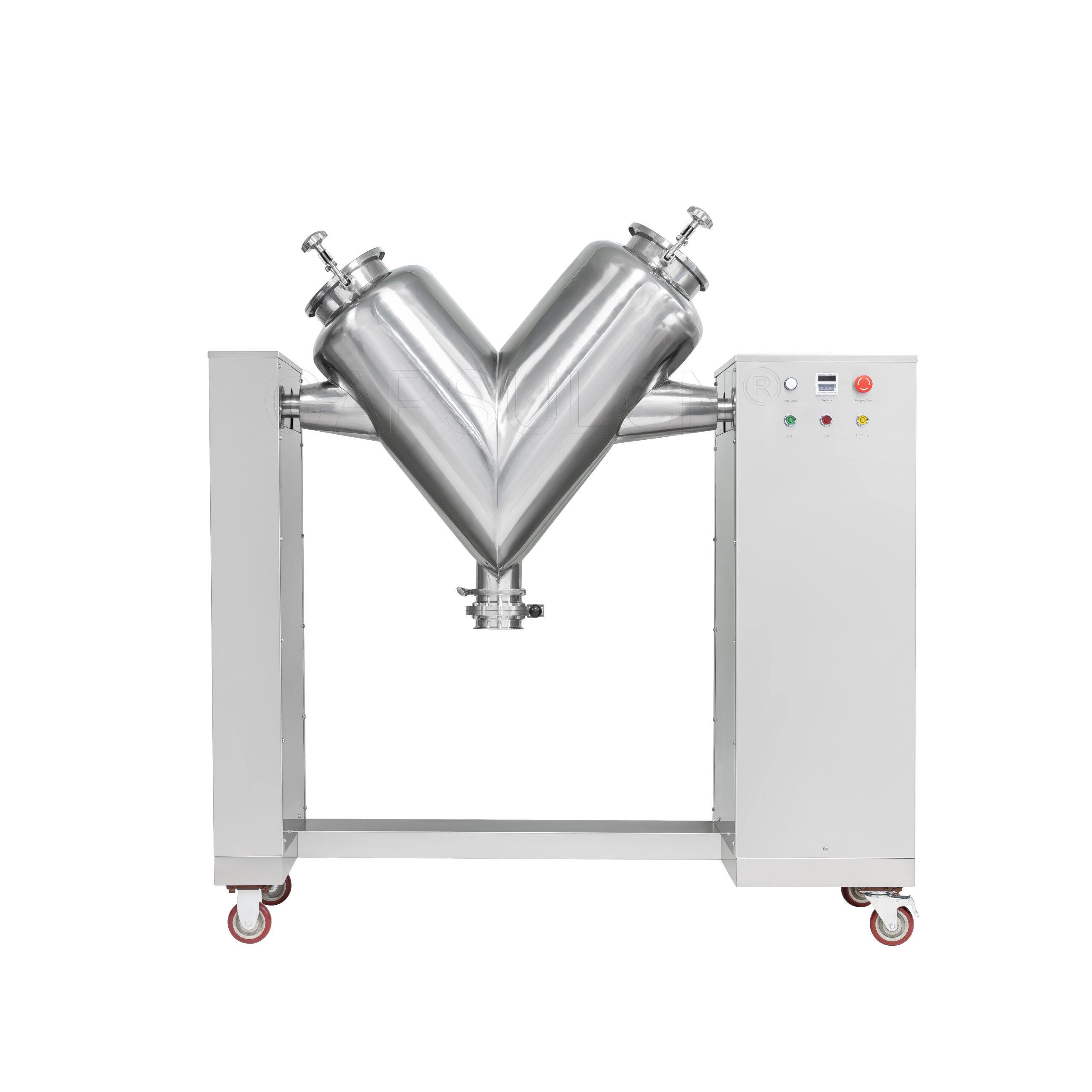

Dry Powder Mixer Blending Machine RawCN-Mix V100(with universal wheels)

Dry Powder Mixer Blending Machine Mixer V100 (with universal wheels) is a mixing machine launched by CapsulCN. This machine is suitable for mixing various dry powder and granular materials in pharmaceutical, chemical, food and other industries. The invention has the advantages of simple structure, convenient operation, beautiful appearance and the like. The parts in contact with the material are all made of stainless steel and meet the CGMP standard.

Working Principles:

There is a motor and a speed reducer installed at the right side. The motor drives the speed reducer through a belt. Then, the reducer drives the V-shaped mixing cylinder to work via coupling. As a result, the powder in the V-shaped mixing cylinder is mixed back and forth in all directions in the cylinder.

Operation and Maintenance:

Before operating the machine, the operator must be familiar with the contents of this manual, the working performance of all parts of the machine and the functions of different buttons on the operation panel.

- Connect the power supply conforming to the machine voltage, press the yellow button “inching” on the operation panel, and observe whether the V-shaped mixing cylinder works normally.

- Adjust the working time of the time relay on the operation panel, and then press the green button “Start” to run the machine without materials.

- After the machine stops, press the button “Inching” to adjust the feed inlet to the upper position.

- Loosen the clamp at the feed outlet to add powder, adjust the working time, and press the green button “Start” to run the machine.

- After the machine stops, press the button “Inching” to adjust the feed outlet to the lower position, then loosen the clamp at the outlet and pour out the material.

- Remember to clean the cylinder after use or when replacing mixed materials.

Features:

- imple structure, easy operation, beautiful appearance.

- The parts in contact with materials are made of stainless steel in compliance with CGMP to ensure hygiene and safety.

- The motor has large power and high mixing efficiency, and can mix a large amount of materials in a short time.

- The diameter of the feed port and the discharge port is large, which is convenient for the entry and exit of materials.

- The working principle is simple and reliable, and it can mix materials stably.

- It is suitable for pharmaceutical, chemical and food industries, and has broad application prospects.

Remarks:

- After use, take out the remaining material in the V-shaped mixing cylinder and clean away the residual powder in each part of the machine.

- Clean the surface of the machine with a dry soft cloth. For any place with much dust but out of reach, use compressed air to blow it away.

- While wiping the machine, observe whether there is any loose screw in the machine. Make sure all screws are tightened properly.

| Model | V100 |

| Volume | 100 L |

| Max. filling capacity | 40 L |

| Best filling capacity | 32 L |

| Power supply & Motor power | 380V, 50Hz,0.75kW; 220V, 50Hz, 1.1kW |

| Rotational speed | 15 r/min |

| Dia. of inlet | 160 mm |

| Dia. of outlet | 100 mm |

| Machine dimension | 1570*650*1500 mm |

| Machine weight | 190 kg |

| Operation dimension | 1580*910*1520 mm |

| Packing dimension | 1680*760*1720 mm |

| Packing weight | 235.5 kg |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China