TabCN-Coater600 Pro Efficiency Coater

Coating Machine TabCN-Coater600 Pro

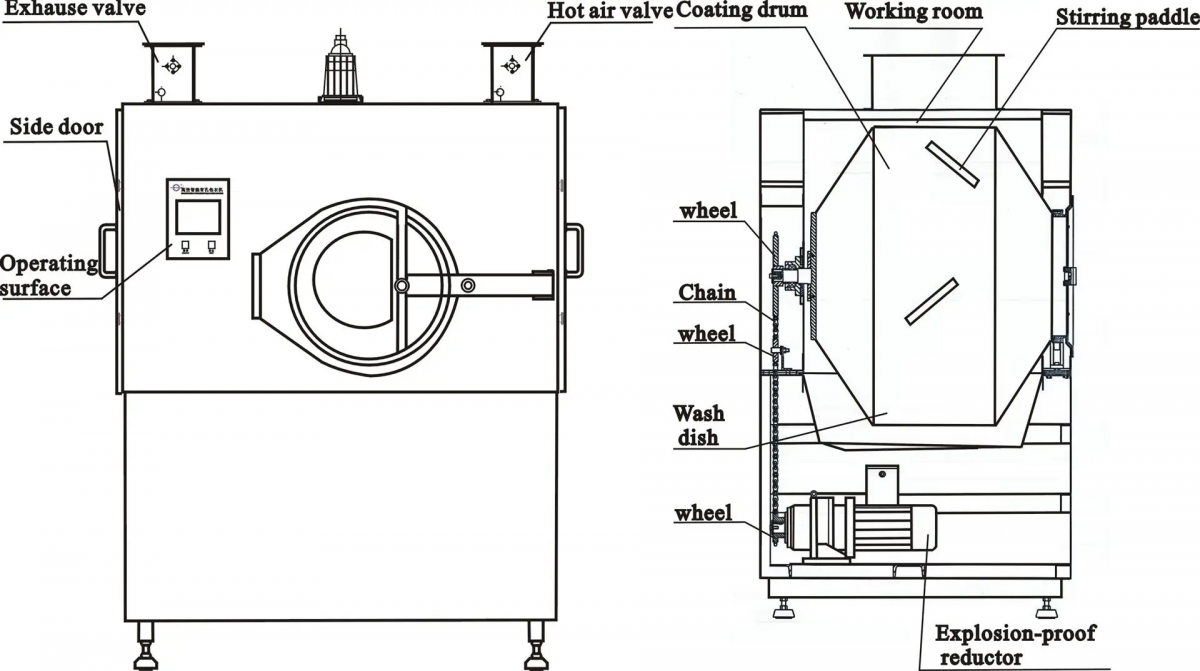

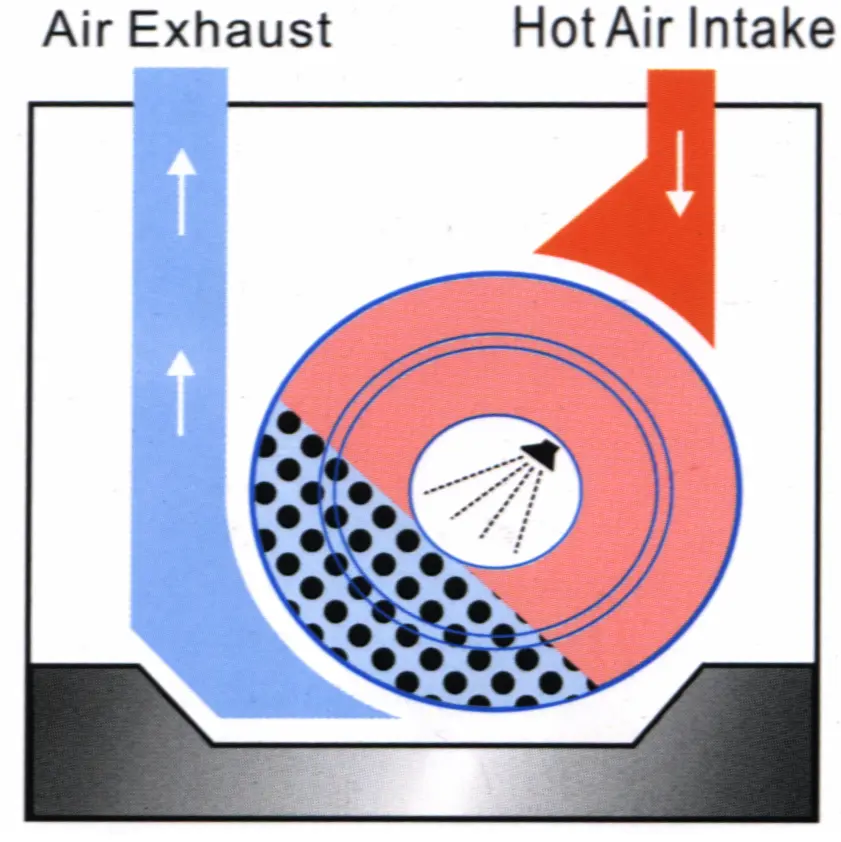

Inside the coating machine rolling drum, the bare tablets are made to move along a consecutive and complicated track. In the process of the motion, controlled by the programming control system, a medium is automatically sprayed (or trickled) to a tablet surface according to the selected technological sequence and parameters by a syrup pump and spraying gun (or a drip pipe for sugar coating). At the same time, finely-filtrated clean hot air from the hot air cabinet penetrates the tablet bed and then is exhausted from the bottom of the drum and discharged after being dedusted so that a solid and smooth film or sugar coating can be quickly formed on the tablet.

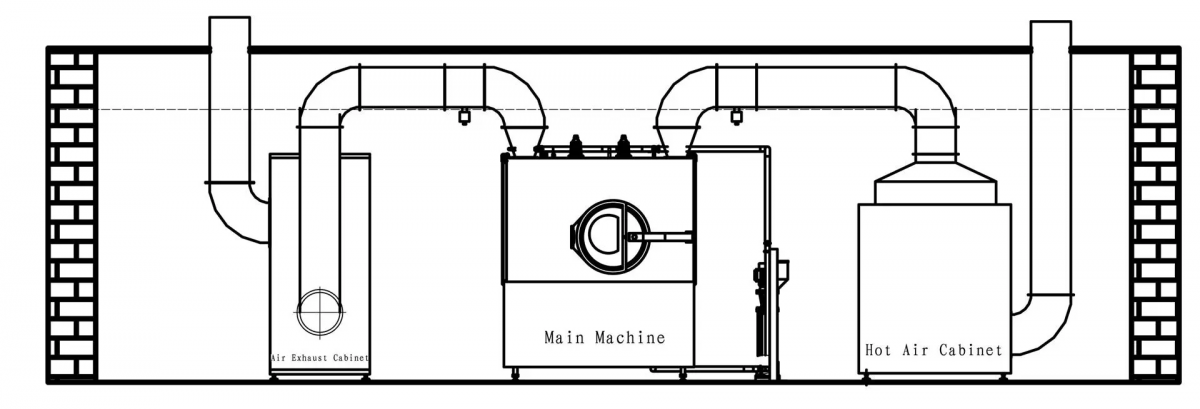

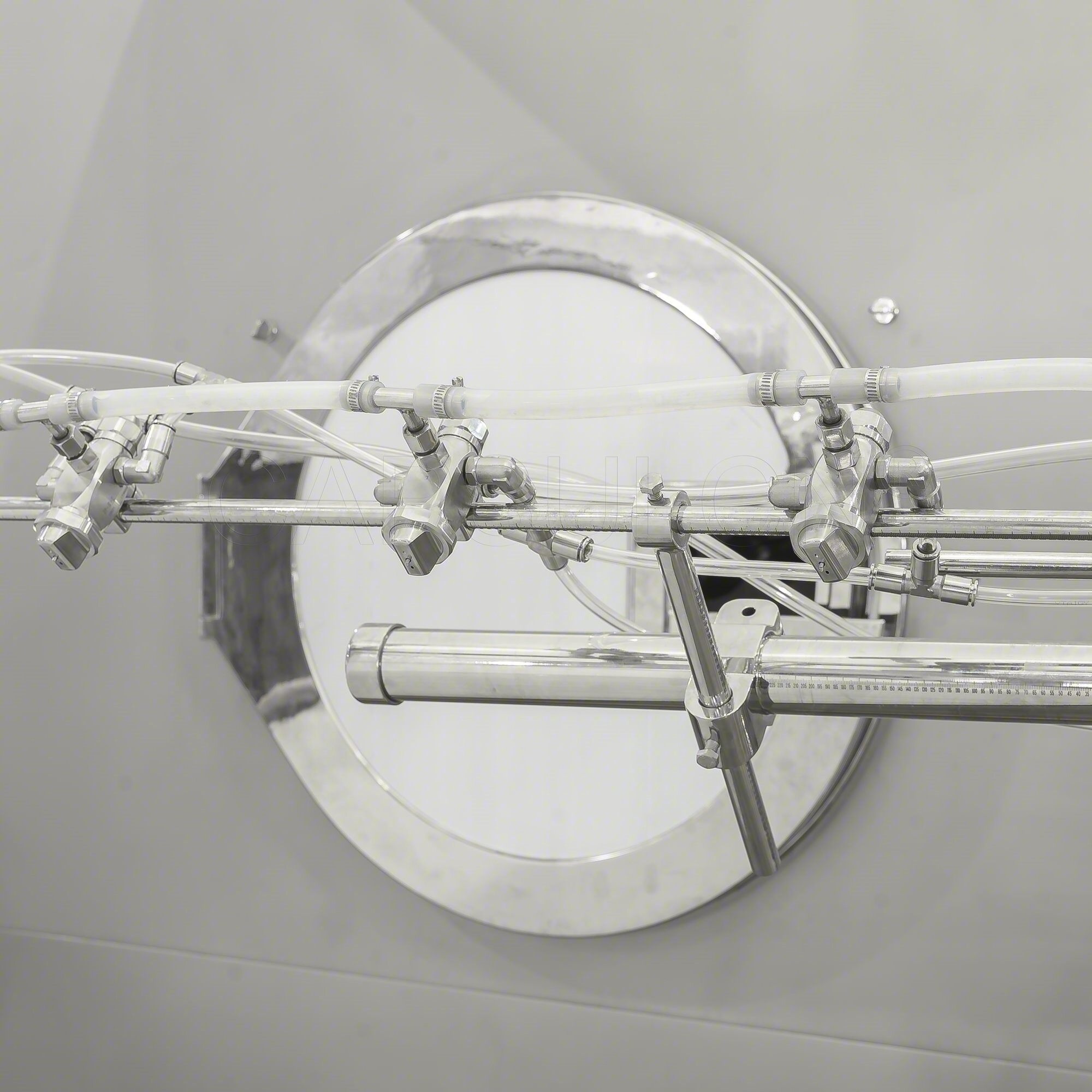

Host machine:It consists of closed operating chamber, sieve type coating drum, agitator, washing disk, driving device, air inlet and outlet valve side door (The side door using gas spring, convenient and lighter).

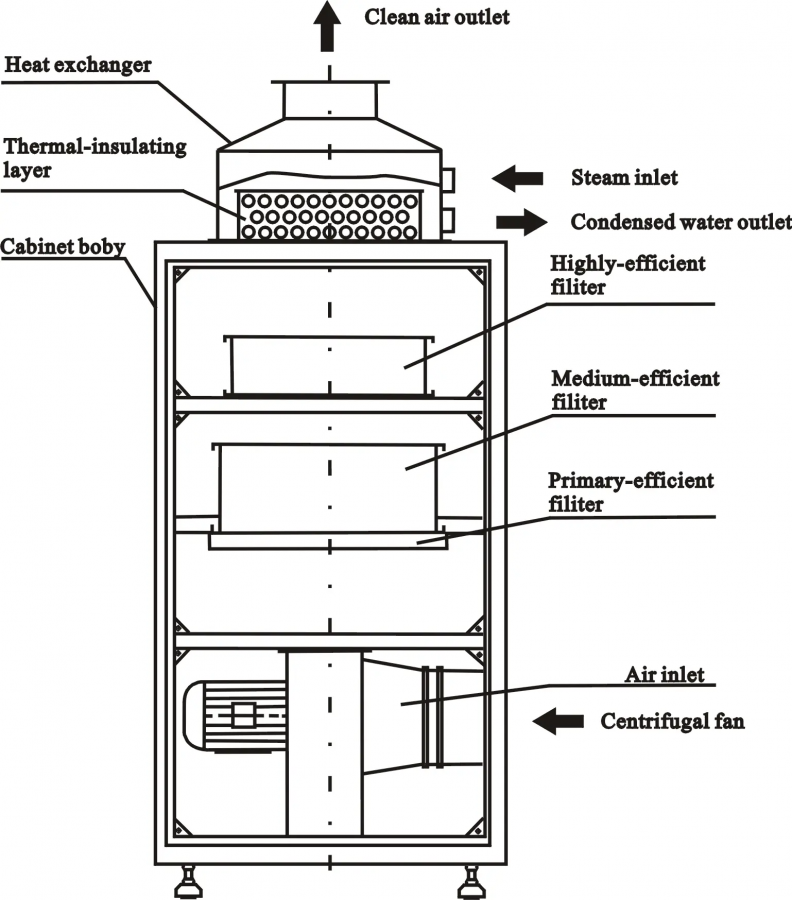

Hot Air Cabinet:The cabinet is made up of cabinet body, frequency conversion speed adjustment, centrifugal fan, filtration system, heat exchanger.

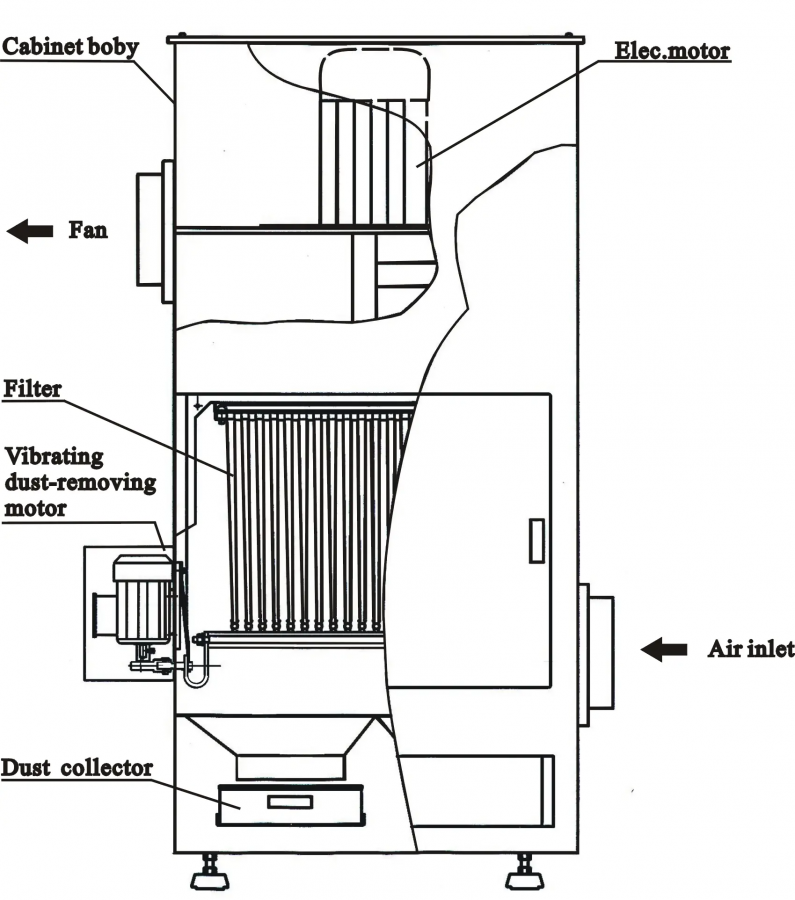

Exhaust Cabinet:The cabinet consists of cabinet body, explosion-proof centrifugal fan, dust-removing filt ration system.

working principles

Inside the coating machine rolling drum, the bare tablets are made to move along a consecutive and complicated track. In the process of the motion, controlled by the programming control system, a medium is automatically sprayed (or trickled) to a tablet surface according to the selected technological sequence and parameters by a syrup pump and spraying gun (or a drip pipe for sugar coating). At the same time, finely-filtrated clean hot air from the hot air cabinet penetrates the tablet bed and then is exhausted from the bottom of the drum and discharged after being dedusted so that a solid and smooth film or sugar coating can be quickly formed on the tablet.

Remarks

- With the PLC control technology adopted, the machine control system is reasonable in design and flexible in programming.

- Auto/manual mode is available for different coating technology.

- The system is featured by high anti-interference capacity, little failures, easy maintenance and good expandability.

| Model | BG-600E |

| Max. tablet volume | 600L |

| Sugar coating drum dia. | Φ1580mm |

| Feed inlet diameter | Φ570mm |

| Sugar coating drum speed | 1-12r.p.m |

| Host machine motor power | 5.5kw |

| Exhaust cabinet motor power | 11kw |

| Exhaust blower air flow | 15450m³/h |

| Hot air cabinet motor power | 5.5kw |

| Air heater air flow | 7419m³/h |

| Air heater temp.-adj. range | ~80℃ |

| Hot air cleanness level | 10level |

| Syrup pump power consumption | 0.55kw |

| Silicon rubber hose | φ9-φ16mm |

| External dimensions of host machine | 2000×2277×2660mm |

| Host machine weight | 2800kg |

| External dimensions of hot air cabinet | 1600×1100×2350mm |

| Hot air cabinet weight | 820kg |

| External dimensions of exhaust cabinet | 1050×1000×2470mm |

| Exhaust cabinet weight | 660kg |

HUADA Pharma Offers

Backed by our 25 years of experience in pharmaceutical engineering solutions, we design, manufacture and supply high quality pharmaceutical process and packaging equipment to the industry worldwide.

Raw Processing Machine

Raw material processing equipment is designed for the initial treatment of powders and granules. Our material processing equipment includes granulator machines, powder sifter machines, powder grinder machines, etc. These equipment are widely used in the pharmaceutical, food, chemical and other industries.

Tablet Press Machine

A tablet press machine is used to compress powder into tablets with consistent size and weight. A tablet pressing machine can be used to manufacture tablets of a wide variety of materials, including pharmaceuticals, candies, food, industrial pellets and cosmetics.

Capsule Filling Machine

Our professional capsule filling machines can fill a variety of materials such as powders, granules or liquids. The industrial capsule filling machines play an important role in many fields such as pharmaceuticals, herbal medicines and health products. The capsule fill machine greatly improves the productivity of medications. Huada Pharma combines modern capsule filling technology with mechanical simplicity and robustness, and adopts ergonomic design to create durable and reliable machines that meet strict cGMP standards.

Softgel System

The HUADA Pharma softgel production system is a space saving, stand alone, all-in-one softgel encapsulation system capable of full production duties.

Pill Counting and Filling Machine

Huada Pharma's counting line includes various types of pill counting machines and pill bottle filling machines. Our automatic pill packaging machines can optimize your production by ensuring precision and high speed.

Blister Packaging Machine

Blister pack machines are specially designed to pack various products such as tablets, capsules, liquids, pill and more, into blisters. Blister packaging can package any special-shaped products. This packaging method is convenient for transportation and has good sealing performance. Therefore, blister packaging machines are widely used in many industries such as the pharmaceutical industry, food industry, and cosmetics industry.

Contact HUADA Pharma

Get in touch with us today to discuss your project and how we can help you fully realize its potential.

HUADA Pharma

WhatsApp+86 159-6772-7111

info@huadapharma.com

Rm.1888 Bld 2nd Zhongrun Square

Ruian, Zhejiang, China