Blending is important in making capsules, powders and chemicals. It guarantees the ingredients are evenly distributed in the final product. If you struggle to choose the right machine to mix dry powders, read the post and find a wise choice.

What is a Dry Powder Blending Machine?

This machine is used to mix different dry powders evenly. It is similar to when you're baking a cake. You need to mix flour, sugar, and cocoa powder. A machine can release hands and mix more evenly. In industries, a dry powder blender works the same way but on a much larger and more professional scale. Because precise mixing is critical for product quality. A mixing machine can handle powders with different textures, densities, and sizes. They have various rotating mechanisms, like blades or paddles, for processing.

This equipment has a wide range of applications. In pharma, medicine powders should be mixed uniformly so every tablet or capsule has the same effect. In cosmetics, there are many powdered makeup products like eyeshadows, and blush. They require to blend pigments, fillers, and additives thoroughly. This machine is also applied in food industry. Seasonings and drink powders should be mixed to meet customers.

Six Common Types of Dry Powder Mixing Machines

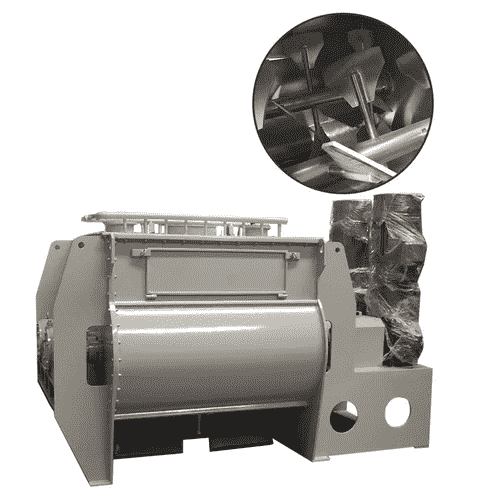

Ribbon Blenders

This type has a horizontal chamber with spiral ribbons inside. These ribbons rotate to mix powders. The inner ribbon pushes materials one way, while the outer one pulls them back. So all materials get evenly blended. Ribbon blenders are perfect for large batches of powders, like mixing flour and additives in the food industry. They’re also great for powders with similar densities. Because the movement is gentle enough to avoid breaking delicate particles.

V Blenders

V blenders feature V-shaped chambers to tumble powders as they rotate. It is similar to toss your laundry in a dryer. That’s how the powders move and mix. V blenders are ideal for smaller batches or sensitive materials, like pharmaceutical powders. Because these machines conduct gentle handling. It won’t generate too much heat or pressure, so it keeps fragile ingredients intact. However, it doesn’t suit powders with different particle sizes for processing. The lighter powders may settle at the bottom, while the heavier powders rise to the top. This will cause uneven mixing.

Bin Blenders

Bin blenders mix powders directly in storage containers. The container is mounted on the machine, and it can be removed. This design makes cleaning easier and avoid contamination risks. So they are mostly used in pharmaceuticals to make tablets. They’re also efficient, allowing quick batch replacement and processing.

Double Cone Mixers

Double cone blenders have a rotating, cone-shaped chamber. It spins powders into a thorough blend. They’re highly efficient for free-flowing powders, like spices or fertilizers. Because of the unique shape, there are no dead spots where powders might get stuck. This is crucial for maintaining consistency in large batches. In addition, their design makes them easier to clean than some other types.

Paddle Blenders

Paddle blenders are top choice for sticky or dense powders. They are equipped with flat paddles rotating inside the chamber. It makes mixing thoroughly while also breaking up clumps. These machines are often used in baking. Because ingredients like sugar or fats might clump together. The paddles make sure the blend is smooth and evenly distributed.

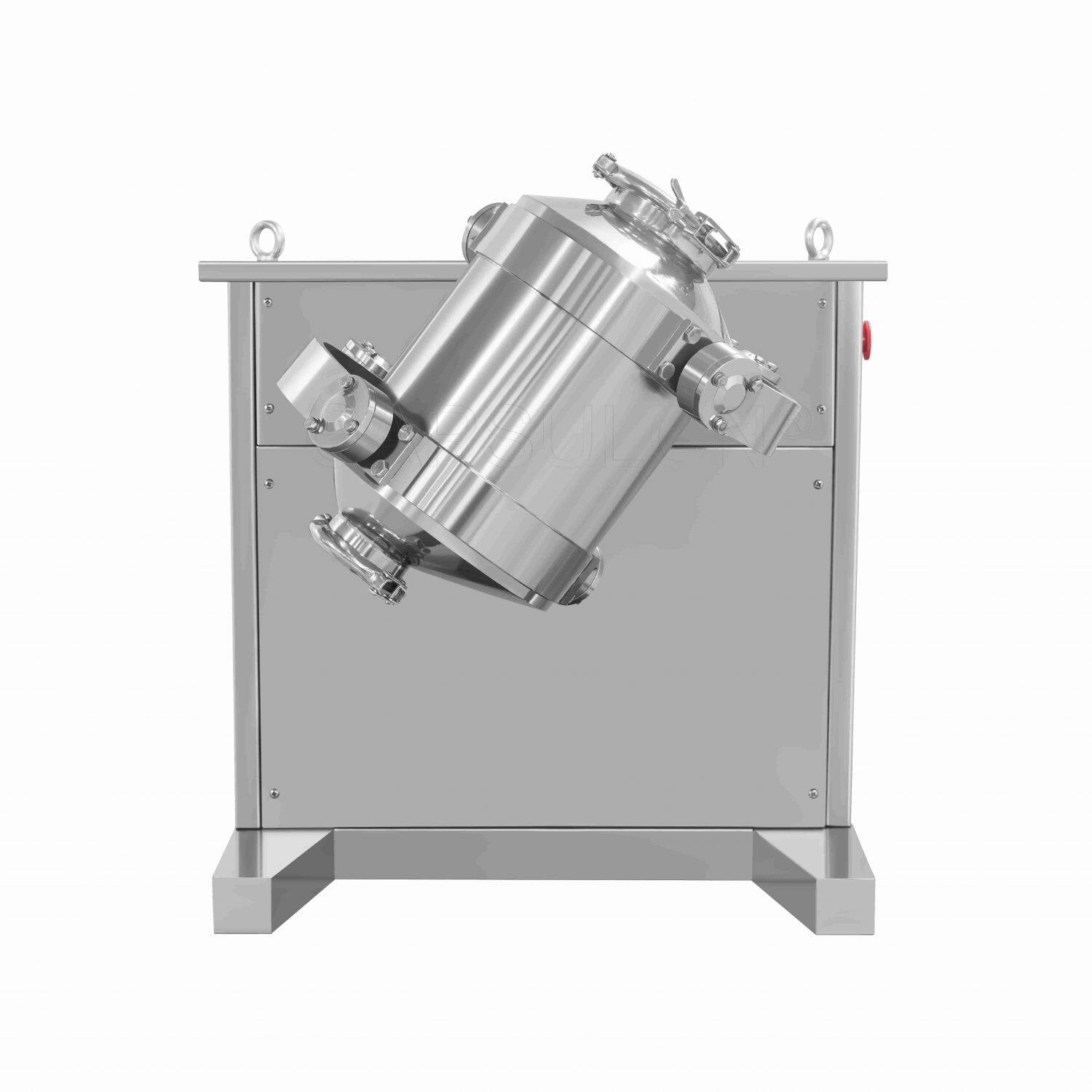

3D Powder Mixers

This mixer moves powders in three-dimensional directions, like up, down, left, right, and around. It seems like a cube tumbles inside a rotating chamber. They are especially suitable for applications that require fine mixing and high precision. It makes sure that each particle contacts evenly with the other particles. This continuous multi-angle motion ensures that every particle meets and blends uniformly. This unique movement eliminates no powder might settle and guarantees a thorough, consistent mix.

How to Choose a Blender for Dry Powders?

Material Types

Powder types are the most important factor that should be considered. Different properties suit different blender types. For example, Free-flowing powders like salt or sugar work well with ribbon or V blenders. Their mixing method is more basic. This makes them suitable for powders with similar particle sizes. Sticky or dense powders are better suited for paddle blenders, as they can break up clumps. As for sensitive or fragile powders, they may require a 3D blender for gentle handling.

Production Sizes

Each type of blender is designed to handle different production scales, so a right one can significantly impact efficiency and cost-effectiveness. For small business, such as in a research lab, V blenders and double cone blenders are excellent choices. They are both compact and won’t cover too much space. For large-scale production, you’d better choose ribbon blenders or bin blenders. Their design allow high-capacity blending evenly.

How to Maintain a Dry Powder Blender?

Regular Cleaning

Cleaning is especially important in industries like pharmaceuticals and food. If without a thorough cleaning, it may lead to quality issues or safety risks. After each use, you’d better clean the interior and surface of the chamber. For thorough cleaning, you can use a vacuum or compressed air to remove any leftover powder. But you should be cautious not to damage the ribbons or the motor components during cleaning.

Regular Check and Lubrication

For better performance, regular inspections and lubrication are necessary, especially for machines with moving parts. Some parts may wear out over time, so you need inspect them regularly for cracks, rust, or loose parts. If there is any issues, you should replace worn-out components promptly to prevent further damage. For smooth operation, you need to lubricate the key moving parts, such as bearings and motors.

Calibration

If your blender is equipped with sensors to monitor mixing speed, temperature, or load, these sensors should be calibrated regularly for accuracy. You can follow the manufacturer’s guidelines for sensor calibration.

Upgrade Your Mixing Efficiency with HUADA Pharma

If you need high-quality mixing machines for dry powder, a reliable supplier is important. As a leading equipment manufacturer in China, HUADA Pharma has helped thousands and hundreds of clients. We offer a wide range of blenders and also support customization. You can tell us your requirements in detail, and we will meet your needs quickly and correctly.