Solid dosage forms have become the most commonly used pharmaceutical products due to their convenience, stability, and ease of administration. This article will show you definition of solid dosage form, solid dosage forms types, advantages and disadvantages of solid dosage form.

What is a Solid Dosage Form?

The solid dosage forms definition is simple; it refers to the type of drug that exists in solid form. They are prepared by mixing active drugs with appropriate excipients. Common pharmaceutical solid dosage forms are tablets, granules, powders, capsules, and films. In most cases, solid dosage forms are taken orally, but in special cases, they can also be taken through other routes. Oral solid dosage forms are often safer than other routes. Solid dosage forms have a wide range of uses and are one of the most common drug forms in the modern pharmaceutical field.

Types of Solid Dosage Forms

There are many classifications of solid dosage forms in our daily lives. Different treatment needs will require different types of solid dosage forms. Below we will introduce you to several common solid dosage forms examples and their applications.

1. Tablets Solid Dosage Forms

Tablets are the most common type of solid dosage form and come in a variety of shapes and sizes. Oral solid dosage forms tablets are usually used for oral administration and come in a variety of forms, such as regular tablets, sustained-release tablets, chewable tablets, etc. The oldest solid oral dosage forms are Tablets.

2. Capsules Solid Dosage Form

Capsule solid dosage form refers to encapsulating the drug in a gelatin shell. Capsules come in different forms: hard capsules, soft capsules and enteric-coated capsules. This type of solid dosage form can effectively mask the unpleasant taste or odor of some drugs, is easy to swallow, and can also improve drug stability. Compared with tablets, capsule solid dosage forms are more suitable for drugs that need to be released quickly. Examples of capsule solid dosage forms are cephalexin capsules, omeprazole capsules, etc.

3. Granules Solid Dosage Form

Granules solid dosage form refers to drugs in the form of granules. They can be taken directly or dissolved in water easily. Granules solid dosage form allow for more flexible dosage adjustments than tablets and capsules. Granules are more stable than powders under certain conditions. And, compared with powders, they can reduce the risk of inhalation during the manufacturing process and are easier to handle. Antibiotic granules for pediatric suspension are a type of granules solid dosage form.

4.Powders Solid Dosage Form

Powders solid dosage form are drugs that come in fine, dry powders, such as oral rehydration salts (ORS) for dehydration. It usually needs to be mixed with water or other liquids before consumption. Powders solid dosage form of drugs can be customized to individual needs. Some patients who have difficulty swallowing tablets or capsules may prefer powders solid dosage form. However, it has a disadvantage that it is easily susceptible to moisture and contamination.

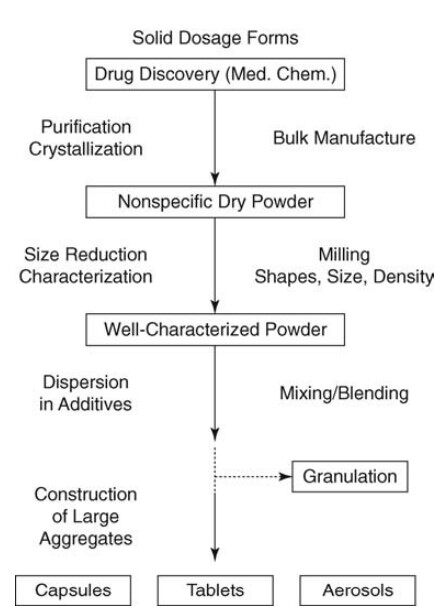

Solid Dosage Form Manufacturing Process

The manufacturing process of solid dosage forms is a delicate process, covering multiple steps from raw material preparation, raw material mixing, granulation, tableting, etc. Each step is crucial to ensure the quality and efficacy of the final drug.

1. Raw Material Preparation

Raw material preparation is the basis of the entire manufacturing process. According to different formulations of solid dosage forms, all active pharmaceutical ingredients (API) and excipients used in solid dosage forms are accurately weighed.

2. Granulation and Drying

This step is to process the drug powder into granular materials through a granulator. Common granulation methods include wet granulation or dry granulation. Wet granulation forms wet granules by adding a certain amount of solvent to make the drug powder stick together. Then it is dried to remove excess liquid. Dry granulation does not use liquid, but compresses the drug powder into granules through mechanical pressure. This method is suitable for drugs that are sensitive to moisture.

3. Tablet Compression or Encapsulation

After granulation is completed, the drug is converted into different forms such as tablets or capsules according to its different uses. This process uses a pill tablet press machine to press the granules into tablets with uniform shape and accurate dosage. Capsule manufacturing uses capsule fillers to fill a fixed dose of particles into capsules of suitable size.

4. Tablet Coating

Some tablets also require a pill coating machine to apply special coatings, such as sugar coating or other functional coatings. Sugar coating is mainly used to improve the taste and appearance of drugs, which makes tablets easier to swallow. Functional coatings can enhance the stability of drugs or achieve special functions such as controlled release. For example, enteric coating is used to ensure that drugs are released at a specific location in the gastrointestinal tract to avoid irritation to the stomach.

Advantages and Disadvantages of Solid Dosage Form

Solid dosage forms of drugs have become popular due to their stability, portability and precision. Different dosage forms of drugs have their own advantages and disadvantages. Below are the solid dosage forms advantages and disadvantages.

Advantages of Solid Dosage Forms

1. High Stability

Solid dosage forms are usually more stable than liquid dosage forms. They are not prone to decomposition or microbial contamination during daily storage, so the shelf life of the drug is relatively long.

2. Accurate Dosage

The drug content in each tablet or capsule is fixed after precise measurement. Therefore, it will not cause the problem of insufficient or excessive drug intake.

3. Easy to Carry and Take

Unlike liquid dosage forms, solid dosage forms of drugs are small in size and light in weight. Patients can easily take the drug even when they are away from home, as this solid dosage form does not require additional solvents for dilution.

4. Controlled Release

Different formulation processes can achieve rapid release, sustained release or controlled release. The drug can be released in a specific part or act for a long time.

Disadvantages of Solid Dosage Forms

1. Not Suitable for All Patients

Solid oral dosage forms are not suitable for patients with difficulty swallowing, such as children or the elderly. It may cause difficulty in taking medicine.

2. Slower Effective Time

Because oral solid dosage forms require dissolution and absorption from the gastrointestinal tract before they can take effect, their effectiveness is usually slower than liquid dosage forms.

3. Inability to Flexibly Adjust the Dosage

The dosage of solid dosage forms is fixed and cannot be adjusted according to the specific needs of the patient. This is a big difference between solid and liquid dosage forms.

4. Possible Gastrointestinal Irritation

Some drugs in pharmaceutical solid dosage forms may cause discomfort or side effects to the gastrointestinal tract. For example, taking certain nonsteroidal anti-inflammatory drugs (NSAIDs) can irritate the gastric mucosa.

Conclusions of Solid Dosage Forms

There are many different pharmaceutical solid dosage forms. In addition to solid and liquid dosage forms, there are also semi-solid dosage forms. There are many different dosage forms for drugs. In addition to solid and liquid dosage forms, there are also semi-solid dosage forms. Of course, they have different differences and uses. Each dosage form meets different patient needs according to its characteristics. It is widely used in the treatment of various diseases.